In today’s rapidly evolving textile industry, ensuring traceability and material integrity has become more critical than ever. Tracer fibre technology offers a groundbreaking solution by providing physical traceability and confirming the integrity of materials throughout the supply chain. This technology allows for the integration of physical data with digital solutions, creating a seamless bridge between the physical and digital realms of textile production. Ensuring precise dosing at a 1:1000 ratio on yarn level is critical for reliable ashing quantification in yarn and fabric. The method currently employed involves cutting filaments to translate RPMs of a rotating blade into dosing volumes, ensuring controlled and accurate dosing. This integration relies on homogeneous tracer fibre dilution, which is essential for maintaining material integrity throughout the process. By ensuring consistency and reliability in dosing, our cutting-edge dosing device, equipped with patented Chopcot® technology, delivers precise quantities of tracer fibre into ginning and spinning processes, further enhancing the effectiveness of the entire traceability ecosystem. With Tracer Fiber and our advanced dosing device, textile manufacturers can confidently navigate the complexities of modern production, secure in the knowledge that their materials are traceable, authentic, and of the highest quality.

To ensure accurate dosing of tracer fibres, constant blending with other fibres is crucial. However, traditional dosing methods like sliver combing proved unstable and logistically unsuitable due to compression and fibre breakage issues. Tailorlux’s patented Chopcot® technology overcomes these challenges by enabling controlled dosing through filaments and rotation cutting, ensuring precise integration of integriTEX® tracer fibres.

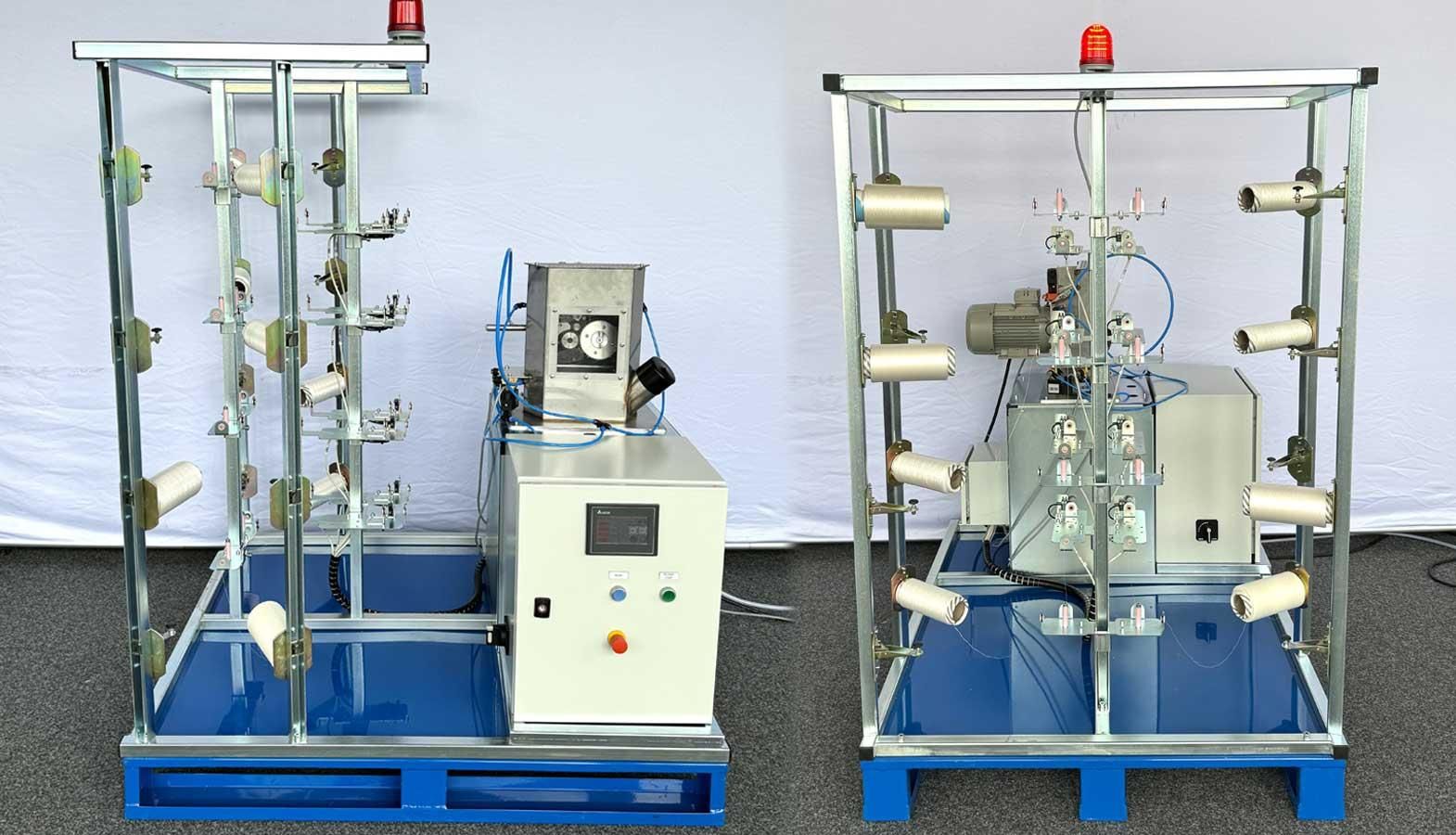

Exact dosing with field proven technology

Every fibre matter and ensuring the exact dosage of tracer fibre is essential for maintaining quality and integrity throughout the supply chain. That is where our patented Chopcot® technology comes in, revolutionising the way tracer fibres are dosed into ginning and spinning processes. This technology creates the entry point for integriTEX® tracer fibres. The unit crimps and cuts filaments to staple fibre, and then doses the fibre into the material flow. Operating at very low material throughput volumes, specifically achieving precise dosing of less than 1 kilo per hour, is crucial for certain applications. The ability to accurately handle such minimal quantities is where the true challenge and value lie.

How it works

The patented technology ensures frictionless cutting by crimping the fibre at the same time. This works at high speed to provide dosing in constant quality. The blades can operate at various speed levels to deliver up to 80 kg per hour. Housing, fan, creel, yarn breakage sensor and control box complete the chopper as a plug & play solution. An IoT box can be added anytime to receive telemetry data on dosing operations.

Technical Data

Key Features

-

Exact dosing of Tracer Fiber

-

Cut & Crimp from Filament to Staple Fibre

-

Yarn Breakage Sensor

-

Plug & Play

-

Patented Technology

-

IoT Integration

-

Corrosion Stability at High Temperatures

The benefits of Chopcot® extend far beyond its innovative design. By ensuring exact dosing of tracer fibres, textile manufacturers can enhance traceability, improve product quality, and meet the growing demands of sustainability-conscious consumers. With Chopcot®, precision dosing is no longer a challenge – it is a guarantee.

This 2nd generation dosing device represents the next evolution of our previous model, delivering enhanced functionality and reliability. We are excited to announce its installation at several customer sites worldwide, showcasing our commitment to innovation and customer satisfaction on a global scale.

Join the revolution in tracer fibre dosing technology. Experience the reliability, efficiency, and precision of Chopcot® today, and elevate your textile traceability to new heights of excellence.

Comments