The use of nanotechnology in the textile industry has been very useful to man. It has been applied in various industries like engineering, medicine, information and communication, aerospace, automotive, construction, etc.

Nanotechnology came into existence around 2600 BC in China when people started dyeing fabrics, and since then, it has been unknowingly used to impart different colors, shapes, and strength to fibers and fabrics. People started understanding that nanoparticles and nanofibers have exclusive properties which can be used to add different properties to fabrics. Properties like mechanical strength, chemical resistance, water repellence, antibacterial properties, etc. were unattainable by any other means.

Nanotechnology has gained popularity in the last 15 years, and the textile industry has benefited greatly from it. Manufacturing textiles with the help of nanotechnology is a complex process, but its results are effective and long-lasting.

To get a better understanding of nanotechnology in the textile industry, it can be bifurcated into three major categories:

Fabrication of nanofibers

Surface modification of fibers and fabrics

Nanoparticle composite fibers

Fabrication of Nanofibres

Surface Modification

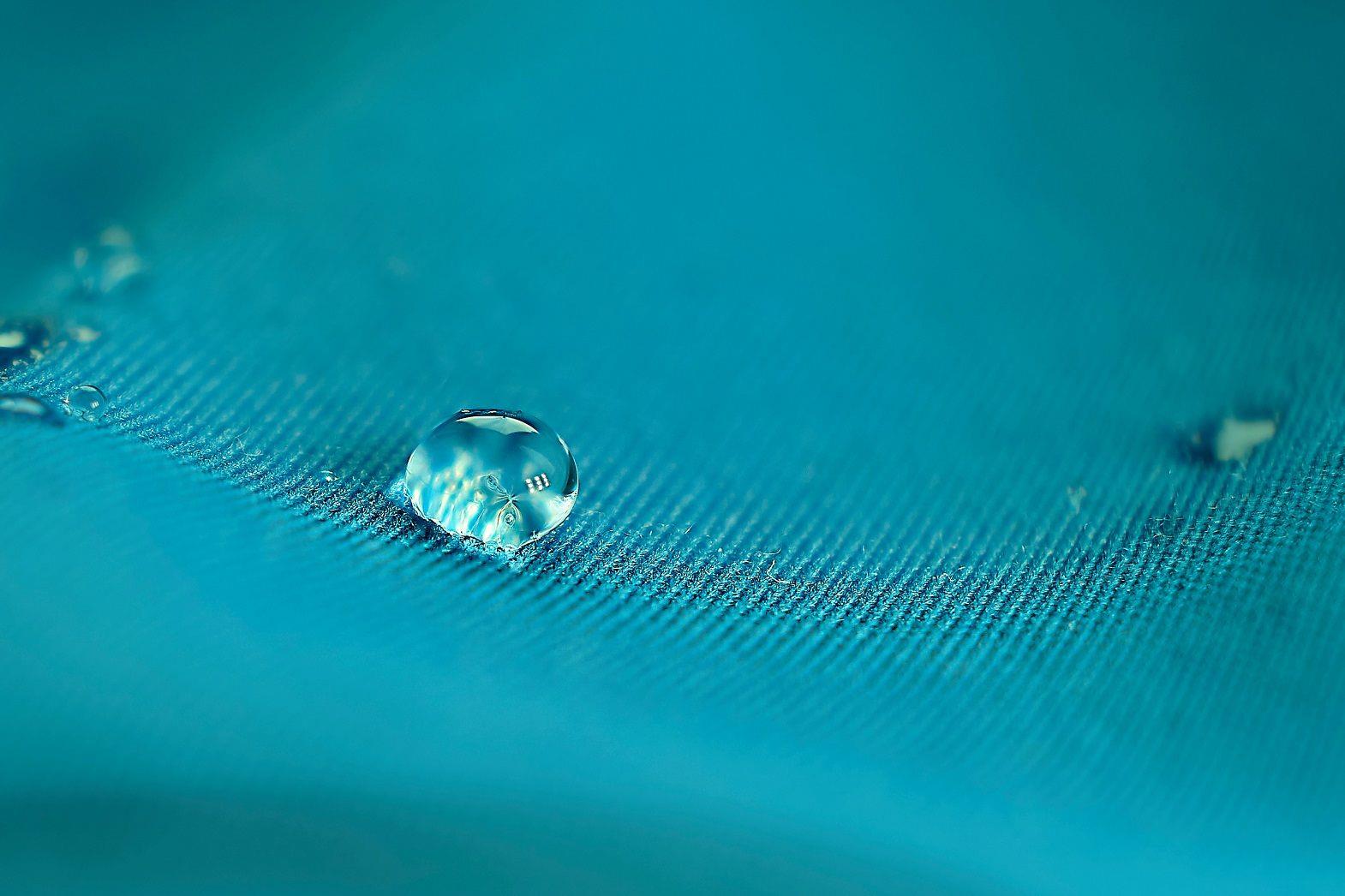

Out of the three categories, surface modification is the best established technique and has plenty of applications such as water and stain repellency, wrinkle resistance and flame retardation. Electro-textiles, chemical/biological detection and microbe resistance are some if it's advanced applications. Effects of these applications usually depend on various properties like charge of the particle, size, and surface chemistry. But nonetheless, all these applications have beneficial properties. This application is also used in swimsuits. A cold plasma technology is used to make the fabric water repellant.

Surface modification techniques have proved very beneficial in manufacturing. But it faces a longevity issue. Washing, wear and tear, etc deplete its coatings on a fabric making it loose its unique properties.

Nanoparticle Composite Fibers

Nanoparticle composite fibers are commercially used the least. Incorporation of nanoparticles can be used to create anti microbial and electrically conducive fibers.

With the help of this technology, tiny carbon particles can be integrated in a fabric. This protects the wearer from electrostatic charge that comes from a fabric. Along with this, fabrics manufactured with this technology are stain resistant, water repellant and wrinkle free. They can be washed at lower temperatures and at lesser frequency.

Nano-Textile Products

Nanotechnology techniques are used in many industries. Various kinds of fabrics and goods are manufactured with nanotechnology applications. These products range from personal goods to sports fabrics with improved mechanical properties, odor reducing, and antibacterial properties and military textiles such as flexible body armour and camouflage. Medical textiles like antimicrobial wound dressing, bedding and clothing is also manufactured through this technique.

Nanomaterials Used in Textiles

Nanomaterials improve the performance and add unique properties to fabrics. Whether it's a natural fabric or a synthetic one, different nanomaterials are used in textile manufacturing because of the properties they impart. A variety of nanoparticles and nanotubes which are used in textile manufacturing are as follows:

|

Nanomaterial |

Properties |

|

Carbon black nanoparticle/nanofibres |

Abrasion resistance, Higher tensile strength, Good chemical resistance, electrical conducting |

|

Carbon nanotubes |

Exceptionally strong, lightweight, electrically conducting, thermally conducting |

|

Metal oxide nanoparticles |

Photocatalytic, electrically conductive, UV protection, antimicrobial |

|

Metal nanoparticles |

Antimicrobial, solar cells, aesthetic properties |

|

Clay nanoparticles |

Electrical resistance, fire retardant, UV shielding. |

(www.azonano.com)

Nanotechnology is still an evolving field. Even though it has strong grounds in manufacturing various kinds of products, it will continue to develop in the future. Researchers have been working to improve this technology and its applications. This technology is much in demand because of its ability to carry out tasks efficiently and impart unique and valuable properties to fabrics.

References:

1. Slideshare.net

2. Lifesciencesweek.ch

3. Textileworld.com

4. Azonano.com

5. Science.howstuffworks.com

Comments