Nanotechnology is a growing interdisciplinary technology often seen as a new industrial revolution. Nanotechnology (NT) deals with materials 1 to 100 nm in length. The fundamentals of nanotechnology lie in the fact that the properties of materials drastically change when their dimensions are reduced to the nanometer scale. Nowadays, the textile industry has also discovered the possibilities of nanotechnology. So, we can define nanotechnology in textile as the understanding, manipulation, and control of matter at the above-stated length, such that the physical, chemical, and biological properties of the materials (individual atoms, molecules, and bulk matter) can be engineered, synthesized, and altered to develop the next generation of improved materials, devices, structures, and systems. It is used to develop desired textile characteristics, such as high tensile strength, unique surface structure, soft hand, durability, water repellency, fire retardancy, antimicrobial properties, and the like.

Modern Application of Nanotechnology in Textile Industry:

Nanotechnology is increasingly attracting worldwide attention because it is widely perceived as offering huge potential in a wide range of end uses. The unique and new properties of nanomaterials have attracted not only scientists and researchers but also businesses, due to their huge economical potential.

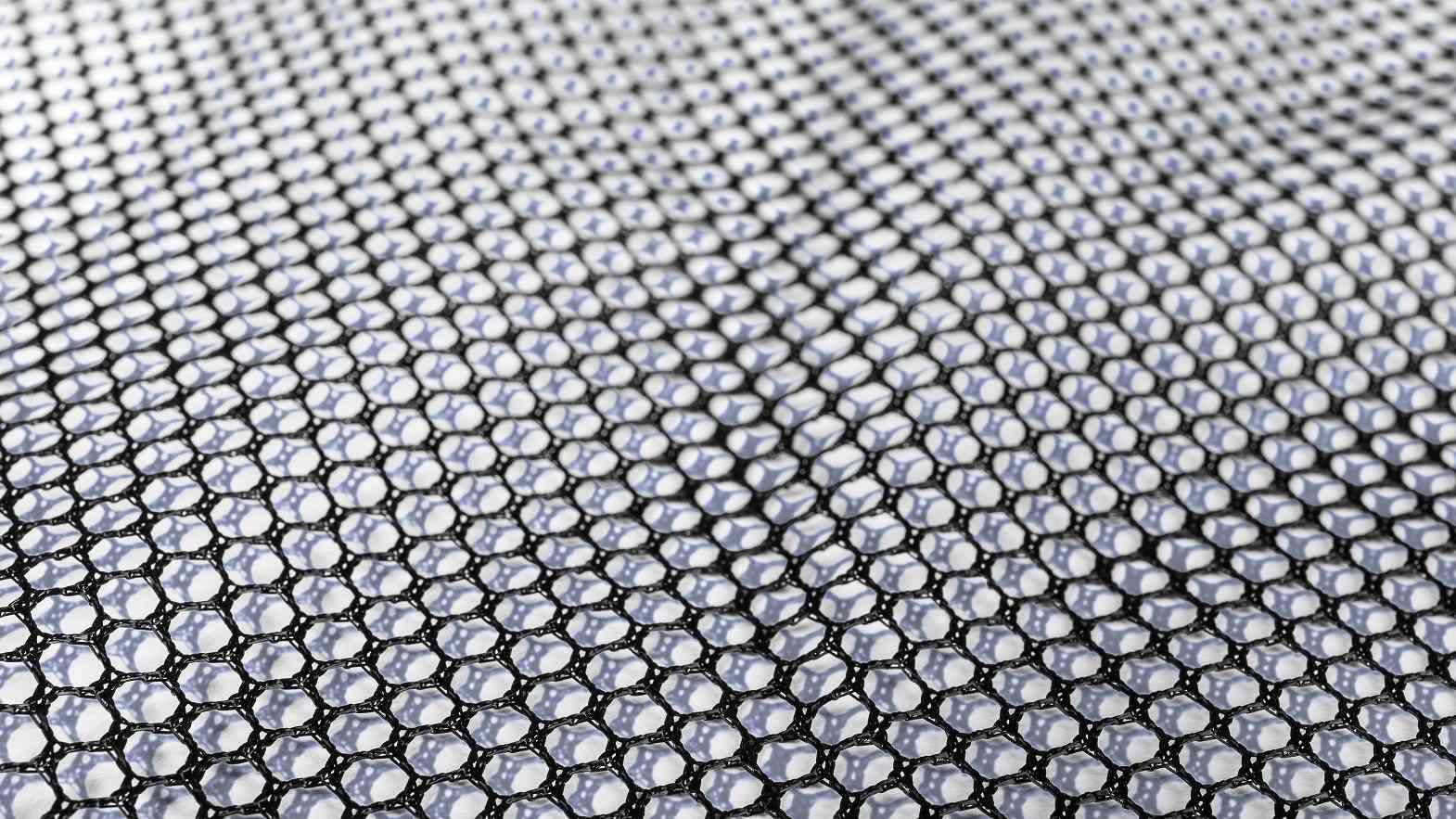

Nanotechnology also has real commercial potential for the textile industry. This is mainly due to the fact that conventional methods used to impart different properties to fabrics often do not lead to permanent effects and will lose their functions after laundering or wearing. Nanotechnology can provide high durability for fabrics because nanoparticles have a large surface area-to-volume ratio and high surface energy, thus presenting better affinity for fabrics and leading to an increase in the durability of the function. In addition, a coating of nanoparticles on fabrics will not affect their breathability or hand feel.

Application of Nanotechnology can be explained in three ways:

Application in department wise.

Application in properties of textile material.

Application in the apparel industry.

This type of application includes Nanotechnology in manufacturing composite fiber And Nanotechnology in textile finishing

Nanotechnology in manufacturing composite fibers include the following topics

- Carbon nano fibers and carbon nano particles

- Clay Nano particles

- Metal Oxide Nano particles

- Carbon nano tubes

- Nano cellular foam structures

Nanotechnology in textile finishing includes

- Upgrade of chemical finishes and resultant functions

- Nano particles in finishing

- Self-assembled nano layer

Application in apparel industry:

Examples of industries where nanotech-enhanced textiles are already seeing some application include the sporting industry, skincare, space technology and clothing and material technologies for better protection in extreme environments. Treating textiles with nanotechnology materials is a method to improve the properties of the textile, making it longer durable, have nicer colours etc. Nanotechnology can also be used to add new functionalities like energy storage and communications. Some interesting examples of nano improved textiles currently on the market are:

- Stain repellent and wrinkle-resistant threads woven in textiles

- Body warmers use Phase Change Materials (PCMs) responding to changing body temperatures

- Nano socks treated with silver nano particles. The silver acts against infection and odor.

Swimming Suit:

The most widely recognized application t is in the shark-skin suit worn during world-record breaking Olympic swimming championship. The suit, which includes a plasma layer enhanced by nanotechnology to repel water molecules, is designed to help the swimmer glide through the water and has become a common feature of major swimming events as all competitors attempt to enhance their chances of winning.

Sporting Goods:

Running shoes, tennis racquets, golf balls, skin creams, and a range other sporting goods have also been enhanced by nanotechnology. As well as developing textiles to withstand extreme environments, scientists have looked to naturally existing viral nano particles that live in some of the harshest environments on earth, for new building blocks for nanotechnology. A garment that senses their surroundings and interacts with the wearer is an area of considerable interest. Such textile-based nano sensors could provide a personalized healthcare system, monitoring your vital signs as you run up a hill or responding to changes in the weather.

Flexible Electronic Circuits:

Nano ribbons form the basis for the chips which are so flexible they can wrap around the edge of a microscope cover slip and so stretchable they can be twisted into a corkscrew. The researchers are focusing applications development in the healthcare industry and believe these tiny, flexible electronic sheets could one day be used to line the brain to monitor activity in patients at risk of epilepsy or be integrated into surgical gloves to monitor a patients vital signs during surgery.

Lifestyle Applications:

Perhaps surprisingly the earliest commercialized applications of nanotechnology are seen in lifestyle applications. Textile and cosmetics are among the first products to use nano materials. The examples of nanotechnology materials and technologies in lifestyle application are bullet proof vests. Nanotube fibers are used to make a material seventeen times tougher than the Kevlar. Future developments are to use nanotechnology to create Smart and Interactive Textiles (SMIT) that can sense electrical, thermal, chemical, magnetic, or other stimuli.

Application in properties of textile material:

The properties imparted to textiles using nanotechnology include water repellence, soil resistance, wrinkle resistance, anti-bacteria, anti-static and UV-protection, flame retardation, improvement of dye ability, Self-cleaning fabrics and so on. Among them important applications are described shortly.

Water Repellence:

Nano-Tex improves the water-repellent property of fabric by creating nano-whiskers, which are hydrocarbons and 1/1000 of the size of a typical cotton fiber, that are added to the fabric to create a peach fuzz effect without lowering the strength of cotton. The spaces between the whiskers on the fabric are smaller than the typical drop of water, but still larger than water molecules; water thus remains on the top of the whiskers and above the surface of the fabric. However, liquid can still pass through the fabric, if pressure is applied. The performance is permanent while maintaining breath ability.

UV Protective Finish:

The most important functions performed by the garment are to protect the wearer from the weather. However it is also to protect the wearer from harmful rays of the sun. The rays in the wavelength region of 150 to 400 nm are known as ultraviolet radiations. The UV-blocking property of a fabric is enhanced when a dye, pigment, delustrant, or ultraviolet absorber finish is present that absorbs ultraviolet radiation and blocks its transmission through a fabric to the skin.

Metal oxides like ZnO as UV-blocker are more stable when compared to organic UV-blocking agents. Hence, nano ZnO will really enhance the UV-blocking property due to their increase surface area and intense absorption in the UV region. For antibacterial finishing, ZnO nano particles scores over nano-silver in cost-effectiveness, whiteness, and UV-blocking property.

Fabric treated with UV absorbers ensures that the clothes deflect the Harmful ultraviolet rays of the sun, reducing a persons UVR exposure and protecting the skin from potential damage. The extent of skin protection required by different types of human skin depends on UV radiation intensity & distribution in reference to geographical location, time of day, and season. This protection is expressed as SPF (Sun Protection Factor), higher the SPF Value better is the protection against UV radiation.

Self-cleaning Fabrics:

A self-cleaning cotton fabric known as nano-care was developed and is marketed by an American Company, Nanotex and stain-resistant jeans and khakis are available since 1990. Nanocare fabrics are created by modifying the cylindrical structure of the cotton fibres making up the fabric. At the nano scale, cotton fibres look like tree trunks. Using nano techniques, these tree trunks are covered in a fuzz of minute whiskers which creates a cushion of air around the fiber. When water hits the fabric, it beads on the points of the whiskers, the beads compress the air in the cavities between the whiskers creating extra buoyancy. In technical terms, the fabric has been rendered super-non wett able or super-hydrophobic. The whiskers also create fewer points of contact for dirt. When water is applied to soiled fabric, the dirt adheres to the water far better than it adheres to the textile surface and is carried off with the water as it beads up and rolls off the surface of the fabric. Thus the concept of Soil-cleaning is based on the leaves of the lotus plant.

Anti-static Finishes:

Static charge usually builds up in synthetic fibers such as nylon and polyester because they absorb little water. Cellulosic fibers have higher moisture content to carry away static charges, so that no static charge will accumulate. As synthetic fibers provide poor anti-static properties, research work concerning the improvement of the anti-static properties of textiles by using nanotechnology were conducted. It was determined that nano-sized titanium dioxide, zinc oxide whiskers, nano antimony-doped tin oxide (ATO) and silane nano sol could impart anti-static properties to synthetic fibers. TiO2, ZnO and ATO provide anti-static effects because they are electrically conductive materials. Such material helps to effectively dissipate the static charge which is accumulated on the fabric. On the other hand, silane nano sol improves anti-static properties, as the silane gel particles on fiber absorb water and moisture in the air by amino and hydroxyl groups and bound water.

Nano Technology for Wrinkle Free Treatment:

Nano-Tex has launched a new nanotechnology-based wrinkle-free treatment that is said to offer an improved performance while preserving fabric strength and integrity providing an alternative to harsh traditional processes. Chemicals and processing methods reduce a fabrics tear and tensile strength. This means there are certain fabrics and garments that are Wrinkle-free textiles are popular and convenient for time-pressed consumers, but traditional not candidates for wrinkle-free technology, such as lightweight fabrics or slim fitting garments. Sometimes fabrics also need to be over-engineered or beefed up in order to withstand the fiber degradation caused by traditional wrinkle-free solutions. Either way, current technologies either do not work on all fabrics or the brand/retailer has to incur additional expense just to accommodate the destructive properties of wrinkle-free chemistry.

The nano-scale molecular structure in Nano-Texs new Fortify DP technology penetrates more deeply in the fiber to improve wrinkle-free performance. Additionally, it uses a longer and more flexible cross-linking chain which reduces fiber stress under tension, thus reducing the significant strength loss associated with traditional wrinkle-free chemistry.

Anti-bacterial Finishes:

For imparting anti-bacterial properties, nano-sized silver, titanium dioxide and zinc oxide are used. Metallic ions and metallic compounds display a certain degree of sterilizing effect. It is considered that part of the oxygen in the air or water is turned into active oxygen by means of catalysis with the metallic ion, thereby dissolving the organic substance to create a sterilizing effect. With the use of nano-sized particles, the number of particles per unit area is increased, and thus anti-bacterial effects can be maximised.

Economical and Environmental Aspects:

The unique properties of nonmaterials have attracted not only scientists and research workers but also businesses, because of their huge economic potential. The national science foundation reports that nano-related goods and services will increase to a US$ 1 trillion market by 2015. This amount is larger than the combined businesses of the telecommunications and information technology industries. Several hundred billion Euros are forecast to be created by nanotechnology in the next decade (24). The nano materials markets could expand to US$ 4 billion by 2007. It was believed that 2 million new employment opportunities would be created in order to meet the worldwide annual production demand of US$ 1 trillion in 10-15 years. Nanotechnology may impart favorably on the environment as well. By using less resource without sacrificing performance, nanotechnology may save raw materials and also upgrade quality of life.

This article was originally published in Textile learner blog run by Mazharul Islam Kiron.

Comments