Abstract: Antimicrobial and eco-friendly maternity apparel is becoming increasingly popular among modern consumers. Antimicrobial technology is used to establish a long-lasting defence barrier against odour-causing bacteria, mould, and fungus. This also helps to keep the product fresh for longer and boosts the wearer's confidence. To make pregnancy and post-maternity clothing eco-friendly and to preserve feeding hygiene, anti-microbial finishes are applied. The process of developing anti-bacterial maternity apparel is described in this paper. N9 pure silver was applied on the maternity wear fabric using exhaust technique and the efficacy of its anti-microbial property was tested with bacteria Staphylococcus aureus and Klebsiella pneumonia, before and after 20 washes and found to be effective.

I. Introduction

Antimicrobial characteristics are not inherent in textile materials. Sweat allows bacteria to flourish because of the intrinsic characteristics of textile fibres. Humidity and heat worsen the condition even more. Microbial attack causes staining and degrades the performance of textile substrates. Textiles are treated with an antibacterial finish to protect the wearer from scent and the textile substrate from degradation. Antimicrobials are used by several well-known textile companies and manufacturers to add value to their existing range of textiles or garments, which they can pass on to their end customers. Hygiene for textiles is becoming a top issue in terms of functioning, as clothing is the closest thing to human skin, touching it in some way every day. Humans are protected from the elements by their clothing, which acts as a second skin. [1]

In addition, the inherent characteristics of textile fibres allow space for microbes to flourish. The structure of the substrates and chemical processes may promote microbial development. The condition is exacerbated by a humid and warm climate. Microbe infestation causes pathogen cross infection and the development of odour where the fabric is worn near to the skin. Microbial assault is also responsible for staining and loss of performance qualities of textile substrates. Antimicrobial finishes are applied to textile materials in order to protect the wearer and the textile substrate itself.[2] As the need for fresh-smelling, skin-friendly, high-performance fabrics grow, antimicrobial textile products are becoming more popular. Many specialty applications, such as sports textile, demand modern performance materials. These must perform well in terms of endurance and durability, as well as by imparting antibacterial qualities to the fabric. These qualities, as well as the comfort and hygiene factor, can be increased, making them more enjoyable to wear. Odours can be neutralised, and skin problems caused by microbial growth can be decreased, emphasising the treated product's hygiene. [3]

Antimicrobial agents stop infectious bacteria from growing and kill them when they come into touch with them. These antimicrobial compounds are widely used in textile fabrics for hygienic purposes related to human health issues such as preventing bacteria from spreading, controlling infection, controlling odour, and healing wounds, among others. [4]

Antibacterial treatment of textile materials is required to achieve the following goals:

• To avoid cross infection by pathogenic microorganisms.

• To use microbes to control the infestation.

• To limit the creation of scent by stopping the metabolism of bacteria.

• To protect the textile items from stains, discolouration, and deterioration in quality.

The comfort function is the most significant feature of maternity clothes, followed by the assurance function. According to a study, maternity wear was a way for many pregnant women to celebrate their bodies and make them feel confident. It wasn't merely a technique to hide their bodies.[5] Maternity clothes are vital for the mother's feelings as well as the unborn baby's comfort.[6]

Antimicrobial and eco-friendly maternal intimate gear is becoming increasingly popular among modern consumers. Antimicrobial technology is used to establish a long-lasting defence barrier against odour-causing bacteria, mould, and fungus. This also helps to keep the product fresh for longer time and boosts the wearer's confidence. In addition, numerous manufacturers are developing environmentally friendly maternity intimate apparel for all phases of parenting. Organic cotton, regenerated polyamide, and polyester fleece are among the materials used in multipurpose intimate apparel for pregnancy and breast feeding. Thus, during the forecast period, increased use of antimicrobial and eco-friendly maternal intimate apparel will fuel market expansion. [7] Anti-microbial finishes are used on maternity and post-maternity clothing to make them environmentally friendly and to keep feeding hygiene.[8]

Antimicrobial compounds are used on textiles to prevent the growth of microorganisms, the production of odours, and the deterioration of the fabric. Antimicrobial agents are typically applied to cotton fabrics in three main ways. 1. Ultrafresh NMV2: triclosan-based product 2. N9 pure silver: pure silver metal dispersion and 3. chitosan to generate antibacterial properties. [9]

N9 pure silver antibacterial and hygienic finish is one of them. It's a new particle silver-based technology that neutralises odour-causing germs on touch, keeping textiles fresher for longer. This ground-breaking technology provides superior odour management while also having immaculate environmental credentials and a high safety profile. In ultra-pure de-ionised water, N9 pure silver is a pure metallic silver. The amount of silver in each gram of N9 pure silver is extremely low. Despite the low silver content, the arrangement of the individual N9 pure silver particles makes them exceptionally effective at neutralising bacteria and other organisms. N9 pure silver does not leach. It stays put on the treated cloth and acts to keep bacteria and other germs at bay. This means that just a small amount of silver is released into the environment or onto the skin. [1]

II: Materials and methods

Fabric:

Fig 1: 100 per cent cotton cambric fabric

100 per cent cotton cambric fabric (Fig. 1), with following parameters is selected for the anti-microbial maternity wear.

Strength warp-106 N, Strength weft-117 N

Warp count- 61.7 Ne, Weft count- 58.9 Ne

Warp-100 Ends/Inch, Weft-82 Picks/Inch

GSM – 90, Weave - Plain

Design – yellow/black/off white print with base colour grey

Garment:

Fig 2 Maternity garment

Garment specification – Medium size flared kurta, relaxed fit with 3/4th sleeve, drawcord at waist, princess line silhouette and front zipper opening as shown in the Fig2.

Anti-bacterial finish: For maternity apparel, N9 pure silver was chosen as the antibacterial agent. It is a bacteriostatic, gently defensive, and freshness and odour control agent for textiles, particularly for maternity wear. It is safe on skin, does not leach due to its strong binding, and Oeko-Tex listed. Padding, exhaust, or dip-spin processes can be used to apply this finish to the cloth. The exhaust technique was used in this project.[1]

Technical Information of N9 pure silver: It is suitable for all fibre types, also safe for textiles with constant direct skin contact. The properties of N9 pure silver are listed below.

Chemical Nature: An aqueous suspension of Particulate Silver

Product pH (Direct): 8.5 to 13

Ionic Nature: Non – Ionic

Appearance: Deep Blue Colour

Solubility: Dispersible in Water

Stability: N9 pure silver is not sensitive to electrolytes and stable to diluted acids

Storage Stability: N9 pure silver is stable for 6 months when properly stored in closed containers at 200C - 250C.

Compatibility: Generally compatible with other textile chemicals such as softeners, OBA, silicones, fluorocarbons & other finishing products. Due to the huge number of different products available in the market, preliminary trials are recommended.

Ecology/Toxicology: The usual hygiene and safety rules for handling chemicals should be observed in storage, handling and use.

Application: The application quantity of N9 pure silver was used according to the type of the substrate-cotton, with longer wash durability requirement.

Add on: 0.3 to 1.5 per cent

Bath Preparation: N9 pure silver is added as the last component to the prepared bath undiluted and unfiltered.

Bath pH was maintained at 6 to 6.5 by using acetic acid/core neutralisers before adding N9 pure silver to the bath.

Single component and does not require any binder.

N9 pure silver fixes effectively on fibres simply by drying and additional curing is not mandatory.

In exhaustion process, N9 pure silver was added as last component to the prepared bath. Softeners and other finishing agents can usually be applied in the same bath along with N9 pure silver.

Application Technique:

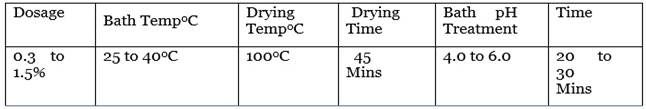

Exhaustion method: The flow diagram of the exhaustion method used to apply N9 Pure Silver on fabric is shown in Fig. 3 and the control parameters of the process are given in Table 1.

Fig. 3 Stages of exhaustion method

Table – 1 Anti-bacterial finish by exhaustion method parameters

The exhaustion was carried for 20 to 30 mins and after completion of the process it was ensured that the garment piece got uniformly wetted.

Hydro-extract process done prior to tumble dry in such a way that minimum 80 per cent pick up to be maintained in the garment.

As N9 pure silver alone was used, the suggested temperature to dry the garment in tumble dry was 1000C/45 mins.

The bath pH was not allowed to exceed >7 (alkaline) to avoid instability of chemical bath.

III. Results and Discussion

Evaluation of anti-microbial finish:

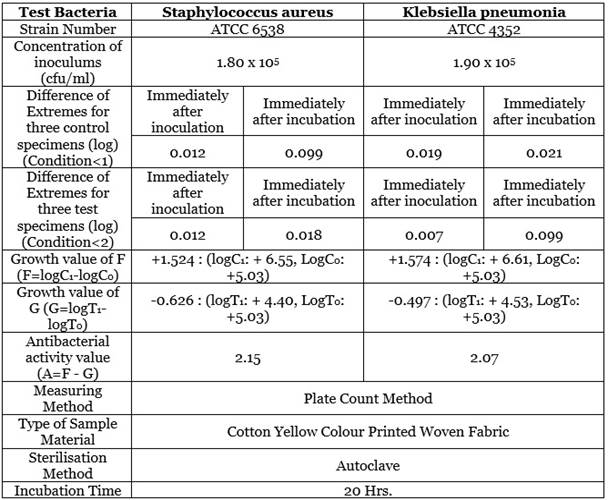

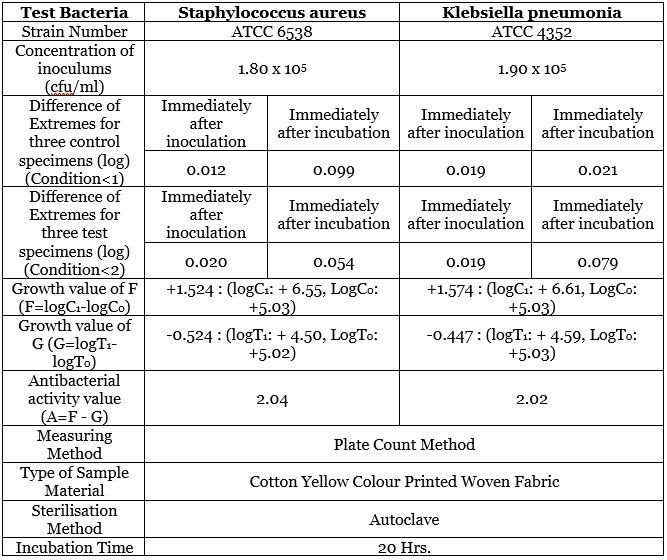

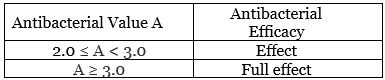

The Japanese Industrial Standards (JIS) L 1902:2015 technique, titled "Testing Antibacterial Activity and Performance on Textile Products," was used to assess the efficacy of N9 pure silver's antibacterial finish. Over a 20-hour period, it is designed to examine the capacity of fabrics treated with antimicrobial chemicals to limit microbial development and kill microorganisms. There are three sorts of tests in the official standard method: one qualitative and two quantitative. The qualitative method, known as the "Halo Method," is similar to the Zone of Inhibition but differs in a few ways, such as applying inoculum to molten agar and allowing it to solidify before putting the test piece to the surface. [8] The "Absorption Method," one of the two quantitative procedures, was employed to evaluate the samples in this investigation. The bioactivity was measured using a reference control sample that had no antibacterial characteristics. As per a study done, in the gram-positive bacteria, Staphylococcus aureus, Coagulase-negative staphylococci, Enterococcus, Streptococcus pneumonia accounted for 32.85 per cent, 40.39 per cent, 12.41 per cent and 10.22 per cent, respectively. [10] So, the anti-microbial property was tested with bacteria Staphylococcus aureus and Klebsiella pneumonia on N9 pure silver treated fabric samples. The treated samples divided as unwashed and washed for 20 times to access the lasting effect of the finish on the maternity wear. The number of bacteria, still living after an opportune contact time, is counted. The result of the test conducted on unwashed and after 20 washes are given in the tables 2 and 3 respectively. Table 4 shows the anti-bacterial efficacy guideline.

Table 2 – Test result of N9 Pure Silver treated sample with 0 wash

Table 3 – Test result of N9 Pure Silver treated sample with 20 washes

Table 4 – Anti-bacterial efficacy guideline

Based on the guidelines, both unwashed and washed sample maternity wear fabric treated with N9 pure silver are showing effectiveness in both anti-bacterial activity values in the range of 2 to 3 in combating the bacteria Staphylococcus aureus and Klebsiella pneumonia.

IV Conclusion

Anti-bacterial treatment for textile materials used to produce maternity wear is necessary to avoid cross infection by pathogenic micro-organisms, control the infestation by microbes, arrest metabolism in microbes to reduce the formation of odour and to safeguard the fabric from staining, discolouration and quality. N9 pure silver finished fabric has shown the efficacy in combating the common bacteria and proved to be having ability to provide protection from micro-organisms to the wearer of the maternity wear during maternity as well as nursing period.

Comments