The single-head draw frame generation from Rieter offers an unprecedented level of productivity with the highest quality standards. The SB-D 50 draw frame without leveling is flexible in application and has numerous interesting features, including a patented sliver guide, unique sliver coiling and an efficient suction.

The demand for single-head draw frames is increasing as it is not always the high volumes that are needed. Many spinning mills offer special yarns or blends in small ranges for which the SB-D 50 draw frame without leveling and the RSB-D 50 autoleveller draw frame are the perfect solutions. They distinguish themselves from the competitors by high delivery speed at consistent quality. They produce at a delivery speed of up to 1 200 m/min whereby the speed could be increased by up to 33 per cent compared to the previous model depending on the fiber material.

Newly, the SB-D 50 is also available in Indian rupees and, thus, is an attractive package together with the RSB-D 50 autoleveller draw frame in terms of economy and easy operation. They both distinguish themselves by their high level of productivity and share the same spare parts as well as the same operating concept. For customers who need an uneven number of draw frame heads, the SB-D 50 can also be combined with the Rieter double-head draw frame SB-D 26. In addition to its flexible application possibilities, the SB-D 50 is characterised by several interesting features (Fig. 1).

Fig. 1: The draw frame SB-D 50 delivers great results regarding productivity as well as quality and is easy to operate.

Consistent sliver quality at all times

The patented sliver guide from Rieter which also comes with the SB-D 50 guarantees centric sliver guidance and consistent sliver quality at all times. The most common error that occurs with conventional sliver guides is a non-centric guidance of the sliver. The reason for this is that the sliver guides in front of the drafting unit are often wrongly adjusted leading to uneven drafting and creating also thick places. This is avoided with the patented sliver guide from Rieter. It ensures that the web width is reproducibly set by simple turning of the guide elements (Fig. 2). The geometry of the 4-over-3 drafting system allows close cylinder spacing and therefore also good processing of short fibre lengths. Additional fibre guides in the main drafting field prevent lateral slipping of the edge fibres. Fewer disturbing faults in the yarn are the result.

Fig. 2: Centric sliver guidance and consistent sliver quality at all times

Perfect in coiling

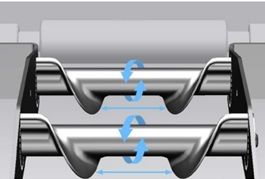

The SB-D 50 has the right coiler for different needs. CLEANcoil is the standard coiler for all fibre materials and therefore offers maximal flexibility. The spiral coiling tube ensures coiling which is free of drafting faults, even at high delivery speeds. A honeycomb structure on the coiler underside reliably prevents deposits.

For the processing of 100% polyester, the latest development CLEANcoil-PES with a new type of coating offers unique advantages in coiling. Even with critical polyester fibres, the cleaning cycle can be extended by at least 100 per cent compared to the standard coiler. This also leads to more consistent sliver and yarn quality.

Unique sensor for exact first sliver coils

Cans with plates that are too low are annoying in most spinning mills. They lead to tangles and also to breaks when drawing the sliver out of the can in the subsequent process. The SB-D 50 solves this problem with a contact-free precision light barrier (patent pending). It detects when the first sliver coils make consistent contact with the coiler and only then switches the machine from the slow mode to full production speed (Fig. 3). This guarantees controlled sliver coiling also in cans where the plates are too low, and ensures consistent sliver and yarn quality. At the next process stage the cans therefore run without interruption until they are completely empty. This maintains machine efficiency at a high level, reduces operator intervention, eliminates sliver waste and keeps quality on a consistent level.

Fig. 3: Unique sliver sensor ensures controlled sliver coiling also in cans where the plates are too low.

Even when only a small number of can plates are too low in a spinning mill, the new sliver sensor brings considerable advantages. Assuming 5 per cent of the annual filled cans are affected, it sums up to more than 3,600 cans for each draw frame. This leads to about 2,300 kg of waste which can be avoided by the sliver sensor.

Reliable sliver separation without additional mechanics

Materials with a high fibre-to-fibre cohesion, like for example 100% polyester, need a sliver separation between filled and empty can for a trouble-free can change. Other products require a rather complex mechanical device here which causes wearing costs and comparably difficult settings. The SB-D 50 has a more elegant solution for this: Between the drafting system and the draw-off calendar a thin place is generated which is transported below the coiler and deliberately breaks at can change – without the need for additional parts.

Simple setting of suction intensity is a standard

Trash and dust on the pressure bar lead to sliver funnel blockages and impair the quality of the yarn. The efficient suction concept from Rieter ensures that – through the lifting of the cleaning lips − trash accumulations are removed directly via the suction. Practical tests confirm fewer sliver funnel blockages. The increased yarn cleanliness is shown in reduced imperfections and Classimat faults as well as in lower number of yarn clearer cuts.

Only on the Rieter draw frame, the operator can set the suction intensity easily and rapidly on the machine display as a standard. The setting is easy to reproduce. This simplifies not only material change but also eliminates quality deviations when, for instance, several draw frames are feeding sliver to one assortment.

Easy operation and rapid assortment changeover

The SLIVER professional expert system is integrated in the machine. The direct adoption of setting recommendations allows a rapid assortment changeover with best sliver quality which can easily be done even by less trained operators. It comprises a convenient setting of the delivery speed, coiler speed and suction intensity on the touchscreen via frequency-controlled drives (Fig. 4). High visibility LEDs indicate the condition of the draw frame and further simplify the work for the operator. A colored touchscreen facilitates intuitive operation.

Fig. 4: Rapid assortment changeover with SLIVERprofessional expert system on the touchscreen

Comments