Quality is of prime importance for every industry or business, to get increased sales and better name amongst Consumers and fellow Companies. Generally Quality control standards for export are set strictly, as this business also holds the prestige of the country, whose company is doing the export. As far as Garment quality is concerned, it depends upon the characteristics of the material used. The present paper was aimed at investigating the different technical parameters of the cotton fabric such as cotton crepe, poplin and voile.

Apparatus Used

CRE machine and Elmendorf Tearing strength Tester, Measuring Scale

Testing Procedure

Tensile Strength

This test is used for determining the breaking strength and elongation of most textile fabrics. Here we are taking the reference of ISO 13934-1(Strip test). The Specimen should be 100 ± 1 mm wide and long enough to secure gauge length of 100 mm. Draw a line parallel to long dimension and located 37 ± 1 mm in from the edge of one side of the specimen. Clamp the specimen with the line drawn adjacent to the side of the upper and lower jaws so that the same length of fabric extending beyond the jaw at each end. Distance between clamps - 100 mm. Clamping area of the fabric shall be 25 mm x 25 mm within accuracy of ± 1 mm.And M/c speed - 50 ± 5 mm/min. Effective width of each test specimen shall be 50 ± 0.5 mm after removal of threads equally from both sides and length shall be long enough to allow a gauge length of 200 mm. If elongation at maximum force is more than 75 % then gauge length can be reduced to 100mm. If raveling is not possible than cut fabric of width 50 mm. Then start the test and record the breaking strength of the fabric.

Tearing Strength

This test method determines the tear force required to propagate a single-rip tear of defined length from a cut in the fabric when a sudden force is applied. The force required to continue a slit previously cut in a fabric is determined by measuring the work done in tearing the fabric through a fixed distance. The apparatus consists of a pendulum carrying a clamp which is in alignment with a fixed clamp when the pendulum is in raised, starting position with potential maximum energy... The tear force is computed from scale reading and pendulum capacity. Specimens in warp direction and 5 in weft direction shall be cut. No two test specimen shall contain the same warp and weft threads, and no specimen shall be cut within 150 mm of the edge of the fabric.

Seam Strength

This test method is used to determine the seam maximum force of sewn seams when the force is applied perpendicularly to the seam. The test applies to the standard seam applied to fabric samples or the Production seam as received in finished garments. A measurement of the load required to rupture a seam. Specimen size - Cut sample 100 x 250 mm. Fold the sample in half with the fold parallel to the longer dimension. Make the agreed seam in this direction, and cut to give agreed seam allowance. Gauge length - 100 ± 1 mm.Speed - 50 mm/min Dimensional clamping area of the fabric shall be (25 ± 1mm) x (25 ± 1mm). Condition the specimen till equilibrium is reached.Adjust the distance between the clamps. Place the specimen in the clamp with the seam line centrally located between the clamp faces and perpendicular to the pulling force. Set the m/c speed. Start the m/c and extend the specimen to the point of rupture. Record the maximum force and whether the rupture is caused by

-

Fabric tear;

-

Fabric tear at jaws.

-

Fabric tears at the seam;

-

Breakage of sewing thread;

-

Thread pull out; or any combination of these.

Seam Slippage

This test method is used to determine the resistance to slippage of filling yarns over warp yarns, or warp yarns over filling yarns, using a standard seam. The result is that the yarns pull out but the thread and the stitch doesn't rupture. To assess the seam slippage on the CRE Instrument, it is tested either at fixed seam opening or at fixed load This test method is used to determine the resistance to slippage of filling yarns over warp yarns, or warp yarns over filling yarns, using a standard seam. It is used as an indication of the tendency of yarns to slip at a seam when stress is applied. Sample - cut specimen of size 100 x 400 mm. Fold 110 mm inwards from one end and parallel to the threads of 100 mm side. Stitch at 20 mm from fold line. Cut 12 mm from seam line cutting through both layers of the fabric. Cut 110 mm from seam line so that two specimen are produced, one with seam and one without seam of length 180 mm.Gauge length - 100 ± 1 mmSpeed - 50 ± 5 mm/min .Needle size - 90 metric size Stitches/10 cm - 50 ± 2 ,100 % polyester core spun thread with linear density 45 ± 5 tex .Condition the sample. Set the distance between the clamps and speed of the m/c.Clamp the unseamed portion in the jaws so that the test specimen is mounted centrally. The seam opening force can be recorded from software directly.

Interpretation of Failure of Seam

-

STB: Sewing threads break,

-

FTS: Fabric Tears at Seam,

-

TPO: Treads pull out,

-

FTJ: Fabric Tears at Jaw,

-

FT: Fabric Tears

Results and Discussion:

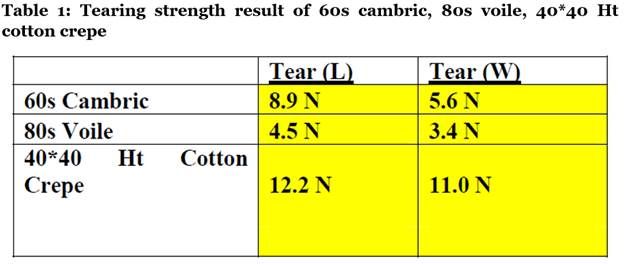

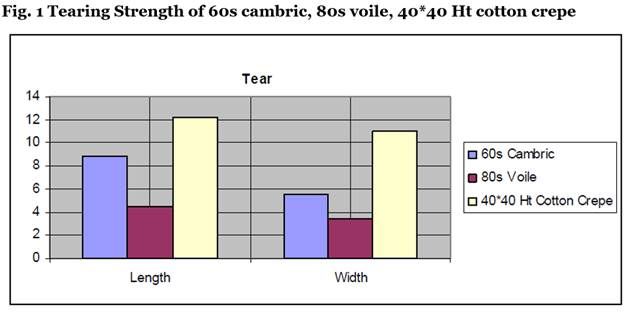

1. Tearing Strength of the different cotton fabric (Fig 1). It is observed that the tearing strength of 60s cambric is greater and 80s voile is having poor tearing strength (Table1).

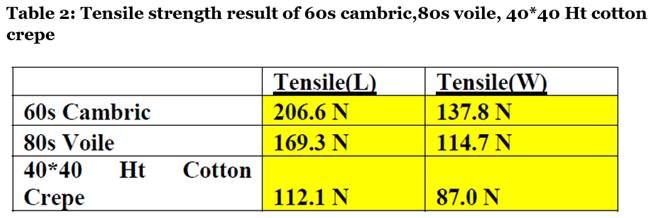

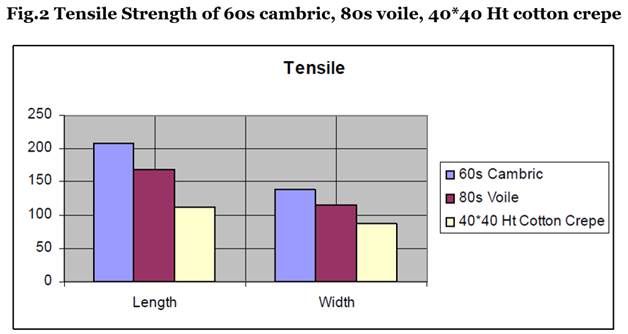

2. In case of tensile Strength also the 60s cambric is having good strength but here 80s voile tensile strength is better than cotton Crepe (Table 2).

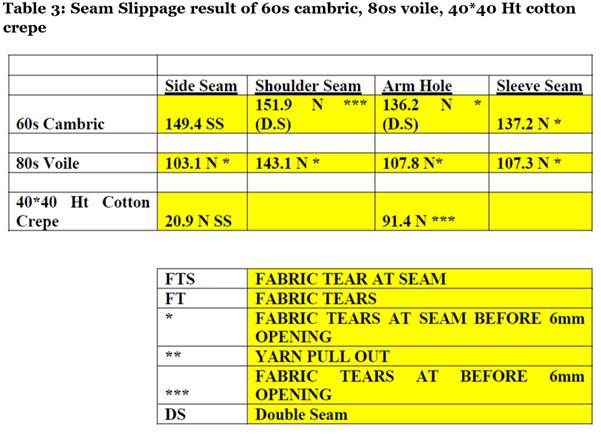

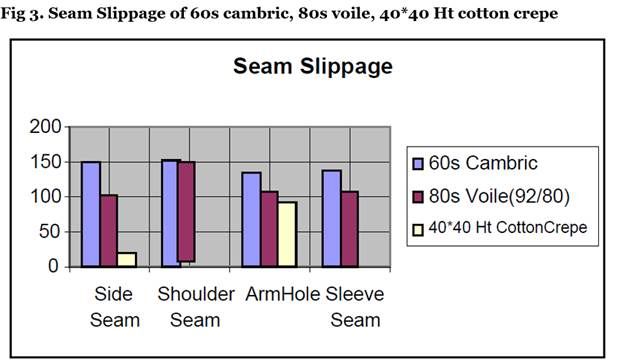

3. In case of Seam Slippage, the test is performed at 6mm opening. And found the 60s cambric (Fig 3) is much better due to its better tensile strength of the fabric and also due to type of stitch used as here we double stitch the garment at shoulder seam and Armhole to assess the effect of type of seam on the Seam Slippage. And same is case with the 80s voile the seam slippage is better either due to better tensile strength and it will be due to number of stitches used as compared to cotton crepe (Table 3).

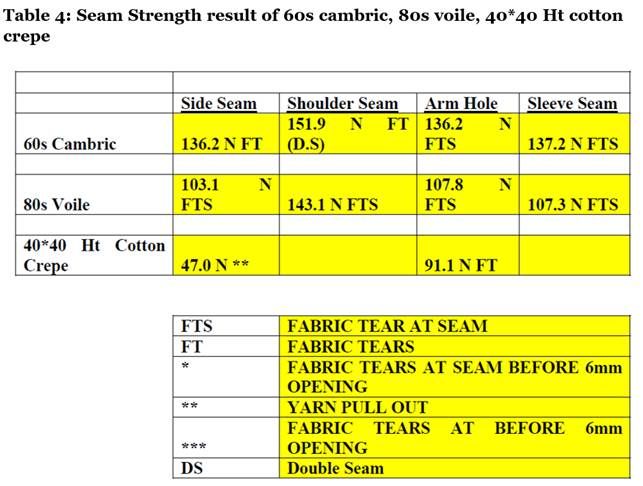

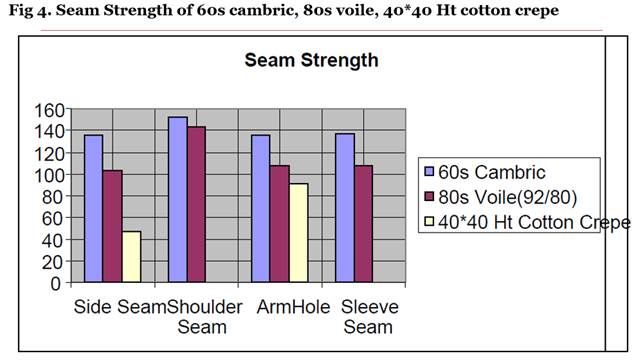

4. In case of Seam Strength also the factors which are affecting the seam slippage same will affect the seam strength of the sample

Conclusion

Here we observe that the tearing strength, tensile, seam Slippage of all the cotton products depend upon the count, type of cotton varites.In case of seam slippage and strength it depend upon the whether we are using double seam or single seam and type of stitch thread and number of stitch thread used. And we can also say that for better Seam slippage and Seam Strength the tensile property will play a important role.

Acknowledgement: First of all, I would like to express profound gratitude to the management of the SGS India Private LTD., Gurgaon and our Lab Manager Mr. Rahul Garg for giving encouragement and guidance to work on Technical Parameters of Cotton fabric of Garments.

Comments