Leon Theremin is thought to be the first user or inventor of this device as the inevitable part of spy-kit for the Russian Government in 1945. This cannot be a reliable story: the tool invented by Theremin was a passive covert listening device and not an identification tag. The technology applied in RFID has actually been since the early 1920s. The IFF transponder, a much more relevant technology, developed in 1939 and the British utilised it during the Second World War to detect airplanes whether they were friends or foes.

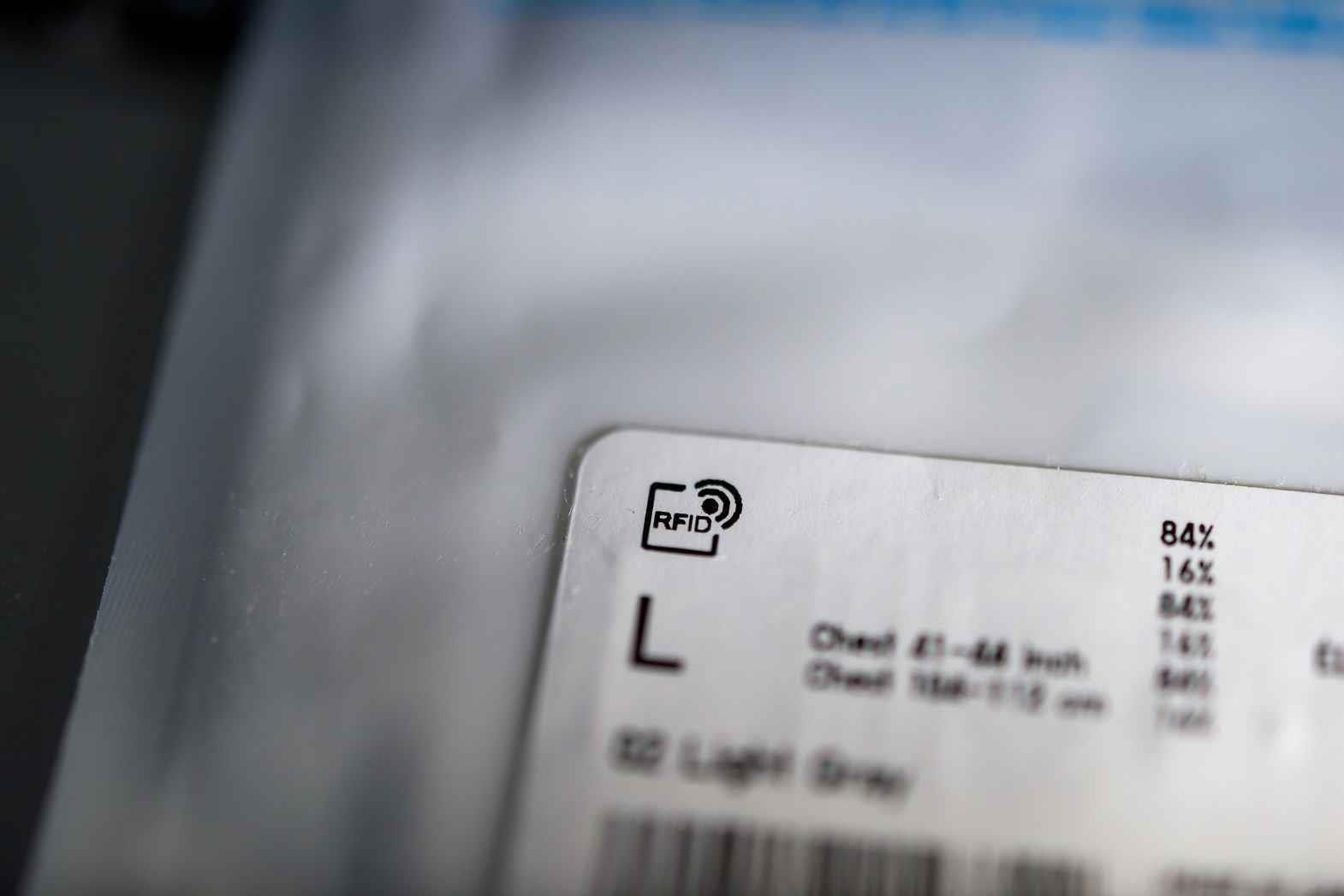

What is RFID?RFID is an all-encompassing expression for technologies that employ radio waves to recognize people or objects automatically. After storing a serial number or other identification data on the chip connected to an antenna, user can use a reader to receive radio waves from the chip and convert the signal into digital information, which can be passed over to computers and be used of.

This technology finds its maximum usage in payment systems, access control and asset tracking. For instance, the logistics industry often uses it in making out large cargos.

RF technology has a widespread use in many areas of electronics and technology such as television, radio, cellular phones, radar and automatic identification systems. RFID (Radio Frequency Identification) provides Automatic Identification of items by using radio frequency signals. RFID is used in various applications like toll collection (electronic), railway car identification and tracking, intermodal container identification, asset identification and tracking, item management for retail, health care and logistics applications national, access control, animal identification, fuel dispensing loyalty programmes, automobile immobilizing and so on.

Radio Frequency (RF) makes mention of electromagnetic waves with a wavelength that fit to use in radio communication. Categorized by their frequencies, radio waves are indicated in kilohertz, megahertz or gigahertz. Radio frequencies range from very low frequency (VLF), which has a range of 10 to 30 kHz, to extremely high frequency (EHF), which has a range of 30 to 300 GHz.

RFID - An OutlineRFID is the fittest and supple technology for automatic operation due to its resilience. It offers benefits not available in other identification technologies. RFID can function under various environmental situations and offers a high quality of data integrity. Moreover, since the technology is hard to simulate, it gives advanced level of security.

Essentially RFID is not different from bar coding. Bar code uses a reader and coded labels that are attached to an item, whereas RFID employs a reader and special RFID tools that are connected to an item. To transmit information from the label to reader, Bar code makes use of optical signals but RFID uses RF signals for the same.

Radio waves communicate between an item to which an RFID device is attached and an RFID reader. The tool can have information of the item, such as what the item is, what time a device takes to travel through a particular area, even a parameter such as temperature. Practically, RFID tools such as a tag or label can be connected to anything - from a vehicle to a pallet of products.

RFID technology uses frequencies within the range of 50 kHz to 2.5 GHz. An RFID system incorporates following parts:

- An RFID tool that accommodates data about an item.

- An antenna used to transfer the RF signals between the reader and the RFID device.

- An RFID transceiver that generates the RF signals.

- A reader that gets RF transmissions from an RFID tool and forward the data to a host system for processing.

Moreover, an RFID system includes application-specific software.

RFID tags have two types: active or passive.

Passive RFID tags are lacking in power supply of their own whereas Active RFID tags are full with power source and may have extensive ranges and sizable memories than passive tags and they have more space to accommodate extra data sent by transceiver. Today, one can find the smallest active tags in the size of a coin.

Passive RFID tags are more in use because their manufacturing cost is cheaper and they are not dependent on battery. Apart from cost advantages, there is nothing special in Passive Tags and exactness and reliability of Active Tags make the use of Active Tags common today. Classified by their radio frequency, there are four types of tags in use viz. low frequency, high frequency, UHF tags and Microwave tags.

Superiority of RFID to Bar CodingAccording to research team, RFID tag has the capacity to store more data including serial number, individual product information and all other information the manufacturers want to insert. Unlike Barcode system, RFID scrutinizes each product individually and does not identify the whole type of product.

RFID technology helps us in spotting any product within a certain distance; we are not required to see the physical existence of product. These plastic-made passive tags are more durable and re-usable.

- Low-frequency RFID tags have a widespread use for animal identification, beer keg and automobile key-and-lock, anti-theft systems.

- High-frequency RFID tags are applied in library book or bookstore tracking, pallet tracking, building access control, airline baggage tracking and apparel item tracking. High-frequency tags are extensively used to identify badges and to replace earlier magnetic stripe cards.

- UHF is normally used in pallet and container tracking in commerce and truck and trailer tracking in shipping yards.

- Microwave RFID tags are used in long-range access control for vehicles.

- RFID transceivers can be used in measuring Seismic sensors, making less complicated remote data collection.

- RFID transponders can be embedded into tyres for tyre tracking; RFID chips are useful in cards as electronic cash.

- This system has a new usage as Smart Key; the key fob contains active RFID circuit that identifies the presence of key within 3 feet of sensor. Consequently driver feels free to open the doors and start the engine even if the key remains in driver's purse or pocket. Invented for animal marking, the embeddable RFID chips are used and brooded over for human beings also.

It is visualized that RFID tags would replace UPC or EAN bar codes because the former has many advantages over the barcode system. However, barcodes have their own plus like lower price than RFID and this quality will keep the barcodes roaming in the market.

Present UPC codes are confined to a single code but RFID codes stand on the opposite end, i.e. they are so long that they have unique code. The matchless qualities of RFID tags denote that a product may be separately tracked as it moves from location to location, eventually arriving in the customers' hands. This system helps organizations in fighting against pilfering and other product losses.

The primary use of RFID in textile rental has, till the date, centered on automating the garment handling process, including check-in, sorting, and checkout. RFID systems in textile rental can eliminate significant manual labor generating typical ROI under two years. Additionally, RFID systems are extremely accurate and generate significant improvements in customer satisfaction.

Benefits of RFID for Textile rental companies- Soiled garment check-in can be conducted inside of the delivery bags saving time and increasing accuracy.

- Clean garments can be automatically or semi-automatically sorted saving significant labor costs.

- RFID enables automated customer premises garment collectors and dispensers allowing for further reduction of end-customer costs and increased textile services margins.

Many Fashion Apparel & Textile companies - particularly those with a large network of stores - are well underway in terms of streamlining their supply chain and optimising sales forecasts and distribution. They are now looking for ways to enhance revenues and market share by adopting modern ways of managing stores and inventory. RFID has now become a centrepiece in their strategic thinking.

The Business CaseBased on gathered information at Management Team level, the typical economic return of an RFID initiative rolled out to a medium-size network (500 stores; 1 distribution centre) takes the following shape:

We can conclude following advantages from several functions of RFID:

This technology is able to compute the total expenditure of commodities in the clumsy situations automatically. Therefore, it diminishes manoeuvring expenses, accelerates the inspecting process, cuts down faults at the cash register, doubles customer satisfaction and reduces pilfering.

With RFID retailers can have an excellent visibility into store operations, which include obtaining back room stock information, stock outs and the locations of inventory in the store. This visibility improves both customer service leads and commodities safety efforts.

Since all the commodities are equipped with the detectors of RFID, retailers are able to have physical confirmation of inventories for number of times everyday or whenever required. Once Inventory counts are created, they can be accomplished within few minutes without any human requirements. Retailers can enjoy the savings of bundle of dollars every year by cutting down physical counts.

Extra security for goods, improvement in the visibility and decrease in the cost of mobile commodities can be offered by RFID tags. They are perfect in sending right commodities to the right place in good time. Effectiveness of Supply Chain not only reduces labour force but also enhances sales.

Items can be labelled and tracked electronically with RFID tags. For instance, asset tracking normally results into better commodity management in stores. RFID has the ability to recognize origins of change and fabrication and can help in removing pilfering.

RFID is not new. The challenge has always been to identify when it is appropriate to apply the technology to your particular supply chain model.

The technology itself offers an opportunity to scan many items simultaneously because it does not need individual line of sight for each item. Thus, a pallet arriving in a warehouse with 10 cases is scanned once, reading all 10 cases simultaneously - including the two in the center of the pallet hidden from the human eye.

Additionally, the ability to store more information on a tag than a bar code enables application of the electronic product code (EPC) to identify items uniquely.

Many opportunities across inventory management, batch management and logistics exist. One opportunity with RFID is automating basic tracking of products. Current manual processes require employees to scan and record data as items move. RFID can help automate this. For instance, if a pallet of yarn has a RFID tag on it and your forklift has a RFID reader aboard; your driver has immediate information of the contents of the pallet when he pulls close enough for the reader to communicate with the tag. Based on that, he knows where that pallet belongs. When it is time to load a knitting machine with yarn, RFID helps locate the pallet stored in the warehouse, wherever it may have been moved, and alerts the driver to its current location.

Another benefit is in the area of batch management and quality assurance. For instance, the possibility of mixing lots of yarn on a knitting machine will be reduced, as you now match a particular lot of yarn with the knitting machine and the production order. The reader on the knitting machine will alert the operator if yarn entering its perimeter is incorrect.

Data carrier and communication device need not to be connected physically. For a common garment retailer is happy to know that instead of walking down each lane in the store or warehouse to check inventory, workers can perform their action from the same premises and accomplish the calculation of inventory in minutes.

Read/write capacities can be conducted within the same assembly line or remotely across continents.

Mobile-tracking tools can be reutilised or disposed, as per the requirement of RFID operation.

In proportion to barcode system, which has 2 to 3 percent failure rate, RFID is able to achieve 100% scanning rate when the item is being scanned for the first time.

Numerous tags can be read at the same time. 'Cluster Reading', as the procedure is known, enhances the data piling process significantly.

RFID improves retailer's ability to scan past all sorts of weather and through other surroundings like metals, bodies of water and dirt. This capacity of RFID easily overshadows barcode scanning which normally fails.

Total expenses of retailer's scanning procedures are reduced by RFID and since RFID can beef up preciseness and data availability, these reduced expenses will turn into savings of time and money.

Finally, the logistics benefit comes from automating the manifest as a container is being loaded. As a roll of fabric passes through the RFID-enabled dock door to the truck, that roll is automatically added to the manifest. If you were to have the truck pass through a second canopy on the way out of the yard, you can again match what's on the truck with the manifest.

Comments