In today’s rapidly evolving industrial landscape, manufacturers face a myriad of challenges that can hinder productivity and efficiency. From supply chain disruptions to labour shortages, rising costs, technological integration, regulatory compliance, and sustainability concerns, the hurdles are significant. However, companies like Staubli are stepping up to provide innovative solutions that help weavers navigate these challenges effectively.

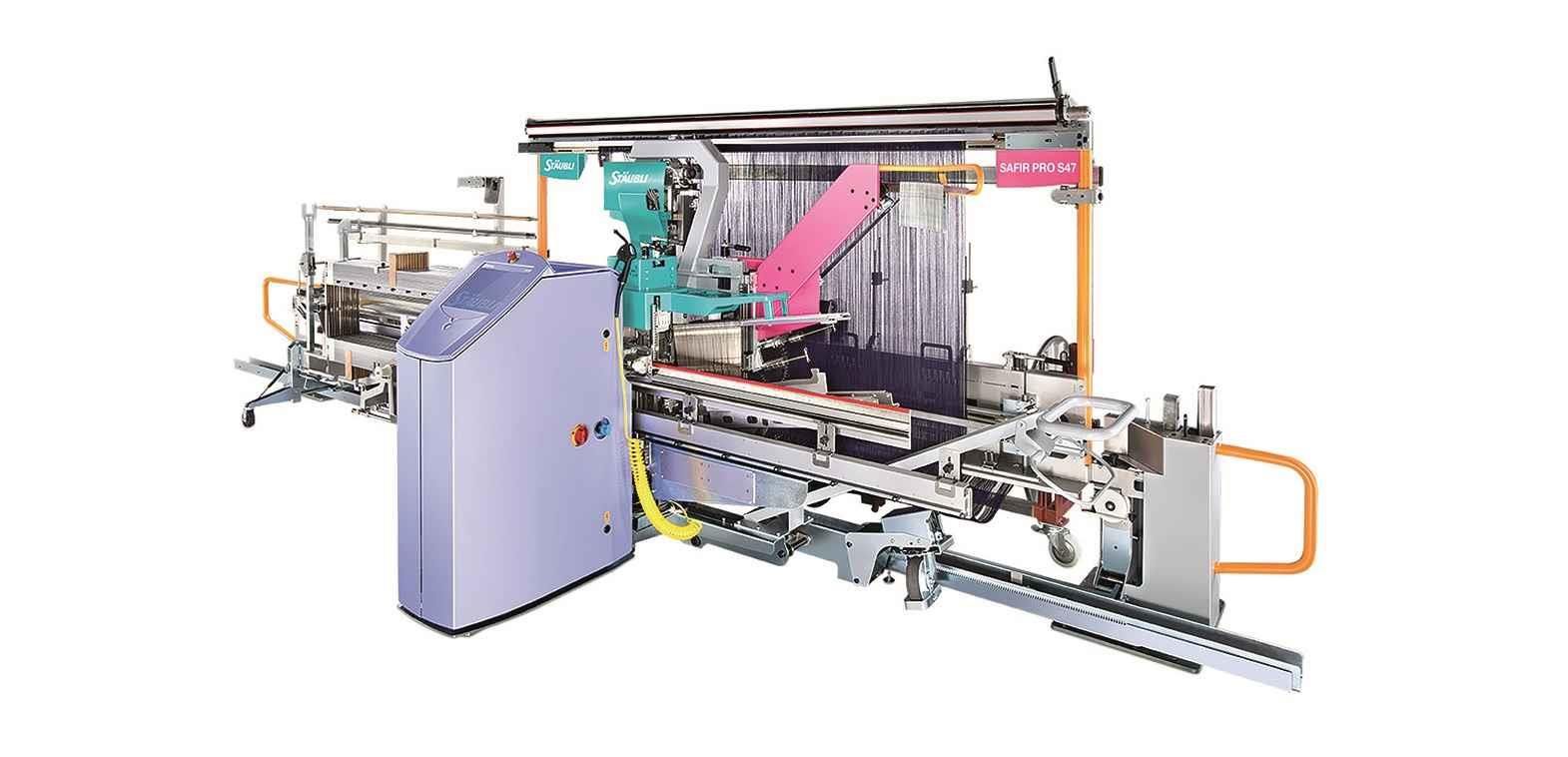

Finding skilled workers is increasingly difficult, with many industries facing a gap due to retiring workers and a lack of new talent. Staubli addresses labour shortages issue through several solutions: for instance, the new SAFIR PRO S47 eases the handling and is designed to enhance efficiency and reduce operational costs.

While automation and digitalisation offer many benefits, integrating these technologies can be complex and involve a steep learning curve. However, our SAFIR automatic drawing-in machine perfectly integrates AWC 2.0 technology for optical, non-contact recognition and measurement of yarn properties. Staubli has set new standards for the automatic drawing in of warps – providing impeccably prepared weaving harnesses. Sophisticated algorithms and cunning software enable fast, error-free, automatic feeds – all supported by smart sensors and optics. Measurements are made when the individual yarn is separated from the warp sheet and ready to be drawn in. Based on the measured data, AWC 2.0 controls the subsequent steps of the drawing-in process. This machine will be launched at ITMA Asia in Shanghai in October.

Inflation and increased costs for raw materials and energy are putting pressure on profit margins. Regarding the rising pressure of energy cost, Staubli LX PRO Jacquard machine, featuring energy savings and reliable data transmission, is a prime example of how technology can support sustainability goals. The LX PRO machine, equipped with Staubli’s exclusive NOEMI electronics architecture and the latest MX PRO module, provides reliable hook selection for weaving various fabrics while minimising energy consumption. This focus on energy efficiency and longevity ensures that weavers can produce high-quality textiles with a reduced environmental footprint.

Global events such as geopolitical tensions and natural disasters can severely impact supply chains, causing delays and shortages. Staubli’s MyStaubli service portal is designed to mitigate these disruptions by providing a centralised platform for equipment management and maintenance. The portal includes an equipment centre that helps staff in weaving mills maintain their machinery efficiently, ensuring minimal downtime and optimal performance. By keeping machinery in top condition, weavers can better manage supply chain uncertainties and maintain consistent production levels.

Keeping up with changing regulations, especially regarding environmental standards, can be challenging. Staubli’s shed formation solutions for frame weaving, such as the new S1551 cam motion for air-jet weaving and the rotary dobby S3018, a comprehensive solution for full range of weft insertion applications (air-jet, water-jet and rapier), are designed with sustainability in mind. These solutions offer robustness, reduced maintenance, and lubricating oil savings, helping weavers meet regulatory requirements while maintaining high-speed, reliable production.

Conclusion

The challenges facing industrial production today are multifaceted and complex. However, with innovative solutions like those offered by Staubli, weavers can navigate these challenges effectively. From the MyStaubli service portal to the SAFIR automatic drawing-in systems, shed formation solutions, and the LX PRO Jacquard machine, Staubli provides a comprehensive suite of tools designed to enhance efficiency, reduce costs, and promote sustainability. By leveraging these advanced technologies, weavers can stay competitive in a rapidly changing industry and continue to produce high-quality textiles that meet the demands of the modern market.

Discover more about Staubli’s extensive package of support during ITMA Asia at the Staubli booth H3D09 and step into the new era of digitalisation and innovation.

20240924091633.png)

Comments