Nanofibreshave a variety of applications in face masks, water filtration and cigarettefilters, says

Nanotechnology was conceived inSouthern California in 1959, when Nobel laureate physicist Richard Feynman gavehis now-famous lecture at California Institute of Technology, Pasadena. It wasput forward in 1974 by Japanese Scientist Norio Taniguchi, who describedmachining in the range of 0.1 to 100 nanometers (nm).

Use of nanotechnology-basedultra-fine fibres and functional finishes in enhancing performance in textilesis growing fast. These are aimed at imparting antibacterial, moisture control,UV-resistant, water-repelling and wrinkle-resistant properties. Research isalso under way to use nanotechnology for protection, hygiene and health.

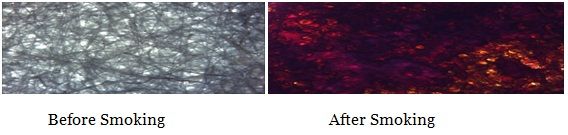

Nanofibres are fibres withdiameters in the 50-100 nm range with large specific surface area, highporosity and small pore size. These can be used to prepare filters for virusesand bacteria in face masks, tar and nicotine filters in cigarettes, to reducerelease of solid particulate matter (SPM) into the environment and to produceenergy-efficient water purifiers.

Ahmedabad Textile Industry'sResearch Association (ATIRA) has developed a nanofibre-based mask, which itclaims, filters 99.9 per cent of H1N1 virus. The nanofibre has amicrometre-thick coating of nonwoven material that does not affect air flow orincrease the weight of the mask. Rather, it significantly improves the mask'sprotective properties. A network of fibres of about 100 nanometres in diameterand about 1000 times thinner than a human hair offered a larger surface area ofthe face mask. The nanofibres contain silver nano particles about 50 nanometresin diameter that are capable of even killing viruses. For face masks, either singleor a combination of nanofibre layers on a substrate is used as the middle layerbetween the spun-bonded nonwoven layers.

Nanofibres are also usedto prepare filters for cigarette smoke without affecting the pleasure ofsmoking. Additional filter discs made of nanoweb to filter harmful contaminantsare attached externally to the cigarette filter.

Nanofibre-based energy efficient membranes are a new breed of membranes with advantages like better energy efficiency and higher throughput. A nanofiltration (NF) membrane can be placed between the steps of ultrafiltration and reverse osmosis. Nano silver particles are added to impart anti-microbial properties to nanofibre layers. Nano silver particles in fibres help inhibit growth of odour-causing bacteria and fungus and are increasingly finding application in the personal and home hygiene sector.

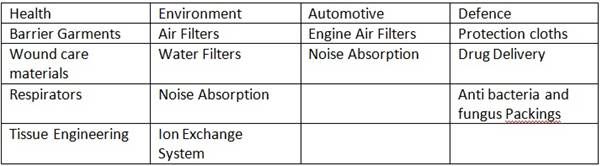

Applications of nano technology

About the author

Pradeep Kulshrestha is a textiles operations management expert. He is currently with Nandan Denim Limited (Chiripal Group), Ahmedabad as DGM, denim & shirting.

Comments