DyStar Singapore Pte Ltd serves as a key hub for the DyStar Group, offering a wide range of innovative dyes, specialty chemicals, and sustainable solutions to customers in the textile and chemical industries. As part of DyStar’s global network, it plays a crucial role in providing expert services and ensuring the highest standards of quality and compliance across the supply chain. DyStar Group’s Global Product Manager of WOPAPAN, Thomas Stepanski, explains how Optidye® N controlled colouration can improve the quality of the goods and reduce process costs.

1. What are the most common challenges faced in the dyeing of synthetic fibres and how can technology help overcome these issues?

1. What are the most common challenges faced in the dyeing of synthetic fibres and how can technology help overcome these issues?

Dyeing synthetic fibres like polyamide presents challenges due to the need for precise control over various factors to achieve high-quality outcomes. Variability in polyamide quality requires a high degree of skill. Conventional dyeing methods often struggle with achieving a high Right-First-Time rate.

Technology helps overcome these challenges by providing individualised dyeing profiles based on fibre analysis (SF and V values) and other parameters, ensuring accurate temperature control, improved combinability of dyes and optimised dyeing processes.

2. How has the integration of software tools in the textile dyeing process improved overall efficiency and accuracy in achieving desired colour outcomes?

The integration of software tools allows for precise control over dyeing parameters, tailored to specific fibre and dye characteristics, which leads to improved levelness, optimised bath exhaustion and more reliable processing. These improvements lead to better batch-to-batch reproducibility and reduced overall process costs.

3. How important is sustainability in the textile dyeing industry and what innovations are being adopted to reduce water, energy consumption and environmental impact?

Sustainability is crucial in the textile dyeing industry, as the process traditionally involves significant water and energy consumption. Innovations such as Cadira® PA in combination with Optidye® N help to reduce the environmental impact. These advancements lead to lower water usage, reduced effluent and decreased energy consumption while ensuring the reliable production of a high-quality article. The lower overall carbon footprint of the dyeing process contributes to a more sustainable dyeing industry.

4. How do modern dyeing techniques and software-driven solutions address the need for batch-to-batch consistency and reproducibility in large-scale textile production?

Modern dyeing techniques, supported by software-driven solutions like Optidye® N, fulfil the requirements for batch-to-batch consistency by providing precise control over dyeing parameters. These solutions ensure that the dyeing process is reproducible by considering critical factors such as fibre characteristics, dye selection, machine parameters and temperature control. This approach minimises variations and ensures consistent quality across large-scale production.

5. How does Optidye® N differ from traditional dyeing methods when it comes to improving the Right-First- Time rate in polyamide dyeing?

Optidye® N improves the Right-First-Time rate by calculating an individual, optimised dyeing profile that considers the specific characteristics of a polyamide fibre, such as the SF and V value. This tailored approach reduces the variability and unpredictability common in traditional methods, leading to higher accuracy in achieving desired outcomes on the first attempt.

6. Can you elaborate on how Optidye® N enhances the levelness and combinability of dyes during the polyamide dyeing process?

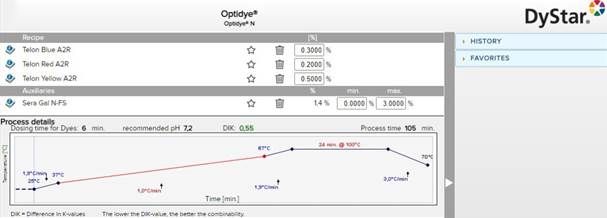

Optidye® N enhances levelness and combinability by generating precise dyeing recommendations based on detailed fibre analysis. By optimising factors such as the pH, the heating rate and the amount of levelling agent, the software ensures that dyes interact more uniformly with the fibre, resulting in more even colouration and better combinability of different dyes. Optidye® N is available for Telon® and Isolan® dyes together with Sera® process auxiliaries.

7. What specific factors should be considered when analysing polyamide fibres?

Before using Optidye® N, it is important to analyse polyamide fibres by determining the SF value, which indicates the quantity of end-amino groups necessary for dye bonding, and the V value, which reflects the fibre’s crystallinity and dye diffusion rate. These factors are essential for accurate dyeing recommendations.

8. How does Optidye® N contribute to a more sustainable dyeing process?

Optidye® N contributes to more sustainability in the dyeing process, because it provides an individual solution which leads to a high-quality article. By working with an individual dyeing process as opposed to working with standard dyeing processes, we can save energy, reduce the effluent loading and achieve a higher Right-First-Time rate. Another important feature of Optidye® N is the fact that it warns the user in case of oversaturation of the fibre and poor combinability. By this, low quality dyeing can be avoided in the first place.

9. Could you explain the significance of the critical temperature range (Tstart – Tend) that Optidye® N calculates, and how it affects dyeing outcomes?

The critical temperature range (Tstart - Tend) calculated by Optidye® N is vital as it dictates the precise temperature at which dyes start to exhaust onto the fibres. Accurate control of this range ensures that dyes penetrate evenly, reducing the risk of uneven dyeing and improving overall colour quality.

10. What are the key advantages of using Optidye® N in terms of batch-to-batch reproducibility and overall dyeing process reliability?

Optidye® N enhances batch-to-batch reproducibility and improves process reliability. By providing individual dyeing profiles tailored to specific fibres and dyes, Optidye® N reduces variability, ensuring that each batch meets the desired specifications with minimal deviations.

11. How does Optidye® N accommodate different machine parameters?

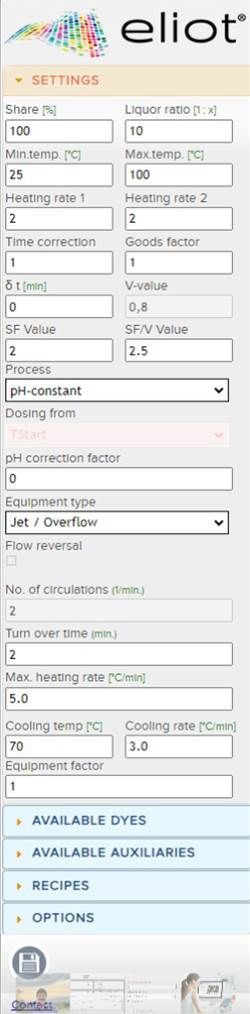

Optidye® N accommodates different machine parameters by allowing users to input specific details such as liquor ratio and machine type (e.g., jet/overflow or yarn/beam). The software then adjusts the dyeing profile to optimise performance based on these variables, ensuring consistent results across different setups.

12. What role do levelling agents play in the dyeing process recommended by Optidye® N, and how does the software determine the optimal amount required?

Levelling agents are critical in achieving uniform dyeing. Optidye® N calculates the optimal amount of levelling agent needed based on the fibre characteristics, total dye concentration, liquor ratio and other machine and process parameters. This ensures that dyes are evenly distributed across the fabric, preventing streaks and uneven colouration.

13. How does the software adapt its recommendations for variations in liquor ratio and why is this flexibility important for dyers?

This flexibility is important as it allows dyers to maintain consistent results regardless of changes in the dyeing setup, ensuring process reliability. Optidye® N adapts its recommendations for variations in liquor ratio by recalculating the necessary amount of levelling agents and adjusting the dyeing pH accordingly.

14. How can interested parties access DyStar’s Optidye® N programme?

Optidye® N is available free of charge for registered users of DyStar’s eliot® platform. Other Optidye programmes such as Optidye PES for polyester and Optidye CR for cotton reactive dyeing, as well as Optidye CI for cotton vat dyeing, are available on the eliot platform, too.

Comments