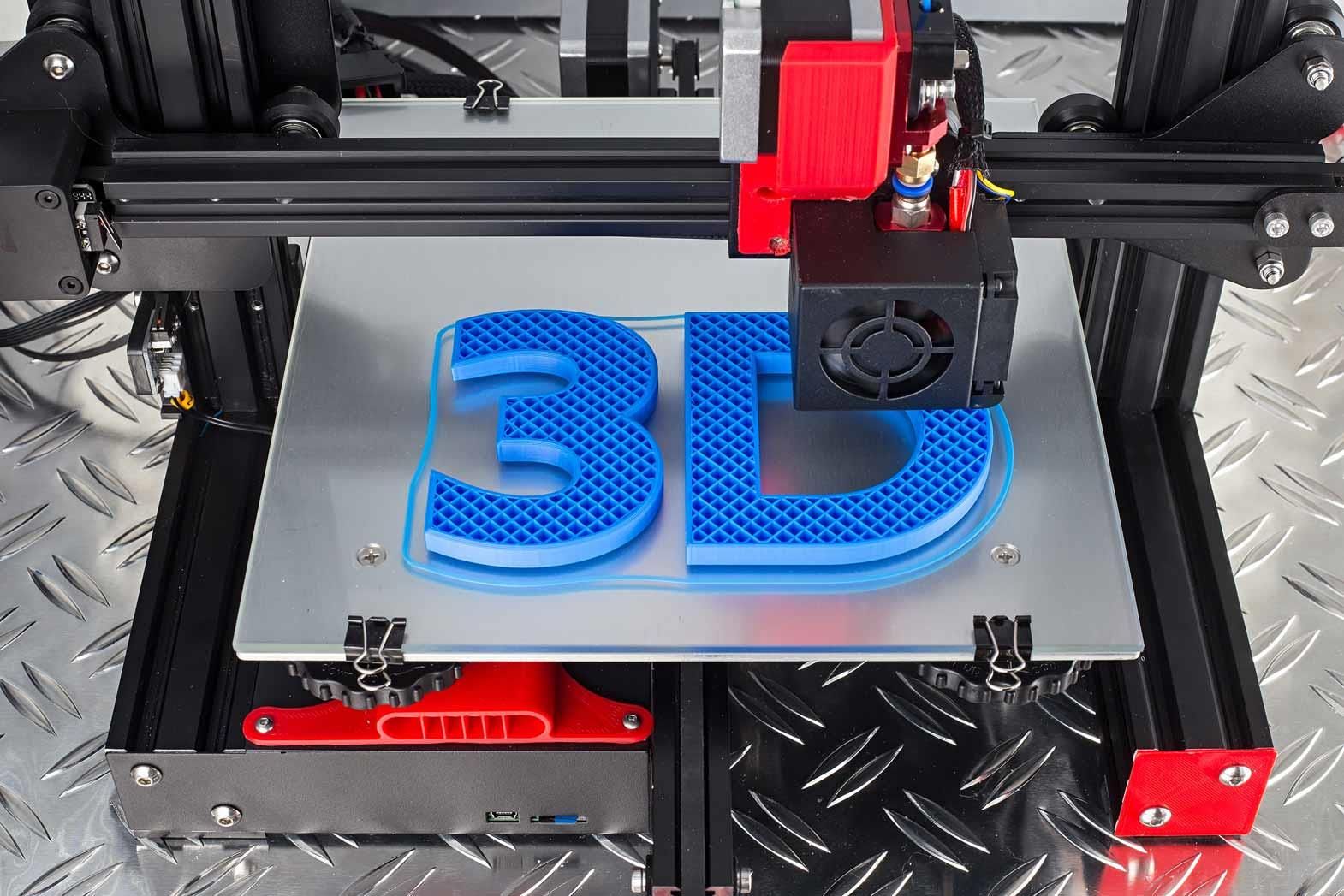

3D printing is also morecommonly referred to as Additive manufacturing (AM). It is a process of making three-dimensional material of any shape and size via a digital program. Layer after layer are laid down to form different shapes using an additive process.This process has been in the market since the beginning of the 20thcentury hence the prices of 3D printing machines have dropped substantially.

The models for 3D printing are usually developed through traditional design programs like AutoCAD, Rhino, SolidWorks, etc, by trained professionals.Engineers, product designers, and architects create the digital, geometric representations of products using various design programs. These representations are made in virtual 3D. This data is then converted into an industry standard file format know as .STL (Stereolithography).

The data is then captured in the form of numerous 2D slices and sent to AM machines for manufacturing. In this machine, the product is built in layer by layer and the final product is completed in just a couple of hours. The product is made via a 2D cross section. There is also a provision of adding new layers to the already manufactured product. These layers can be added in various ways giving different properties to the product. Different printing technologies, processes and methods have different properties and strengths.

This process was developed in the 1980's. The reason for developing these technologies and processes were the laws introduced during that time. The laws aimed at improving the environment by restricting the amount of harmful compounds released into the atmosphere by other manufacturing processes,products and ingredients like printing inks, packaging materials, etc.

3Dprinting provides a lot of advantages over traditional manufacturing. This is the reason it has been adopted by various high profile companies. This process is gaining plenty of popularity and is spreading like fire in the market. It has many benefits.

The cost of manufacturing is relatively less in 3D printing. It involves lesser work force and cheaper and more reliable raw materials. Also, it reduces the shipping and packaging costs. Through this technology, it is also possible to print your own objects. It is not very cost efficient to do so currently but itis gaining popularity and with the advancement of Additive Manufacturing techniques, it is likely to get cheaper.

The most obvious result of cheap manufacturing is quick production. If you compare 3D printing with traditional manufacturing, the former is clearly a time saving option. The end result of both the methods is the same. But 3D printing takes just a couple of hours to complete the desired product, whereas traditional manufacturing methods can easily take several days or even weeks to manufacture the same product. 3D printing is both time and cost saving.

Another advantage of 3D printing is that it produces less waste. Fabricating plastic and metal objects particularly releases a lot of waste and surplus material. 90% of the raw material used during making aircrafts goes to waste. 3D printing consumes less energy and at the same time reduces wastage of raw material. The finished product through 3D printing can be 60% lighter than the product manufactured through traditional methods.

Needless to say if 3D printing takes less time, reduces cost of manufacturing and reduces wastage of raw material, it provides better quality as well. Mass manufacturing faults can be avoided by layer by layer manufacturing. Because of 3D printing, the products look better, work better and last longer.

With 3D traditional manufacturing technique, it was very difficult to experiment with different shapes and sizes because it was time consuming and involved using a lot of raw materials. But since everything is done digitally in a 3D printing process, the possibilities are unlimited. One can use their imagination and create infinite number of figures, simple or complex. Also, experimenting with different types of materials can also be done via 3D printing which was earlier not possible because of different chemical and physical properties of raw materials and cost incurred to infuse to them through traditional methods.

3D printing may seem a little outside the box but it has its benefits. It is similar to clicking a photograph from a digital camera and knowing what exactly the end result would look like. Because of this technology, one does not need to invest large sums of money set up a factory to test a product. One can easily try one or two samples in a 3D printer to see if their product comes out the way it was imagined or if it's worth mass-manufacturing. Engineers and designers have been using this technology for a very long time but majorly to create prototypes. But with its increasing popularity, usefulness and effectiveness it wont be long before manufacturers starting using 3D to create final products as well.

References:

1. Digitalforming.com

2. Economist.com

3. Augmentedtomorrow.com

4. Zcorp.com

5. Wikipedia.com

Comments