It is time to reduce motor running loss to optimise textile parameters, says Ashok S.

Industry managers often presume that they have reduced motor running losses through preventive time-based maintenance schedules. Condition-monitoring the motor has shown us daily that we lose energy through trivial aspects in motors and loads.

The input-output ratio i.e. efficiency of each sub-system in the motor multiplies for overall efficiency to drop appreciably. Compared to drop in efficiency in the load over years, the drop in efficiency in motor is less, but the same can be focused now to reduce the cup-to-lip losses from the motor input to the output load.

Existing textile spinning mill ring frame motor working

Motors running with the following parameters face reduced efficiency. They are:-

1. Motor loading is at the inefficient 50 per cent loading. The same can be revisited to change loading pattern.

2. Motor is now retrofitted with VFD and the new motor can be sized less to avoid under-loading.

3. Motor is not able to ventilate as it is totally enclosed and gets heated up by surrounding pneumafill air.

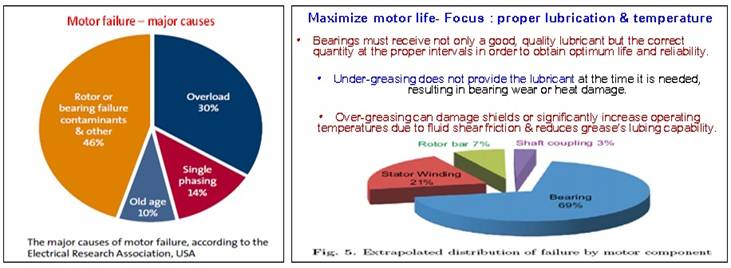

4. Motor needs periodic lubrication with poly urea thickened specialty grease and needs extended re-greasing interval.

5. Losses in power transmission are more now from motor through belts, pulleys, tin roller bearings, tapes upto the spindles.

Is motor loading band efficient?

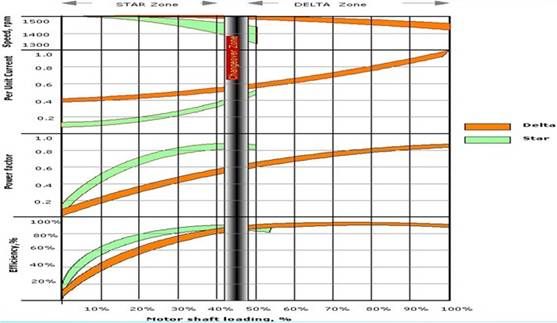

Take the case of 1200 spindle long frame, the existing motor is 55 KW rated and the loading is around 40 to 50 per cent inefficient average loading only. We presume that the motor is now in the threshold start of efficient loading zone, but it is not so. The motor loading is the first and foremost factor to improve its running efficiency.

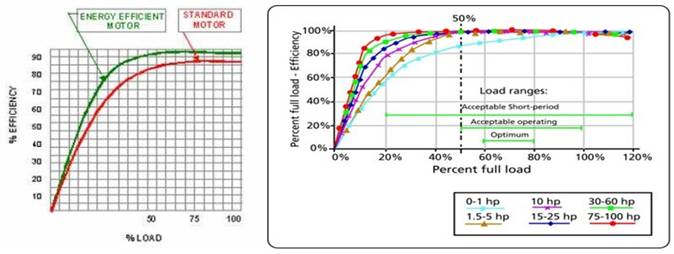

Any motor run at slightly less than half loading capacity is losing efficiency due to the droop characteristic in the inverted flat bell shape in the Loading Vs Efficiency curve for the old IE 1, IE 2 motors. The universal rule is, when the motor uses less than half the loading capacity, it is prone to efficiency drop. The flat efficiency band is broader in IE 3 and IE 4 motors and slope is elongated, gradual and not steep, compared to the decade-old IE 1 rated motors. But as a motor user, we must first monitor the motor so that the same motor is always loaded above 60 per cent to obtain optimum efficiency.

The above shown in the previous page expresses that standard motor versus energy efficient motor versions; the loading versus efficiency in mid region; and the efficiency varying with respect to motor loading per cent. Again, this starts from 40 per cent threshold values for flat efficiency.

A motor's rated efficiency as per name plate is important to the user, whereas the motor efficiency at the operated loading range is more critical to the user now. If efficiency drops drastically below 50 per cent and the mill is operating the motor at 50 per cent threshold, then its efficiency is likely to fall steeply in that region. It is like running a car in third gear on a clear road when the fourth gear should be used.

This efficiency drop is abnormal in some brands and in the old IE 1 and IE 2 motors, but in latest IE 3 version motors and above, efficiency drop is less, and smoothly broadened to take the motor to efficient operating zone as well.

Mill should monitor its motor average Kilo Watt Hour (KWH) consumption

The industry needs to fix KWH meter to the motor for any motor above 5 HP, running for two shifts a day. The cumulative daily KWH value along with the run hour meter will indicate that motor's daily, weekly and monthly cumulative KWH to study the relative efficiency workings for the given machines.

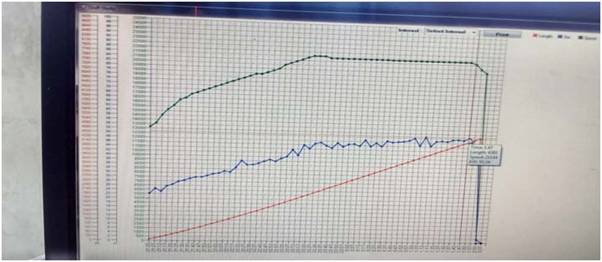

Green line: Speed.Blue line: KW. Red line: Hank length

The power and production monitoring of ring frame in the graph can give inputs to the mill about the input KW variation versus the output in spindle speed and yarn length in meters. The above chart's figures must give priority to productivity/frame, but the graph has to give inputs to the maintenance dept to optimize speed setting steps to achieve power saving.

The graph clearly shows speed setting pattern is not optimised and hence resulted in slow KW ramp in the inefficient region up to the 50 per cent for quarter Doff cycle. This can be fine-tuned by immediately ramping to higher speed setting from 10 per cent of hank length and this is subject to good raw material and machine smooth running conditions. This graph also shows KW jerking in each speed setting and this is abnormal. It shows friction in bearing, belts, tapes/tin roller bearing greasing load etc. This jerk must not happen in every speed step increment input, if the machine is maintained well, mechanically.

What steps should be taken when replacing the motor to ensure enhanced efficiency?

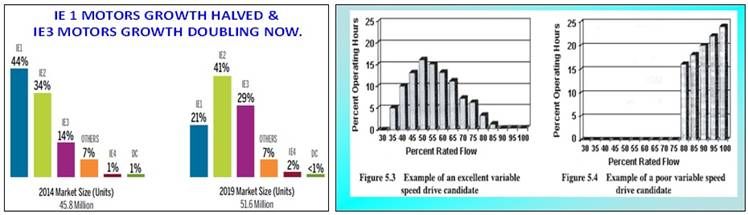

It is time that the textile mill has to replace their motor with the IE 3 version, to achieve higher part load efficiency and now being used for inverter duty, this motor comfortably achieves higher efficiency and sustains the same efficiency in the longer run.

1. This will make this new Totally Enclosed, Fan-Cooled (TEFC) inverter duty motor to sustain its efficiency in the long run when retrofitted with the Variable Frequency Drive (VFD) now.

2. The motor is soft starting by the VFD, and the previous motor's running averaged KWH per hour is around 50 per cent of motor rating only for the yearly/monthly average count on the ring frame, so the mill can go for 45 KW rated IE 3 version motor instead of 55 KW for 1200 spindles. In fact, now the trend is that the ring frame OEM gives only the machine and asks the mill user to choose themotor KW size, to suit to their spindle speed, maximum and average KW requirements, and other textile parameters.

3. The above alternative is suggested for 50 per cent loaded replacement of motors. If the motor average KWH is already loaded around 60 to 80 per cent band, then we must replace with the same size of motor rating only. So the mill has to replace with new motor KW rating, suiting to frame conditions, and the mill's production requirement of spindle speeds, as per spin plan.

4. To reduce the grease-load imposed by the old worn-out grease in motor, tin roller's multiple-time re-greased bearings by replacing the existing grease with Polyurea thickened special grease or replace worn-out tin roller bearings, if required.

5. This exercise costing rupees three thousand only per frame can be executed in two shift working hours by the maintenance team. Savings can be recorded.

6. The mill can practically think and discuss with the OEM to provide better cross ventilation inside the hood, where the motor is housed, and duct out the pneumafill air to trench, separately.

7. Provide a meshed hole (bigger than the motor fan cowl size) in the hood wall facing motor Non-drive side. And provide a loosely fitted duct from the motor fan to the meshed holes area in the side wall of hood. This will facilitate the motor fan to suck fresh outside-air through the side wall of hood. As this modification had been already implemented in the Autoconer machine suction motors, the same mesh provision can be given on the hood wall.

8. Alter the grill mesh pattern of motor fan cowl grill on NDE back side. This will facilitate free fresh air flow to the fan cowl grill externally and allowcooler air to pass through the motor fins, thus cooling the motor skin faster than before.

9. Think globally and Act locally: - IE 3 motors' global growth is doubling now, because the user can have both the benefits of better motor efficiency and inverter compatibility. Also sales of IE 1 motor will be half only from now on. So plan to rate your existing motors now. Motor with more running losses per day, must be out of the mill immediately.

10. When using the inverter, the optimum range is to keep below 50 Hz. Above 50 Hz, the friction and windage losses increase in motor, so it is better to resize the pulley of motor and tin roller shaft, and optimise the motor frequency (for less power consumption) to suit the required spindle speeds, after pulley re-sizing.

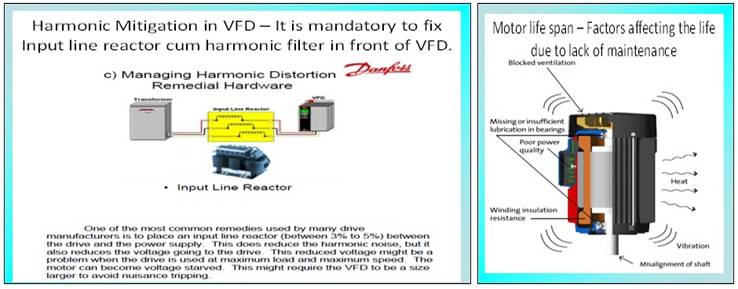

11. Now the VFD must be fitted with line reactance choke of 3 to 5 per cent ratings (to ensure around one third of harmonic reduction at source), for house arresting harmonics at VFDsource end, and for the sake of VFD protection against incoming power surges.

12. For the ring frame motor application, since the motor is always loaded less than 70 per cent average, even the voltage reduction at motor terminals, happening due to input line reactance. Choke is good and this improvesthe motor operating efficiency range.

Motor lubrication and ventilation to improve now

Added to that, the motor is not effectively cooled by the hot harsh fluffy pneumafill air from the pneumafill fan, compared to the ambient surrounding conditions. Now many of the mills are using thermal imager to find the temperature near to the motor surrounding areas inside the hood. This is always 5 to 7 Degrees C hotter than the ambient mill condition around the frame. So it is better to divert the air down by isolating through an expanded duct directly to the exhaust trench without touching the motor. Allow the TEFC motor to suck cooler ambient external air from non-drive end to blow to the motor skin.

When the motor is operated in a poorly ventilated area where heat transfer from motor skin to surroundings is poor, the enlisted major causes of failures of motors act fast to reduce the life of the motor. The motor's thermal characteristics deteriorate faster due to surrounding harsh hot air flow leading to fall in efficiency. Do not over-grease the bearings, as the same will act as extra load. Under-greasing leads to hot spots and this will lead to mechanical breakdowns.

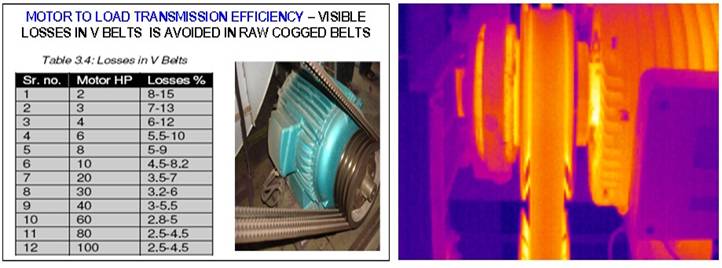

Motor belt transmission losses

The motor to tin roller shaft is linked by flat belt or by raw cogged belt. Earlier, the machine OEM gave this belt specs during installation. The belt is rated for 55 KW, harsh starting by Star Delta starter type before. Now the user has retrofitted VFD to the same motor and is running the motor at max 75 per cent KW of the rated motor power. So the factor of safety could have been designed more, on the belt and pulley design by extra per cent points, on the belt and power carrying capacity. The same can be discussed with machine Original Equipment Manufacturer (OEM) and downsized immediately.

Based on the VFD smooth and soft starting pattern and considering the two third loading as maximum average, the flat/raw cogged both the belt and pulley specifications can be sized to match the actual optimum power requirements. This trivial belt and pulley sizing also can yield KW reduction in between and will reducethe overall ring frame motor KW to spindles.

Low cost power saving solution for the same Non-VFD motor

The above procedure calls for replacement ofthe motor. If the mill wants energy savings by retaining its decade-old motor in the inefficient loading mode, then the mill can try this damage control exercise by retrofitting the gadget automatic Delta to Star convertor gadget in their machine panel. After the motor is started by the Star to Delta mode, this gadget monitors the motor running current and converts themotor mode from Deltato Star, if running load current is less than 40 per cent of the full load ratings. The simple payback period for this retrofitting measure is only a few months.

This will give savings of around 3 per cent in KW consumption when running on star mode and the savings can be seen each day if the star mode is running for atleast one-third of a day during the repeat Doff cycles. So this retrofit is applicable to oversized ring frame motorand its loading average KW isless than 40 per cent of the rated motor KW for minimum run of one-third time of theDoff cycle. This saving is more appreciable in fine count yarns, where the Doff cycle runs for more hours and during that time,motor load variation is from 20 per cent to say 70 per cent.

Many old textile mills have tried this low costroute to achieve savings in KW and more in KVA (Kilo Volt Ampere) now. But this is only a damage control exercise for this lightly loaded motor.The case study shows, 55 KW rated ring frame motor was consuming running at 20units per hour average in Delta mode,over its DOFF cycle. After retrofitting this Delstar converter, the same motor consumed only 19.4units per hour average over its Doff cycle, due to power saving in Star Mode, 0.60 unit per hour and say 3 per cent power saving.

Many mills have been losing around three per cent power all these years, due to the Inefficient loading pattern and the same loading inefficiency can be corrected by this retrofit. Now the mill is planning to buy the latest IE 3 version motor to realise the above savings by replacing their old motor. So first, to confirm the loading of motor is in its efficient zone. Then plan for latest IE 3version motor, sized to the machine condition and optimum spindle speeds, TPI and TM and the Spin Plan.

BEE guidelines on energy saving in underloaded motors: Motor shaft loading versus efficiency chart

Conclusion

Over a few years, many mills changed to VFD motor control to achieve the day-to-day flexibility of operations, to suit to daily mill spin plan, for energy savings and for increase in productivity. But it is time the mill ensures their VFD is compatible with the present IE 3 version motor meant for inverter duty. The mill's job is incomplete if the matching motor is only the same Standard IE1 motor, and not upgraded to IE 3 version motor.

The objective of providing VFD and inverter duty motors is to achieve energy savings and improving Operating Profit Margins (OPM). So, mills need to make use of the VFD potential for improved motor safety and energy savings, and overall productivity improvements at the touch of a button.

Please look for savings in UPH and UKG for healthy running of ring frames by VFD IE3 version motors and relative condition monitoring to target energy reduction. Please make your ring frame electrically and mechanically healthy by fine tuning and optimising the textile parameters to achieve energy savings and monitor the same daily.

About the author:

Ashok. S is a BEE Empanelled & Accredited Energy Auditor from Coimbatore and the Chairman of IAEMP Coimbatore chapter, India.

Images courtesy:

1. Honeybee Automation, Cbe

2. DANFOSS Knowledge sharing VFD lessions

3. GRUNDFOSS motor guide

4. Motor Efficiency Guide

5. BEE Bureau of Energy Efficiency guide books

6. Electrical Research Association USA.

Comments