Carbon fibre reinforced plastic (CFRP) is the advanced innovation of the20th century, says PradeepKulshrestha.

The end of the Metal Age is here.The age of carbon fibre reinforced composites has just begun. Wherever a massneeds to be accelerated or slowed down, lightweight design is urgently neededto achieve high energy efficiency. In case of an accident, CFRP absorbs abouteight times more energy than steel or aluminum do. This becomes especiallyobvious in the aviation industry. If an airplane is lightened by a kilogram,its fuel consumption is reduced by approximately 3,000 kg over its lifetime.

Carbon Fibre Specifications

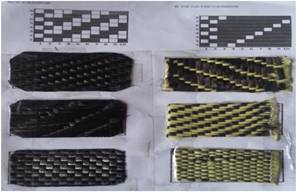

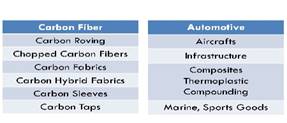

Carbon fibre reinforced plastic isa material that will create demand in future for aviation Industry, theautomobile industry, the wind energy sector as well as the shipbuildingindustry. Carbon weaving produces the fabric in Uni Directional Carbon fabric(UD) or Bi Directional Carbon Fabric (BD), according to end use. Fabric can bewoven in different weaves like plain, twill or satin.

Carbon fibre reinforced plastic isextremely light weight, stable and immune to wear and tear.

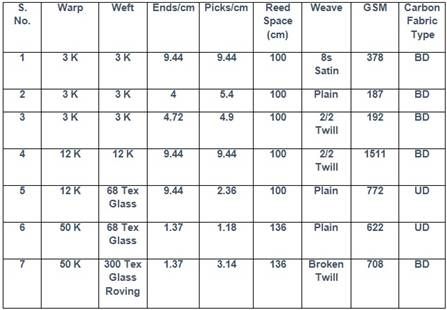

Carbon fibre fabric construction particulars:

Pic 01: Spools of Carbon Fibre

A standard amount of carbon fibre

in thousands bundled in roving form is wound on spools.

1 K Carbon Fibre - 1000 filaments

3 K Carbon Fibre - 3000 filaments

6 K Carbon Fibre - 6000 filaments

12 K Carbon Fibre - 12000

filaments

24 K Carbon Fibre - 24000

filaments

50 K Carbon Fibre - 50000

filaments

We conducted research in Nirma

University, Ahmedabad in the Civil Department to repair damages on extremities

of beams.

Carbonfabric (24 K UD Carbon) for repairing building beams:

Cutting carbon fabric (CF) for

axial beams in construction

Application on final layer applying

resin

Layering of carbon fibre for

flexural beams

In this way for multi-storied old

buildings, the damaged beams can be repaired without removing basic

infrastructure.

Carbon Hybrid Fabrics

Cost effective and composite

applications

Carbon fibre fabric can be woven

with aramid glass for composite application, for aerospace fabric and carbon

rings, carbon rods for artificial limbs, wind energy, sports goods, marine,

automotive and infrastructures.

Carbon product variants and applications:

Conclusion:

Properties of CFRP have brought

high safety to motorsports and have also made vehicles more powerful. Moreover,

vehicles with less weight consume less fuel, which is a benefit for everyone's

budget as well as for the environment.

The lightweight potential of CFRP

can be used for many apllications. CFRP leads to making very light and

therefore energy-efficient aircrafts, vehicles and ships as well as larger

rotor blades for more powerful wind turbines. CFRP can lead to the making of

longer bridges, higher buildings or sel-supporting roofs with wider spans.

Although these are some of the

common uses of carbon fibre, many new applications are seen almost daily. The

growth of carbon fibre is fast, and in just five years, this list will be much

longer.

Reference:

1. Fibre2fashion.com

2. Iimts.edu.in

3. Mueller-frick.com

4. Itmaasia.com

5. Teijin.com

6. Research Work at Nirma

University, Ahmedabad

About the author:

Pradeep Kulshrestha is DGM - weaving, Chiripal Group. He has three decades of experience in textiles and research projects in technical textiles and composite applications.

Comments