Participating members of the UCMTF that will be attending ITMA 2023 are Fil Control, Petit Spare Parts, Hemp-Act, Superba, Aesa Air Engineering, NSC, Ebelmann, Mallein, Schaeffer Productique, Callebaut De Blicquy, Hannecard, Alliance Machines Textiles, Spoolex, Dollfus & Muller, Texti Sonics, and Rousselet-Robatel, UCMTF said in a press release.

Sensor’s expert since 1990, Fil Control specialises in developing, producing, and selling equipment devices for the textile machinery industry. It will be presenting its latest developments using electro-mechanical, optical, inductive, and reflective technologies in Hall 2, C 305.

Petit Spare Parts, which will be presenting in Hall 2, C 306, holds the exclusive worldwide trade of the original spare parts for all ICBT fine count machines. Petit Spare Parts not only sells parts from catalogues, but also provides solutions regardless of equipment type and location.

Based on 20 years of expertise in the field of extraction and valorisation of hemp textile fibres, Hemp-Act will be launching the marketing of its brand-new textile decorticating line at ITMA 2023 in Start-Up Valley, Hall 3, A 201a. It is therefore a complete and modular solution that Hemp-Act offers to propel into this new sustainable economy of textile hemp.

Superba is well known for its advanced heat-setting solutions. This is why this year two strategic innovations, KR1 & MCD3(M), will be set out in Hall 3, B 205b at ITMA 2023.

Aesa Air Engineering, which will be presenting in Hall 3, D 305, offers the latest generations of monitoring systems allowing remote control and energy optimisation through state-of-the-art all-inclusive solutions. Aesa focuses on predefined patterns for optimising the room control system and anticipation of the room fluctuation, and optimising consumption through inverter drive system.

NSC is the global specialist in textile machines for processing long staple fibres such as wool and wool-like fibres. The company will be presenting the ERA 50 combing machine, GC 50 chain gill, and new flyer frame BM 21 in Hall 3, E 101.

Established in 1981, Barbier-Ebelmann is now a world-renowned specialist in special cutting devices and hard materials’ machining. In close partnership with their customers, Ebelmann finds solutions to fix cutting problems specially when technical fibres like glass, aramid, and carbon fibres are involved. The company will be presenting in Hall 6, A 211.

With 77 years of experience, Mallein is a specialist of the beams for warping and weaving and able to answer to all textile activity needs. Mallein will exhibit some of its new aluminium canisters at ITMA 2023 in Hall 6, B 206. It will also be exhibiting new flanges developed for specific customer applications.

Schaeffer will introduce its new textile business information system SolinWai in Hall 9, B 210. Faced with an increasing hybridisation of the information systems, the digital solutions offered to textile companies by Schaeffer open up vast areas of improvement in industrial and business processes.

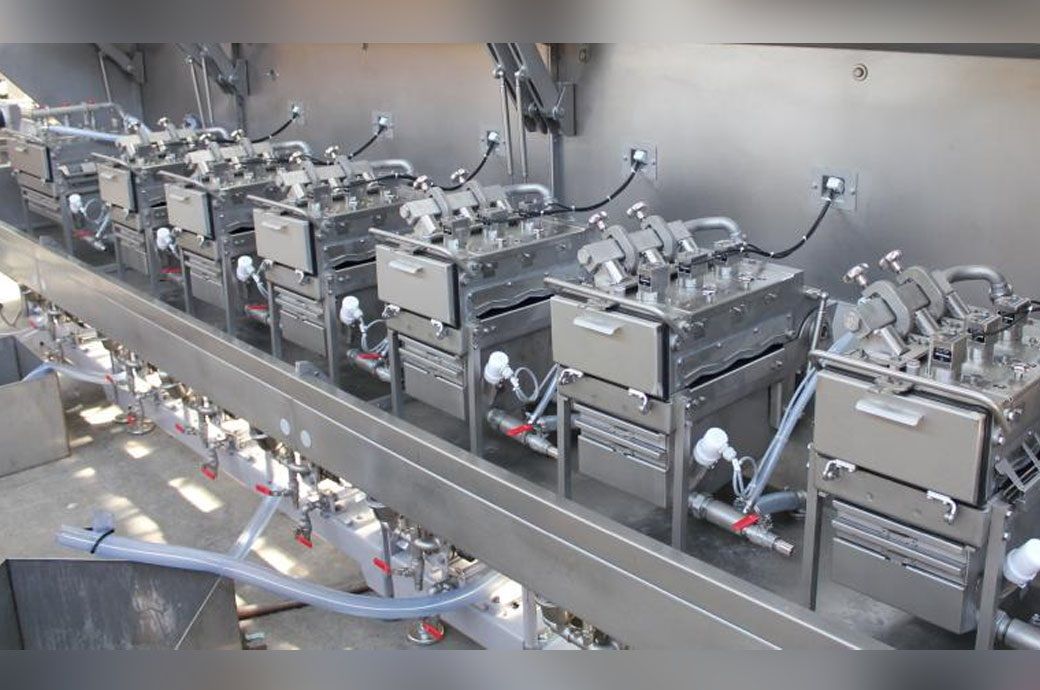

Callebaut De Blicquy, which will present in Hall 10, A 310 c, designs and produces complete units for bleaching and dyeing any type of fibre or application including wads, cables, bumps, and coils. It specialises in solutions that reduce the amount of raw materials, water, and energy used while maintaining peak productivity and quality.

With more than 120 years of experience, Hannecard, which will present in Hall 11, A 201, is the European leading supplier of industrial roller coverings in rubber, polyurethane, composite, and carbide to various sectors. It also offers a wide range of other services, from roller maintenance to roller repair and roller optimisation.

Alliance’s Jeta UF and Natura DS will embed internet of things (IOT) connectivity as well as a brand-new automation platform able to host future dyeing AI. In addition to the manufacturing of several machine types, Alliance Machines Textiles company, which will be presenting in Hall 11, C 201, also supplies spare parts and offers quality aftersales service.

Calemard, is the converting machinery division of Spoolex, which will be showcasing in Hall 14, B 203. Present since 1955 in a wide range of markets, Calemard has focused its activities on highly technical slitting applications. Always based on modular design, each Calemard’s slitter is multi-purpose and can convert thick or thin materials into pads or spools of wide or narrow strips.

Dollfus & Muller, which will be presenting in Hall 14, C 104, is a leading manufacturer of endless felts and dryer belts especially for the textile finishing and tanneries. Dynajet is a sales department of Dollfus & Muller specialised in fabrics for ink jet printers and wide widths fabrics for theatre and events.

Texti-Sonic, which will be presenting in SAS Hall 18, A 107, designs and manufactures a specific range of ultrasonic welding and sealing/slitting devices for FIBC industries, machines, and looms manufacturers, packaging, technical textiles, geotextiles, non-woven, medical, awnings, plastics, flexible products. These devices offer a great technical versatility for straight or curved operations, or multi layers in continuous assembling, in multi-spots sealing, joining end to end narrow or wide webs.

Since 1905, Rousselet-Robatel, which will be presenting in Hall 18, A305, manufactures centrifuges for use in the textile industry which include continuous centrifugal hydro-extractors and batch centrifuges with interchangeable baskets for loose stock fibres, bobbins, and textile fabrics. At the test facility in Annonay, preliminary studies can be performed using the latest centrifugal technology according to the customer’s specific process, added the release.

Christian Guinet, secretary general of UCMTF, said: “We are driven by their entrepreneurial spirit. Our members embrace innovations to shape together and achieve a perfect alignment between their future and the future of their customers.

“Before welcoming our customers at ITMA, I would like to share with you a proud moment for French Textile Equipment. Kristian Blummenfelt, the Norwegian athlete won the men’s triathlon Olympic gold medal. The Trimtex Skinsuit he was wearing for swimming, cycling, and running was made of a fabric designed and produced by a French company. To produce the very fine and technical fabric which incorporates an unusually high percentage of elastane covered polymer, a specific equipment from one of our members was needed. A highly technical finishing equipment for a highly technical fabric and, at the end of the story—a gold medal! Our members will deserve many such medals at ITMA in MilanG. Let’s tell all our visitors that we will be very honoured to welcome them.”

Fibre2Fashion News Desk (NB)