Garment manufacturing is the technology of converting 2-dimensional fabric into 3 dimensional fabric. The garment industry has become a high-profile industry with lots of emphasis on the properties of garments. The properties of garments during wear are related to the type of fabrics used, the stitches employed and also the types of threads use. This paper reviews the Seam strength and Seam slippage of fabrics. Different types of stitches and different types of sewing threads and their affect on the above-mentioned properties have also been reviewed SEAMS.

What are seams?

It is necessary to define the term seam at an early stage in any discussions because its application is boarder than is generally realized. In common parlance, a seam is join between two pieces of fabric. Indeed, this was the assence of the British Standard definitions of seams as contained in the 1965 version of BS 3870: schedule of stitches, seams and stitching's. The noun “Stitching” then apply to situation where there is only one piece of fabric, such as when fabric edges are neatened or hems created, and where decorative sewing is involved.

The current BS 3870: Part 2: 1991: Classification and Terminology of seam types and the earlier 1983 edition, define a seam as “the application of series of stitches or stitch type to one or several thickness of material”. Thus the term includes virtually all sewing that goes into the garment. Perhaps in the future, the further development of non-sewing methods seaming will cause this definition to be altered, but the current definition is appropriate to present the purposes.

Seam quality defects and remedies.

Seam Failure - Seam Slippage

Description:

Where the yarns in the fabric pull out of the seam from the edge. This often occurs on fabrics constructed of continuous filament yarns that are very smooth and have a slick surface. Also caused by loosely constructed fabrics.

Minimizing seam failures – seam slippage:

1. Consider changing the seam construction to a French seam construction.

2. Increase the seam width or width of bite.

3. Optimize the stitches per inch.

4. Contact your fabric supplier.

Seam properties.

Seam Strength:

A measurement of the load required to rupture a seam. Wovens are tested using “jaws" method and knits are tested using a "ball-burst" test method.

The five major contributors to seam strength include:-

1. Fabric type and weight.

2. Thread type and size.

3. Stitch and seam construction.

4. Stitches per inch.

5. Stitch balance.

Any one of these factors can adversely affect the performance of a sewn product depending on the end-use of the sewn product.

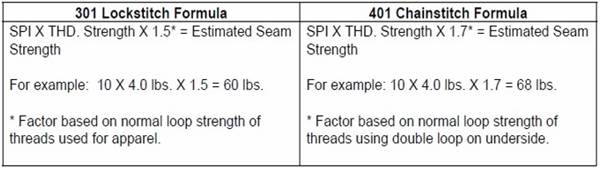

Estimating Seam Strength on Woven’s: -

Below are two formulas that were developed for estimating the seam strength on woven fabrics. To do the calculations, you need to know the following:

• Stitch type (301 Lockstitch or 401 Chainstitch)

• Thread Strength (Single-end breaking strength of the thread, measured in pounds)

• Stitches per inch

Seam Slippage: -

Seam slippage is to test whether the yarn across the woven fabric does not come out from the seam of a garment when a force is applied on them. It is also used when a breaking force of rupture, a minimum elongation, or both are required to determine the sewn seam slippage, or seam integrity of a fabric for a specified end use. Seam slippage occurs when the density of the fabrics or the construction is low, less warp and weft per inch.

Stitches.

What are stitches?

British Standard 3870: Part 1: 1991: Classification and terminology of Stitch Types, is the standard reference to the wide range of stitch types now available for use in garment construction. It defines a stitch as: “one unit of confirmation resulting from one or more strands or loops of thread intralooping, interloping or passing into or though material”.

Intralooping is passing of loop of thread through another loop formed by the same thread. Interlooping is the passing of loop of thread through another loop formed by different thread. Interlacing a term also used in relation to certain stitches is the passing of the thread over or around another thread or loop of another thread. A series of recurring stitches of one configuration is defined as a stitch type. BS 3870: divides many types which are available into 6 classes which variously covers the demands of joining fabrics together, neatening raw edges, or providing decorations, or offer the economy of doing more then one of these at a time.

Sewing thread. Thread construction: -

Air Entangled Thread

Is made from continuous filaments of polyester that are entangled as they pass through a high-pressure air jet. This yarn is then twisted, dyed, and wound on cones with lubricant. Air entangled threads are used in everything from seaming flags to heavy denim jeans. (Example products are Magic, Signature Plus, and Signature Machine Embroidery™.)

Core Thread

Is made by spinning a wrap of staple cotton or polyester around a continuous filament of polyester fibers. Afterwards, two or more of these single yarns are twisted together to form the thread. Core threads have fuzz on their surface giving them good lubricity characteristics and also a continuous filament core that contributes to high strength and durability. When wrapped with a cotton wrap, core threads have very good needle heat resistance. When wrapped with a polyester wrap, core threads have excellent chemical resistance and colorfastness. Core threads are used in everything from fine blouses to heavy coveralls and overalls. (Example products are D-Core and PermaCore.)

Monocord Thread

Is produced from continuous filaments of nylon that have been bonded together. They have very little twist so that they look like a single cord of yarn. Because of the way these threads are made, they appear to be flat and ribbon-like, which provides a high degree of resistance to abrasion. Monocord threads are exceptionally strong for their size so they are used in the manufacturing of furniture, shoes, and other heavy duty applications. (Example products are Anecord, Anequilt, and TerylB.)

Monofilament Thread

Normally produced from a single nylon continuous filament resembling fishing line. Usually monofilament threads are used because the thread is translucent and blends in with many colors. Because it has a tendency to be stiffer than other filament products, it is not recommended for seams that may lay adjacent to the skin. Also, because it is a single filament, it may unravel easily if the thread is not locked in the seam adequately. Monofilament threads have been used in quilting operations on quilts and bedspreads, as well as, in blindstitch operations on drapery and apparel. (Example product is Clearlon.)

Spun Thread

Is made from cotton or polyester staple fibers that are spun into single yarns and then two or more of these yarns are plied to make a sewing thread. Spun threads have fuzz on their surfacing giving them a soft hand and good lubricity characteristics. Spun threads are used in everything from women's lingerie to heavy leather gloves. (Example products are: Anecot, Anecot Plus, DuPont™ Kevlar, DuPont™ Nomex, Endurance™, Excel™, Spun Kool, and Perma Spun.

Textured Thread

Is made from continuous filaments of polyester or nylon that have been textured by pin, disc, or belt and then heat set to insure proper bulk retention. Textured polyester is usually manufactured with regular or mid tenacity, continuous filaments depending on the application. Textured threads are ideal for overedge, chainstitch, and coverstitch of the finished seam and offers good seam elasticity. Textured threads are usually less expensive when compared to other thread types. (Example products are: Best Stretch, Tex Kool, and Wildcat Plus.)

Twisted Multifilament Thread

Is made from continuous filaments of polyester or nylon that are twisted together into a cohesive bundle and then plied to make the thread. They are then dyed, stretched, and heat set to achieve the desired physical characteristics. Twisted Multifilament threads are available either soft or with an additional bond for better ply security and abrasion resistance. They are exceptionally strong for their size and they have excellent resistance and durability. These threads are used for seaming everything from bathing suits to automobile upholstery. (Example products are: Anefil Nylon, Anefil Poly, Anefil Stx, Cocoon Performance Bobbin.)

Twisting

The above types of thread constructions that involve twisting (such as spun, core, and twisted multifilament) are twisted in the following directions:

"S" direction or right twist for single strand yarn (such as spun)

"Z" direction or left twist for ply yarn (such as core and twisted multifilament)

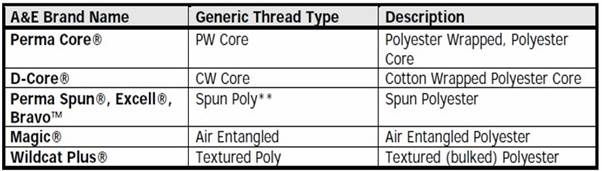

3.2. Thread brand legend: -

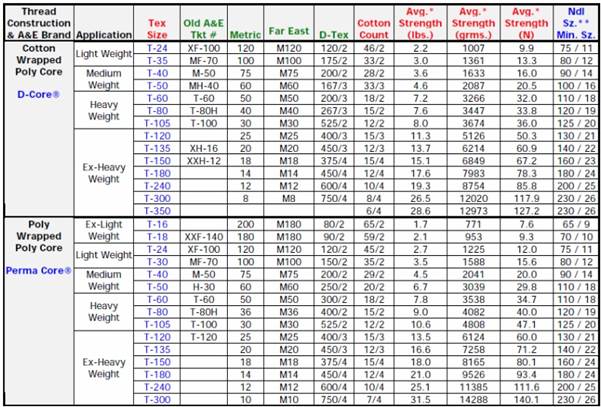

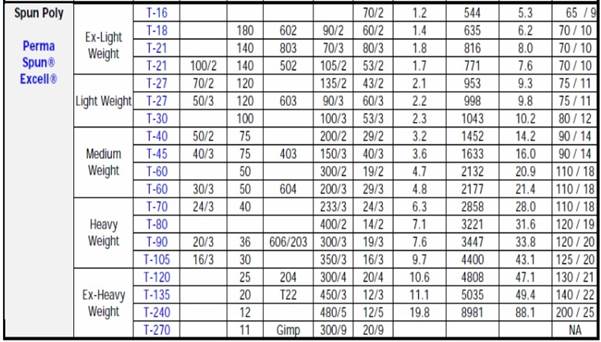

2.3.3. Thread Size Comparison:-

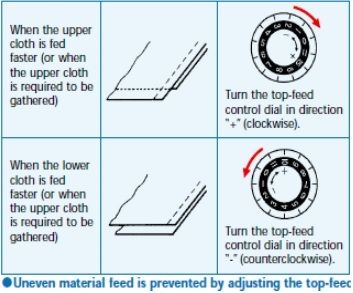

The top-feed dog has been designed so that the operator can smoothly place the material to be sewn on it. Furthermore, the gauge can be easily replaced and stitch adjustment can be performed without difficulty. The machine comes with a forced lifting mechanism for the top-feed dog. This enables the operator to place the material to be sewn on the top-feed dog more smoothly. The machine incorporates its exclusive chain-off thread presser pedal foot, which improves seam quality and ease of operation. The exclusive gauge comes in five different types, and the gauges can be replaced in a simple procedure. This facilitates the required adjustment when changing the needle count. The machine is also capable of performing partial shirring. The machine works effectively for processes which require partial shirring as long as the partial shirring device (PH-3) is used in combination with the partial shirring dial. The partial shirring device comes in two different types, the kneepad drive type and the pedal drive type. The machine comes with many different, functions to prevent uneven material feed and puckering for higher-quality seams. The machine incorporates many functions and places a great deal of importance on higher product quality. The machine is adaptable to a wider variety of light-to heavy-weight materials and takes full advantage of top-feed mechanism. This enables unskilled operators to finish seams of consistent quality.

Summary:

Thus the importance of Seam strength and Seam slippage of fabrics has been clearly studied for the garment manufacturing process. A thorough knowledge of different types of stitches and different types of sewing threads and their affect on the above-mentioned properties is required for the garment manufacturing process.

Comments