The non-profit H&M Foundation and the Hong Kong Research Institute of Textiles and Apparel (HKRITA) together have found groundbreaking solution to recycle blend textiles into new fabrics and yarns, without any quality loss, through a hydrothermal (chemical) process. The technology will be scaled up and made available to the global fashion industry.

The finding is the result of the four-year innovative partnership between the two organisations. It is a major breakthrough in the journey towards a closed loop for textiles.The non-profit H&M Foundation and the Hong Kong Research Institute of Textiles and Apparel (HKRITA) together have found groundbreaking solution to recycle blend textiles into new fabrics and yarns, without any quality loss, through a hydrothermal (chemical) process. The technology will be scaled up and made available to the global fashion industry.#

"For too long the fashion industry has not been able to properly recycle its products, since there’s no commercially viable separation, sorting, and recycling technology available for the most popular materials such as cotton and polyester blends. This very encouraging finding has the potential to change that. We are very excited to develop this technology and scale it beyond the laboratory, which will benefit the global environment, people and communities," says Erik Bang, innovation lead at H&M Foundation.

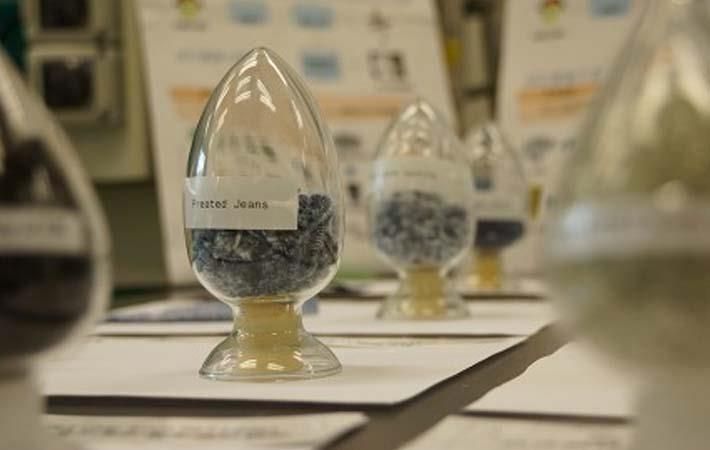

The aim of the Closed-Loop Apparel Recycling Eco-System Programme is to find at least one ready technology to recycle clothes made from blend textiles, within the four-year project period. One year into the partnership, HKRITA has together with Ehime University and Shinshu University in Japan, successfully developed a hydrothermal (chemical) process to fully separate and recycle cotton and polyester blends. The recovered polyester material can be reused directly, without any quality loss.

The hydrothermal process uses only heat, water and less than five per cent biodegradable green chemical, to self-separate cotton and polyester blends. This fibre-to-fibre recycling method is cost effective, and there’s no secondary pollution to the environment, ensuring the life of the recycled material is prolonged in a sustainable way. The technology will be licensed widely to ensure broad market access and maximum impact.

“By being able to upcycle used textiles into new high value textiles, we no longer need to solely rely on virgin materials to dress a growing world population. This is a major breakthrough in the pursuit of a fashion industry operating within the planetary boundaries,” Edwin Keh, Chief Executive Officer of HKRITA, says.

The hydrothermal process uses only heat, water and less than five per cent biodegradable green chemical, to self-separate cotton and polyester blends.

The H&M Foundation initiated the partnership with HKRITA in September 2016. It is backed by an estimated 5.8 million euros of funding, with HKRITA conducting the research and work to commercialise the outcomes. The Innovation and Technology Fund of the Hong Kong SAR Government also provides additional substantial funding and support. The total project investment is estimated to around 30 million euros during the four-year collaboration (2016-2020), which makes it one of the biggest and most comprehensive efforts ever for textile recycling.

It is H&M's customers’ engagement that have enabled this important research, as the exact financial contribution is determined by the annual surplus from H&M’s global in-store garment collecting programme, which is donated to H&M Foundation. To date the H&M Foundation has donated 2.4 million euros to HKRITA. (SV)

Fibre2Fashion News Desk – India