Denim is one of the most common fabrics used in today’s world. Since huge volumes of denim jeans are produced and consumed annually, the environmental concerns associated with their production are also very high. However, the increased awareness of textile recycling has paved the way for using recycled materials in denim production.

The global denim market has seen persistent growth in the past few years, and is forecast to reach $107 billion by 2023. The increase in casual wear and availability of cost-effective and durable jeans has contributed to this growth. Over the years, brands have also reinforced the concepts of responsible production and launched environmentally friendly and sustainable collections.

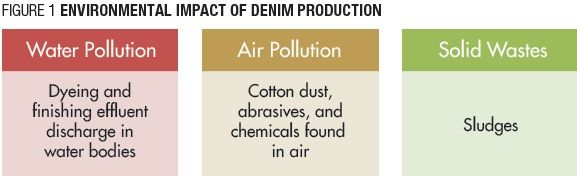

According to a study, approximately 2,900 litres of water, along with huge volumes of chemicals and energy, is consumed in the production of a single pair of jeans. When it is scaled up to the number of jeans produced globally, the environmental impact ranges from wastewater discharges to harmful gas emissions. The indigo dye used in denim production makes the water in the textile effluents toxic and harmful for consumption. This also creates an imbalance in the aquatic ecosystems. In addition, the usage of synthetic and chemical dyes results in serious environmental concerns like water pollution, air pollution and solid wastes, as shown in Figure 1.

Washing is done on denim fabric to improve the touch and feel experience of the fabric, and also for giving it a faded appearance. The abrasion of pumice stones used in the process leaves powdered particles in the liquor and the garment. Huge volumes of water are required for repeated washing cycles to remove the deposits. The effluent leads to pollution. Sandblasting is also done for giving the faded look, which uses silica. The silica dust thus released in the air causes severe respiratory diseases. Chemicals, such as hypochlorite or potassium permanganate, which are used in washing are harmful to the environment. Though some issues are associated with denim processing, a number of effluent treatment processes are applied for the same as well. Lately, however, a great number of denim brands are trying to adopt sustainable practices throughout their supply chain.

It is well established through several studies that the textile and apparel industry creates a significant environmental footprint. The industry generates enormous volumes of waste that pose resource challenges for future generations. To handle such challenges, brands offer takeback of used clothing from consumers. However, research shows that less than 1 per cent of this collected apparel is recycled. 80 per cent of this volume is sold as second-hand apparel in poorer countries, and nearly 20 per cent goes to landfill or are incinerated. Denim holds a substantial share in this waste generation. Studies indicate that 2.16 million tons of waste is generated from jeans annually. Even in EU countries where infrastructure for collecting old clothes exists, only 35 per cent to 50 per cent of this volume is collected back for recycling.

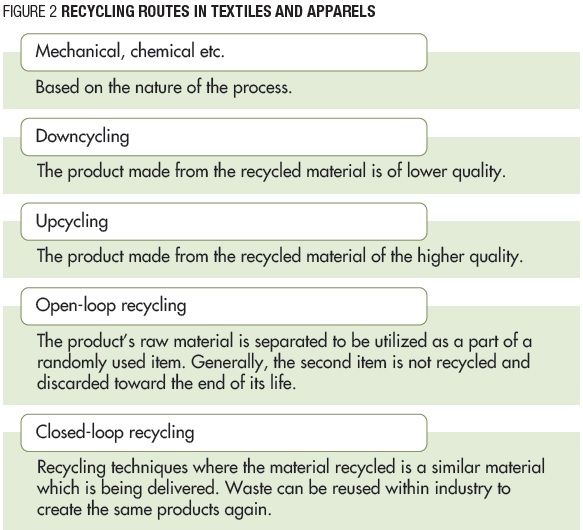

Cutting waste from jeans production contributes to about 10 per cent to 15 per cent of the waste generated. This waste is recycled mainly by unravelling and shredding it back to fibres. This is relatively easy due to its homogeneous material content. The used jeans that are discarded also contribute to the waste. However, the variation in colour, fabric contents and the usage of trims like zippers, buttons, labels etc, makes it difficult to recycle. The collection of used apparel is also a challenge in most countries. Textiles and apparel are recycled in a number of ways. Figure 2 shows the different types of existing recycling processes in this industry.

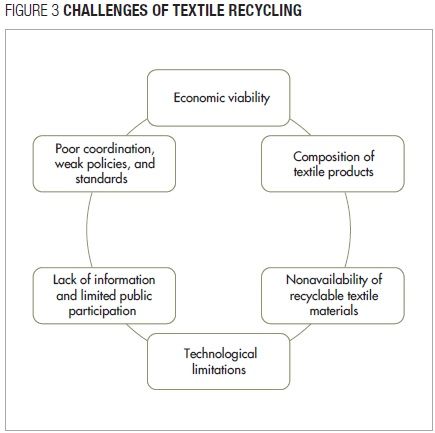

However, as shown in Figure 3, there are several challenges that are associated with the recycling process of textiles and apparel.

In addition, there are certain challenges and constraints that are specific to denim recycling. The collection and sorting of old jeans is a manual process and is extensively time-consuming. The trims used in the garment, like metal buttons, rivets and zippers, need to be removed with care before shredding. The labels are more difficult to remove as they are sewn onto the jeans. Often labels that are not removed are shredded along with jeans and contaminate the batch as these are made of a different material. One of the very specific features of jeans is the flat and fell inseam. These seams are thicker than regular seams and pose problems in shredding and carding. Most jeans nowadays provide a stretchable feature. The presence of elastane in the fibre content is another challenge. The colour variation in the recycled jeans creates a multicolour yarn that is difficult to dye. The recycled fibres are generally coarse due to their shorter span and hence are not comparable in quality with the virgin material.

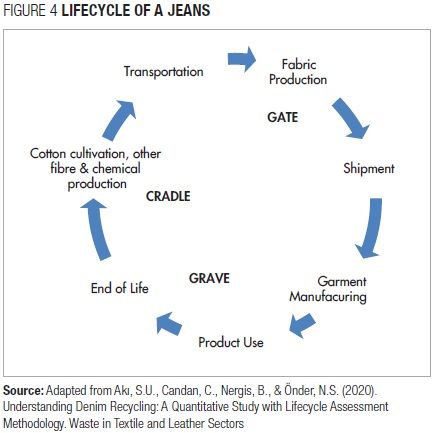

The environmental impact of denim is estimated by analysing the different phases of the lifecycle of the product. Identifying the phases with highest concerns and taking necessary measures will eventually reduce the overall environmental impact. The environmental performance of a product, when evaluated from raw material extraction to end of life, is called Life Cycle Assessment or LCA. Figure 4 shows the lifecycle of jeans.

Denim is a magic that has mesmerised the global market for a very long time. Fashion history has shown many changes in styles and silhouettes of jeans. Currently, all stakeholders of the apparel supply chain are working towards the cause of sustainability and recycling. A number of research and developments are targeted to tackle the issues associated with denim recycling. Brands are taking an effort to close their supply chain and encourage consumers to exchange their old jeans for new ones. Compostable jeans are also being produced without the usage of polyester threads and trims made of metal. Government legislation and support are also directed in managing waste, and regulations are being made for environmental protection. Retailers like H&M are raising customer awareness through their take-back programmes. Consumer awareness and contribution towards sustainability has increased the rate of recycling. The good news is that for a number of brands, the focus has moved towards lean manufacturing with minimum waste and converting the waste to recycled products to achieve a zero-waste economy.

Comments