With core competencies in shedding (cam motions, dobbies, and jacquard machines) and weaving preparation (drawing-in, leasing, and warp-tying machines), Staubli plays an important role in the design and quality of woven end-products, the company said in a press release.

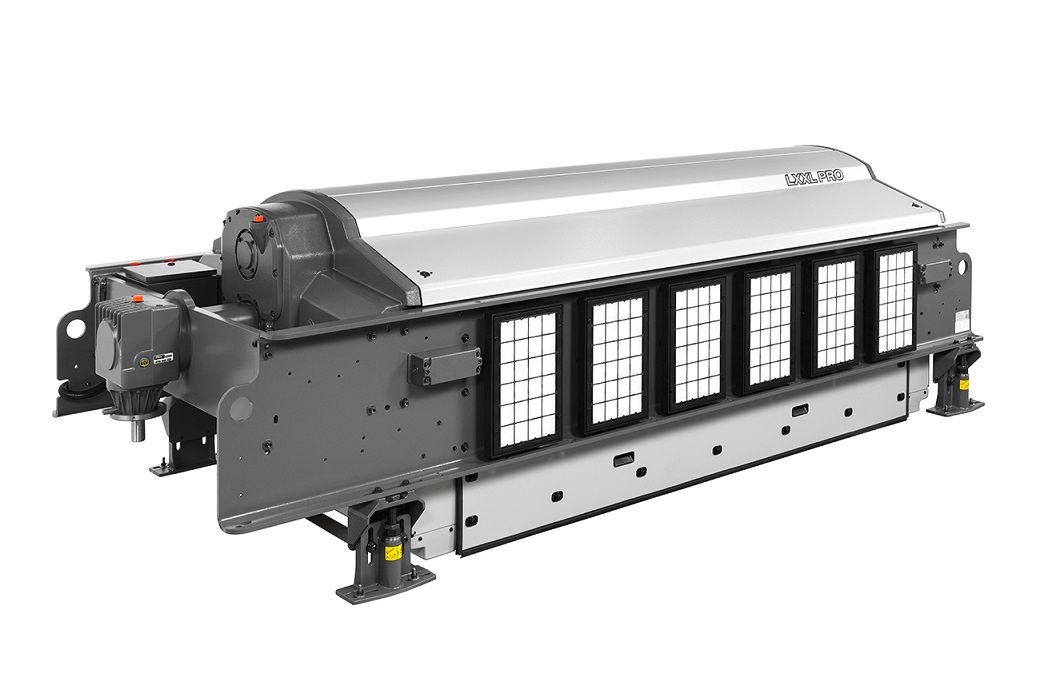

Some of the Staubli products being exhibited in the weaving hall are the Safir S60 automatic drawing-in system with Active Warp Control 2.0; shed formation solutions for frame weaving; LX Pro, LXL Pro, and LXXL Pro jacquard machines; Alpha carpet weaving system; and MyStaubli Portal.

The Safir series of drawing-in systems offers unique advantages for efficient style changes. With its Active Warp Control technology, Staubli has been setting standards in yarn recognition and management for many years. At ITMA 2023, Staubli will present the next generation of this technology—Active Warp Control 2.0. Visitors to the booth can observe an automatic drawing-in system in operation with this impressive technology.

If one needs a high-speed weaving solution that offers top reliability and adaptability, then they should check out the 1600/1700 series of cam motions and the S3000/S3200 series of electronic rotary dobbies. Staubli’s broad product range answers the latest market demands and customer requirements and wishes, included reduced maintenance. The design of Staubli machinery increasingly takes environmental performance into account. For instance, the latest machines offer reduced oil volumes and fewer oil changes. ITMA visitors will learn more about this and other innovations featured in Staubli’s electronic rotary dobbies and cam motions.

The Pro series of jacquard machines was launched at the end of 2022. These machines have already convinced jacquard weavers around the world who seek top energy efficiency in the production of flat, terry, or OPW (one-piece woven) fabrics. Available in formats ranging from 4,608 hooks (LX Pro) to 25,600 hooks (LXXL Pro), these jacquard machines feature Staubli’s exclusive Noemi electronics architecture and the state-of-the-art MX Pro module. This combination perfectly integrates the constraints of high-speed weaving, temperature, and the significant number of hooks to be lifted. ITMA visitors will see three complete jacquard installations in operation producing trendy fabrics and learn all about the advantages and benefits these machines provide.

Staubli will be introducing a new carpet weaving system at ITMA. Certain to be a highlight of the booth, the new Alpha carpet weaving system will be in operation every hour producing rugs. It features numerous newly developed components never before exhibited. Visitors can walk across the weavers’ stand and observe the double carpet production.

Staubli will also present its new customer portal at ITMA 2023, MyStaubli. As a new key to machinery solutions, this platform offers personal access to online information about Staubli’s range of solutions and services. Visitors will learn about the many benefits the new portal offers, added the release.

The Staubli booth will provide a comprehensive overview of the company’s range of solutions for future-oriented weaving mills. Staubli is committed to remain in close contact with its customers and meet market requirements as a partner. The Staubli team looks forward to presenting their latest solutions and innovations and discussing visitors’ individual needs and wishes for cost-effective and highly productive textile manufacturing.

For over 130 years, Staubli has been a leading provider of premium quality products and services for sustainable improvements in industry and society. Staubli’s reliability and stability are based on uninterrupted family ownership, and the company’s technical excellence is the result of a continuous focus on industrial customers. This is all part of one strategic goal—to develop solutions for safer, more efficient, and more economical industrial processes.

Staubli offers new and improved high-performance systems and solutions for processing fabrics for fashionwear, home fabrics, carpeting and automotive, protection, and medical applications, as well as highly complex technical textiles for future applications.

Fibre2Fashion News Desk (NB)