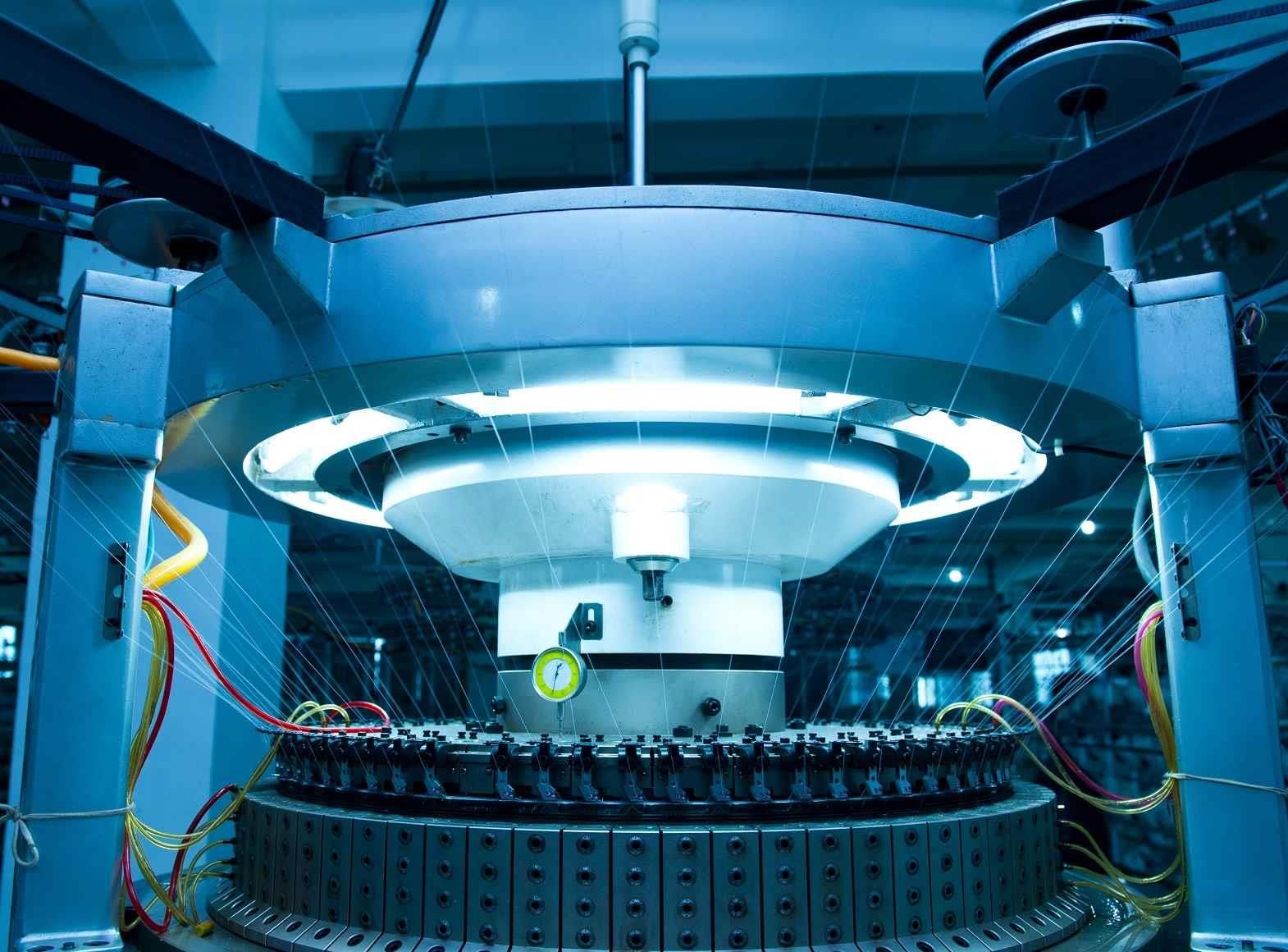

What it is: Technology for automated handling of cut fabric parts in the garment industry where parts are singularly collected from flat and delivered to a transport system. The devices consist of:

A reconfigurable passive hanger with 3 degrees of freedom (dof) and 3 clamps that can be turned on/off.

A reconfigurable modular robotic gripper with an articulated redundant architecture featuring 3 fingers and 9 dof.

Three picking modules pneumatically actuated and embedded into the gripper fingertips.

Picking Technique: Each fabric part is picked at exact locations determined part by part to avoid folding and minimize wrinkling in the hung configuration. High flow-rate vacuum is applied at each picking location to generate holding forces, making it safe and robust for use with porous materials like fabric, with adaptation to curved contact regions.

Hanger

- Hanger architecture and geometry are defined through extensive analysis of cut part shapes to provide support.

- It satisfies minimum lateral space requirements.

- The overall cost is very low, involving a few plastics and aluminum components.

- It is suitable for both automatic and manual operation.

- Consists of 3 actuated arms, each with one picking/loading unit at the tip.

- The central arm has 1 degree of freedom, while the lateral arms have 2 dof to correspond to hanger motions.

- It features distributed onboard generation of vacuum by new micro turbine modules.

- Interfaces with a robotic arm and distributed control unit.

- Has an interface and docking system to the hanger, facilitating full hanger management, including reset and configuration, part loading, and management of hanger graspers.

- Utilizes 4-bar linkages in lateral arms to drive picking modules.

- Employs design solutions to minimize mass.

What is the innovation/special feature

The robotic hand embeds high-flow vacuum picking modules with micro-compressors onboard. Fabric parts are grasped and handled by multi-functional fingers. Fabric porosity is not a problem as for other vacuum systems. Clamps are actuated using SMA.

The grasping solution proposed is a system including a reconfigurable gripper and a hanger. This allows concentrating movement dexterity and intelligence in the gripper while the hangers are passive and cheap. So the system cost is kept low because only one gripper serves a cutting table unloading cell but many hangers are used to run the cut parts to the sewing sections.

The metamorphic reconfigurable grasping device is able to handle cut parts of different sizes and shapes, made of different kind of fabric without damages.

The innovative architecture of the gripper offers a great dexterity in a working space suitable for a great variety of man and woman clothes; its modularity is very useful for quick maintenance, fast substitution of the picking modules on the fingertips (maybe adopting different picking technologies) and relative set-ups.

A further innovation is the gripper control that is integrated with the robot control so the information about the poses of the picking points on the cut parts are shared and the positioning can be achieved with the due accuracy on the basis of all the motilities of the robot and gripper. Many tricks have been adopted in order to make hangers simple, lightweight and cheap. With this purpose the clamps are actuated by SMA springs purposely designed and the electric circuitry used for SMA heating is embedded into the hanger structure.

Cutting table with automatic unloading

A robot equipped with robotized gripper grasps the cut parts and dispatches them in the plant. This system will satisfy the need of automation of the unloading operations of parts after cut. The robot can be a standard industrial arm or a special manipulator depending on specific requirements. The gripper can comprise fingers and different grasping units. A RFID-ZigBee labeler can be embedded as well.

The robot dialogs with the cutting table, learns the positions of the cut parts, knows the needs of manufacturing, decides which parts to grasp, grasps, unloads, realizes these parts to the transport.

The cutting table shares with the unloading system all information regarding part geometries and their nesting on the table, the material, the presence of plastics and paper, the number of plies, specific requirements regarding the fabric and its unloading. This information is used by the unloading system to plan the grasping and lift conditions.

Information about the unloading sequence is received from the cell or line control system. The unloading system dialogs also with the logistics of the plant either directly or through the cell/line controller.

The unloading sequence is carried out picking one or more parts at a time depending on dispatching requirements, size of the parts, specific architecture of the gripper.

The gripper is reconfigurable and can adapt to each part geometry. High-flow vacuum is used to generate the adhesion force. The working conditions can be modified to adapt to specific material requirements.

The gripper can embed equipment to transfer information in RFID-ZigBee markers onto the parts if required. The integration to the cell/line is complete.

The system realizes the automatic unloading of the fabric parts from the cutting table, operation done manually today. Accurate handling of fabric is difficult. The system allows extending automation to the following garment manufacturing sections.

The innovations in the system are in the adhesion technology adopted and in the level of flexibility which is higher than in any other previous technical experience.

The adhesion to fabric is obtained using a high-flow vacuum generator with depressor, control and every other functional component onboard to realize an independent module. Fabric is porous to air and delicate, especially garment types. The appearance of the surface is modified by any mechanical interaction comprising relative contact movements. Traditional vacuum solutions do not process an amount of air sufficient to obtain reasonable grasping force on fabric. Dynamic depressors are used to hold and grasp porous material but the architectures are generally centralized with one main generator and distribution channels. This limits the achievable flexibility. The innovation in the adhesion technology consists in the development of distributed dynamic depressors with low-cost that can be treated almost as Venturi-depressors in terms of complexity, size, mass, cost. These dynamic depressors can be distributed on any equipment with multiple picking points. The reliability of the overall system results improved because fail of one picking point does not compromise the overall functioning of the system as with centralized generators. A special features of the picking module developed is the adaptability to different materials with porosity to air in a large range without structural modifications to the module.

This article was originally published in the November issue of the New Cloth Market: the Complete Textile Magazine from Textile Technologists

Comments