European industrial textile machineries manufacturers understand they must necessarily seek competitiveness through innovation and environmental sustainability. In fact, it is the only way to remain a market leader in a highly competitive international context. Ferraro Spa, a leading company that has been operating for over 70 years in the textile finishing sector, both knitted and woven, with thousands of plants all over the world, believes that, as never before, innovation must go hand in hand with sustainable development. The theme has become guiding element of the company’s vision and an integral part of our daily lives, requiring us to adopt circular economy processes, reduce emissions, reduce energy from non-renewable sources and ‘greening’ both production processes and products.

Since its inception, the company has been a supporter of the ACIMIT (Italian Association of Textile Machinery Manufacturers) Green Label project: an internationally recognised, successful certification that, through targeted redesigning of the machinery itself, aims to reduce energy consumption across the board and thus CO2 emissions, i.e. pollution. This is a new industrial approach aimed at reducing the consumption of natural resources through their more efficient use, with the objective of preserving the natural environment and at the same time safeguarding the company’s development, and therefore employment.

Thanks to these policies, Ferraro Spa has achieved remarkable results that can be summed up in the introduction of a renewed range of models, which have led to a 47 per cent reduction in overall energy consumption, a 62 per cent reduction in overall steam consumption, and a 37 per cent reduction in overall air consumption, making it an even greater reference in current and future industrial development.

On the sustainability front, Ferraro Spa has adopted new strategic actions, intervening both in the value chain and in relation with supply chain partners. This is a process of high strategic and social value for the company, which focus on green innovation to build the competitiveness of the future. In concrete terms, the company was among the first to join the recyclability project promoted by ACIMIT, to produce textile machinery with 100 per cent recyclable components. While on the innovation front, the focus has been on the digitalisation of all its machinery, with full integration in digital flows, such as Industry 4.0, cloud technology and ‘predictive maintenance’ for remote assistance, where, thanks to the new remote assistance systems, now standard in Ferraro machinery, full remote diagnostics by specialised technicians can be performed directly from Ferraro site, monitoring the status of the machine/ line, identifying and solving any problems or defining the corrective activities to be undertaken. In addition, status checks can be carried out during routine maintenance to prevent breakdowns and ensure the smooth operation of the machinery or even improve its functionality and extend its productivity.

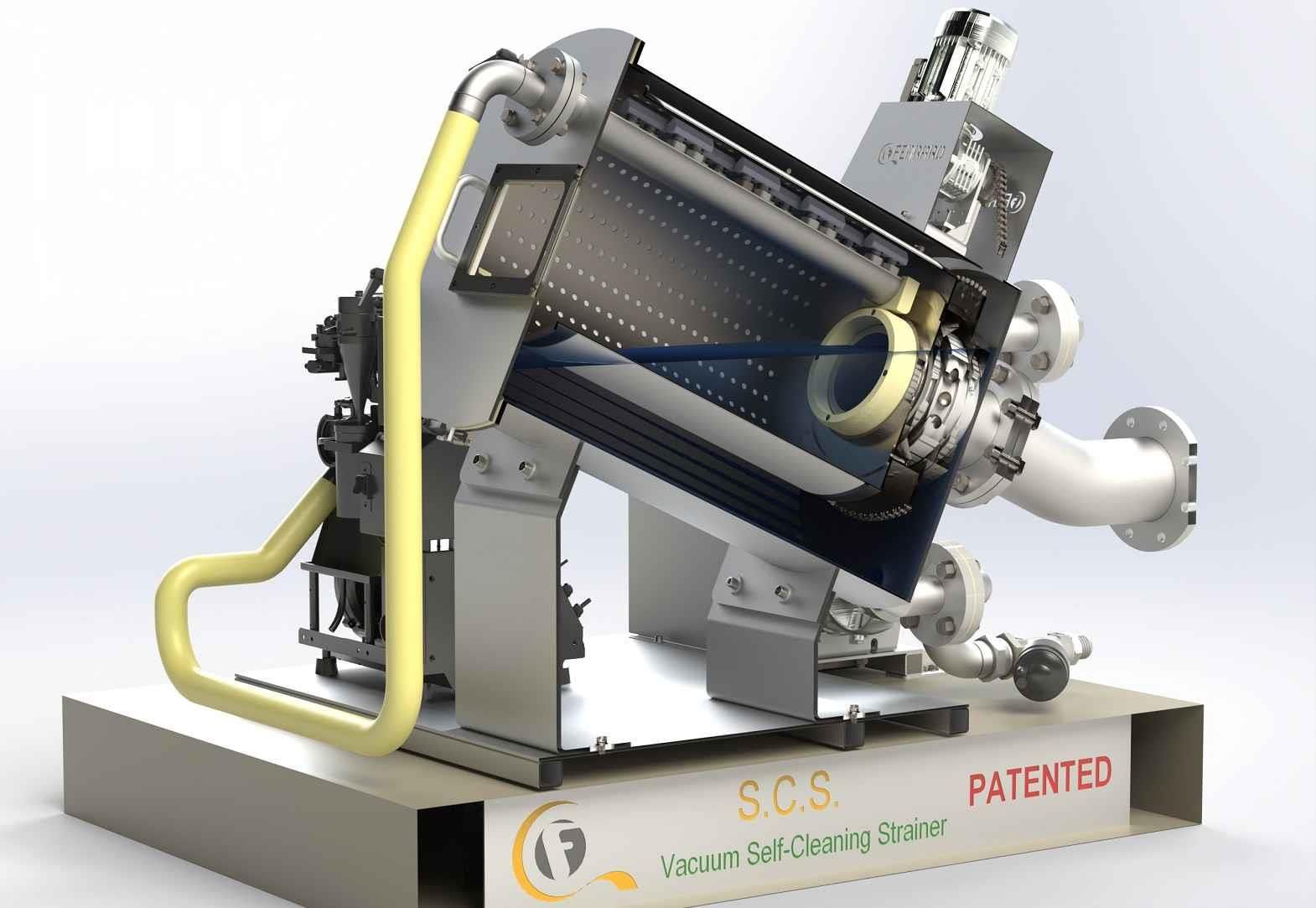

On the product front, Ferraro continues to renew and expand its range. Alongside the novelties presented last year during ITMA in Milan (the new Flexa rubber compactor and the HotFixing tubular heat setting unit), several other novelties are on the way, such as the new version of the Rotoclean oil removal system, completely redesigned and now equipped with a new patented high-performance automatic and self-cleaning filter called S.C.S. This filter is designed specifically for the filtration of chemical batches in the textile industry and is equipped with a vacuum suction system. The superior filtration degree is 35 μm. In the new version of Rotoclean, in addition to the S.C.S. filter, an ultrasonic system is included for the first time, which enables washing and de-oiling efficiency levels at a new level, up till now unseen on the market.

Comments