Oil spill is a global menace - its polluting effect on aquatic life and birds leads to cascading effect on the ecology. Though oil spill prevention is not within our control, avoiding its spread and removal from water bodies can be effectively managed. Textile fibres with adequate modification can be used as effective oil sorbents or moppers.

No matter where and how we live, aquatic life is directly or indirectly connected to us. Even if we don't eat seafood, fishmeal is used to feed poultry and organically fertilise crops. There are many things which damage not only the fish but also the corals and the hydrophytes of our oceans. One of the most common problems encountered is oil spill consisting of harmful chemicals which are very damaging to the aquatic life.

Oil spills can happen due to many reasons like natural disasters, accidents during oil drilling, equipments breaking down, and accidents during transportation of goods by ship, storage and use of oil. Such oil spills occur in seas, rivers, lakes and even on the land surface. They affect birds, as the oil coat on their feathers makes it difficult for them to fly. Oil spill itself is not the only thing that pollutes the environment but also the methods and measures used for mopping up the oil can be risky to the environment. The amount and toxicity of chemicals used to break or remove oil from water is scary.

Though oil spill prevention is not within our control, avoiding its spread and removal from water bodies can be effectively managed. The density of oil is less than water - it floats on the water surface when it leaks or spills. Thus, surface mopping is considered as the only means of oil recovery. For this various containment equipment are used.

Commonly used containment equipment are floating barriers called booms which are used to contain or prevent the spread of spilled oil. Then, the skimmers are there which work like vacuum cleaner - they suck up the oil from the water surface. In some cases manual labours with rakes and shovels remove the oil. Another method is in-situ incineration, where the oil floating on the surface of water is ignited and burned off. However, the disadvantage of this method is generation of toxic fumes released from the burnt oil.

Sometimes the clean-up operation is left to the quirks of nature, like the sun, wind, weather, tide or naturally occurring microbes. While the more sophisticated methods involve use of sorbents - materials that immerse liquids by pulling in through pores or forming a layer on the surface. The water contact angle is used to measure wettability of the surface, which closely relates to the sorption of oils. Sorbent for oil sorption is selected on the basis of its porosity, low density and high surface area. The other properties of the sorbent include mechanical and chemical stability, recyclability and good buoyancy.

The textile fibres which are ideally suitable as sorbents for oil spill mopping are natural products such as cotton and kapok. Economical and readily biodegradable plant biomasses such as wood chip, rice husk, coconut husk and bagasse are used as inserts to enhance the sorption property of the textile fibres. The silkworm cocoon waste is found to remove 30 per cent more motor oil and vegetable oil from marine water than other protein sorbents. The fruit peels of banana and orange which are rich in cellulosic content, is found to remove heavy oil more effectively than lighter oils. The cellulosic materials show higher uptake of marine fuel with less treatment as they are fluffy and possess low bulk density.

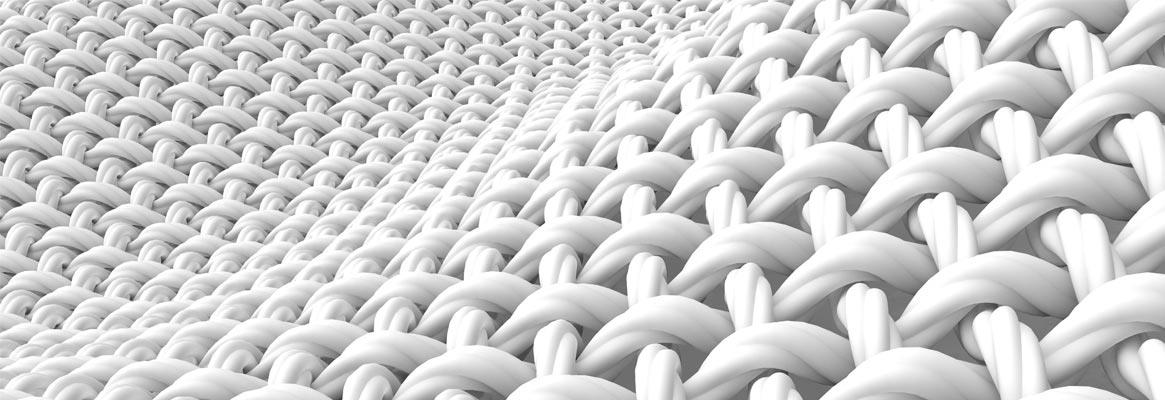

Nonwovens containing unbleached cotton are found to be more effective than synthetic sorbents while the aerogel microspheres obtained from polyvinyl alcohol (PVA) and cellulose nanofibril (CNF) are found to exhibit outstanding oil sorption capacities for floating oil mopping. Animal hair keratin is hydrophobic and bio-sorbent, which means it repels water and attracts oil. It is also an abundant, renewable resource. The fibrous tunicate cellulose nanocrystal (TCNC)-based super hydrophilic and underwater oleophilic membrane is found to be highly effective sorbent for oil mopping.

Bioremediation refers to the use of specific microorganisms to remove oil. Here, different classes of bacteria, fungi, algae etc are used to degrade petroleum products by metabolising and breaking them into simpler and non-toxic molecules. The efficiency can be increased by adding phosphorus and nitrogen-based fertilisers which provide adequate nutrients to the microbes so that they are able to grow and multiply quickly.

Thus, the use of appropriate sorbent makes the process of oil mopping much easier, effective and efficient. The sorbent allows the recovery of the oil and reuse of the sorbent material, which is considered environmentally-friendly and economical. The natural fibres having nano-porous voids are considered ideal because they are available in abundance and are non-toxic. Such sorbents are structured into sheets, booms, or pads, which are reusable and easier to control in both open and confined spaces.

The availability, steady supply, and price compatibility of raw cotton are some of the properties which promote the use of sheets or pads of cotton-containing nonwovens. Generally, the low grade cotton fibres are considered unsuitable for apparel wear, but now they can be effectively used for oil spill mopping. The current market share of cotton fibres is only 4 per cent in the nonwoven industry. Thus, using cotton as an oil-sorbent could lead to a major impact on the end-use of these fibres. Also, research findings indicate that natural fibres have three times greater oil sorption capability compared to synthetic ones.

Generally, oil spill takes a toll on fishes. So oil mopping is important for aquatic life protection. The natural fibre based sorbents are found to be highly effective in overcoming the menace of saving marine as well as human life.

Comments