International Labour Organization (ILO) defines productivity as the ratio between “output of work” to “input of resources”. Productivity is directly connected to the use of available resources. This means productivity will reduce if the resources are not utilised correctly. On the other hand, productivity is linked to the creation of value. This indicates high productivity will be achieved when activities add more value to the produced products.

Furthermore, the opposite of productivity is waste, which must be eliminated to improve productivity. Different people view productivity differently. For an economist, productivity is the ratio of output to input. For an accountant, productivity can be measured in financial ratios and budgetary variances. For behavioural scientists, productivity will be in labour utilisation (man days), and for engineers, productivity will be in capacity utilisation, production per man-hour or manpower efficiency. So, many productivity measures are available in an organisation, and people get confused about understanding how to measure the productivity of an organisation.

Most companies worry about efficiency rather than productivity. It can be defined as growth in the net output due to changes in efficiency and technical changes. The most common mistake a company does is to use productivity synonyms to measure productivity, which refers to the amount of a product or services produced. As a result of this confusion, people tend to believe that increased production means increased productivity. This is not necessarily true. Productivity is a relative concept, meaning it cannot increase or decrease unless a comparison is made over time. These five relationships can improve productivity:

• Output and input increases, but the increase in input is proportionally less than the increase in output.

• Output increases while input stays the same.

• Output increases while input is reduced.

• Output stays the same while input decreases

• Output decreases while input decreases even more.

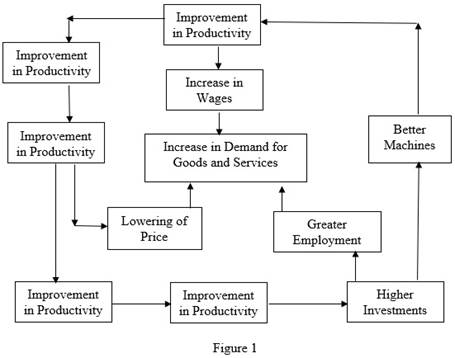

Productivity reduces the per unit manufacturing cost by effectively utilising all the resources and reducing waste. Lower per-unit cost means an increase in profit level. The organisation can again reinvest the surplus capital to expand its business, thereby generating further employment and increasing employee wages, which improves their purchasing power. The productivity increase can carve a pathway for a better economy. Figure 1 explains the same.

Today garment manufacturing organisations are under tremendous pressure to rapidly introduce new products as the product life cycle is becoming shorter. Because of inherent differences in the style and fabrics used, combined with numerous manufacturing processes, increasing requirements for quality, uniqueness, and individuality of garments, as well as the need to shorten manufacturing and delivery-time and reduce costs, manufacturing activities planning plays an essential part in achieving a position within market competitiveness.

The factories turned towards productivity to increase the profit margin and reduce the manufacturing cost. Machine and labour productivity increase when organisations produce required/ more quantity with the existing resources.

Any job contains two components: effective work content and ineffective work content. Effective work content or effective time is the basic work content required to produce that product. Ineffective work content or ineffective time in that activity consists of work content due to poor design of a product, work content by ineffective method of manufacturing, work content due to shortcoming of the management, and work content due to ineffective workforce.

Ineffective work content due to poor product design consists of bad product design, lack of standardisation, incorrect quality standards, and design demands the removal of excess material. This can be reduced by product development and value analysis. By setting up specialisation and standardisation, an organisation has to do market research, consumer research and product research before designing a product.

An ineffective management method consists of the wrong machine used, process not operated correctly, wrong tools used, bad layout causing waste movement, and operative’s bad working method. This can be reduced by effective production planning, which ensures a correct selection of machines, tools and equipment and ensures correct operational procedure.

Ineffective work content due to the shortcoming of management consists of excessive product variety, lack of standardisation, design changes, bad planning, lack of raw material, plant breakdown, plant in bad condition, and frequent accidents. This can be reduced by creating marketing and specialisation to minimise the idle time due to extensive product variety, and by improving the working condition to enable workers to work steadily. It will also reduce the ineffective time due to accidents.

Ineffective time within workers’ control consists of absence, lateness and idleness, careless workmanship and frequent accidents. This can be addressed through sound personnel policy and incentive policy that helps reduce absenteeism and carelessness. There is also the need to conduct safety training, which will reduce ineffective time due to accidents.

To improve the productivity of the garment industry, various techniques can be used depending on the production system of the organisation. Following are a few ways to improve productivity:

1.R&D for garments: Research and development in garments during the sample development help ensure the best utilisation of machineries and work aids during the mass production stage. It will also help to identify and plan the skill requirement.

2. Motion study: Conducting a motion study will help standardise the method of performing a task and correcting faulty motion by the operator. If the motion study is combined with Method Time Measurement (MTM) based software, the precise Standard Allowed Minute (SAM) can be calculated.

3. Ergonomically designed workplace: Ergonomically designed workplace improves the interaction of man and machine. This implies considering the operator’s safety and designing a workplace to minimise the material handling, thus reducing the operation cycle time.

4. Use of work aids: Guides and folders are devices that facilitate the operator to perform his task effectively with less effort. It also helps in maintaining a consistent stitching quality.

5. Reducing change over time: To minimise the style change over time, the SMED principle must be implemented. The internal activities (which can only be done when the machine is stopped) and external activities (which can be performed when the machine is running) need to be identified and try to convert internal factors into external factors.

6. Layout with minimum travelling: A method study needs to be done to identify the best possible layout, which reduces the transportation time. The best line layout needs to be identified according to the product categories.

7. UBT sewing machine: Using the auto trimmer sewing machine helps to reduce the substantial thread wastage and the cycle time, which will increase the quality and production capacity.

8. Line balancing: Line balancing aims to maximise operator utilisation and reduce bottlenecks considering the available skill matrix of the workers. In the balance line, the flow of the work is smooth, due to which there is no waiting time. It helps equal work distribution among the operator in a line and prevents over-production.

9. Required feeding of sewing line: Fault-free and precise cutting need to be done so that required feeding need to be achieved in time. To prevent over-production at different stages of production Kanban system can be implemented.

10. Real-time data: For prompt action on a shop floor, different types of real-time information is required, such as hourly production, line balancing, absenteeism, WIP (work in progress), bundle tracking, quality performance of the line, breakdown, etc. Corrective action needs to be taken as early as possible. Otherwise, the affect increases as time goes on.

11. Quality check points: Repair and rejects lead to significant productivity loss in a garment manufacturing setup. To check this, SQC (statistical quality control), Andon, and inline quality inspection need to be installed.

12. Training of supervisors: Supervisors are first-line managers, so they must be trained to develop soft skills and communication skills. They must be trained in fundamental management skills and they need to understand the fundamentals of industrial engineering like Operation Bulletin, skill matrix, layout, capacity study, line balancing, throughput time, etc.

13. Training of operators: Operators are the most valuable resource in the garment manufacturing industry. Organisations need to understand that training is not a cost but an investment. Training of the operator increases the operator’s skill level, which increases the line output and reduces the cost of quality.

14. Operator motivation: Operators are a crucial part of productivity improvement. Employee motivation generally depends on various factors like work culture, HR policies, fringe benefits, working conditions, etc. In garment manufacturing, operator motivation comes from extra reward, so certain incentive schemes must be devised for their extra effort.

Comments