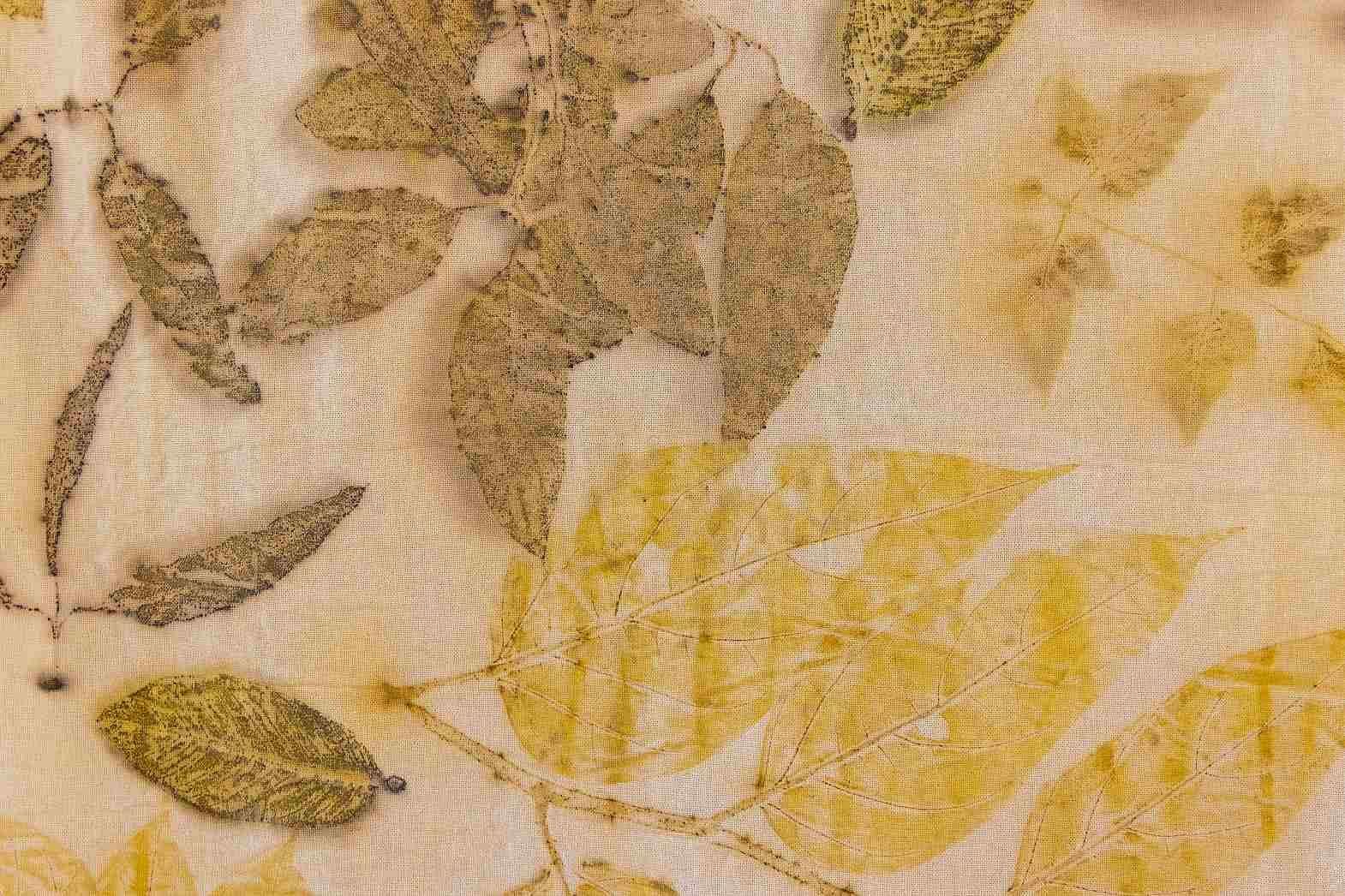

Eco-printing, also known as botanical printing, involves using environmentally friendly techniques to create designs on fabric. It does not necessarily involve using natural dyes for printing. In this technique, organic patterns of various parts of the plants like flowers, leaves, stems, and bark are obtained on the fabric by carefully bundling and binding them onto the mordanted fabric followed by steaming the carefully rolled fabric to finally obtain a beautiful natural texture.

History

The technique of eco-printing is thought to have been originally reported by India Flint, a visual artist from Australia. Flint, who was pregnant with her third child, discovered that the eggs left by Henny Penny, a white Leghorn, in a nest composed of dried eucalyptus leaves had been imprinted with leaf forms after three days of continuous rain. This motivated her to try using this natural method for cloth printing. Although there are few historical records of eco-printing before Flint, she is credited with reviving and popularising the method, releasing her findings in 1999 at the White Nights Textile Symposium in St. Petersburg, Russia1.

Methods of Eco-Printing

Two widely used eco-printing methods include the binding and steaming technique, and the hammering or pounding technique. In the binding and steaming method, different plant parts are enclosed between layers of fabric and then subjected to steam to create prints. On the other hand, in the hammering or pounding technique, plants materials are initially hammered with a soft mallet on top of a layer of fabric before being wrapped and steamed.

Variables of Eco-Printing: Factors Influencing Impressions

The beauty of this technique is that the print obtained is one of its kind and one never quite knows what the outcome will be. Some of the authors also reported improvement in anti-bacterial property of the fabric when it was eco-printed with moringa leaves2.This method has attracted significant attention in recent years because of a growing concern for the environment amidst global warming. Although the process can be conveniently carried out at home and takes only a few hours to complete in batches, it does not always yield a clear impression. In some instances, a pale or no impression has been noted, with various factors potentially influencing the outcome including but not limited to fabric quality, leaf/flower quality, duration of contact between plant material and fabric, type of mordant and weather conditions.

Fabric Quality: The quality of the fabric significantly influences the clarity and vibrancy of eco-prints. Natural fibres often contain impurities such as oils and waxes that hinder the absorption of pigments. Therefore, well-scoured fabrics yield better results. Additionally, the type of fibre—whether protein or cellulosic—responds differently to the eco-printing process, affecting the final impression.

Leaf Quality and Weather Conditions: The quality of the leaves used in eco-printing is crucial, as the pigments in the leaves, which create the impressions, vary based on weather conditions, climate, and freshness. Leaves grown in warm, sunny conditions with cool nights produce more vivid pigments like anthocyanins, resulting in brighter reds, purples, and crimsons. These environmental factors, such as temperature and humidity, can significantly alter the pigments in the leaves and affect the printing process. Seasonal changes can lead to certain flora creating better impressions at specific times of the year. Moreover, the side of the leaf exposed to the sun produces different results than the shaded side, further highlighting the technique’s natural variability. This variability ensures that each eco-print is unique, celebrating the interplay between nature and artistry.

Duration of Contact: The duration of contact between the plant material and the fabric also affects the outcome. While the eco-printing process can be completed in just a few hours, the length of time the leaves remain in contact with the fabric can influence the clarity and intensity of the print. Insufficient contact time may result in pale or incomplete impressions.

Type of Mordant: Mordanting is a crucial step for achieving colourfast results in eco-printing. Various mordants are available, with alum and iron being the most used due to their environmental friendliness. The impressions obtained on fabric treated with these mordants can vary significantly. Iron mordant tends to shift colour to darker shades when printing with leaves, while alum mordant preserves the natural hues of flowers, resulting in lighter, more delicate impressions. This distinction highlights the importance of choosing the appropriate mordant to achieve the desired outcome in eco-printing.

Road Ahead

Eco-printing stands out as an environmentally friendly alternative to the fashion and textile industry, which is under scrutiny for its environmental impact. However, for practitioners who seek consistency of results, the lack of standardised processes and variability in outcomes is a problem. A suitable framework can provide a roadmap for practitioners to achieve consistent, desirable results by systematically addressing key variables such as weather conditions, fabric characteristics, mordant methods, and plant material choice.

Comments