Sedo Treepoint is taking part in India ITME, to be held at India Expo Centre & Mart in Greater Noida from December 8-13, 2022. The global trend is towards saving energy, increasing efficiency, and delivering high quality while reducing costs. Therefore, intelligent solutions are needed to help identify the current state and reduce resource requirements. In hall 1 at booth B5, Sedo Treepoint is presenting its products around the smart factory and intelligent manufacturing for dyeing and finishing plants.

Sedo Treepoint provides controller and software solutions which are perfectly matched to each other. The communication between the systems runs smoothly and contributes to a smart factory.

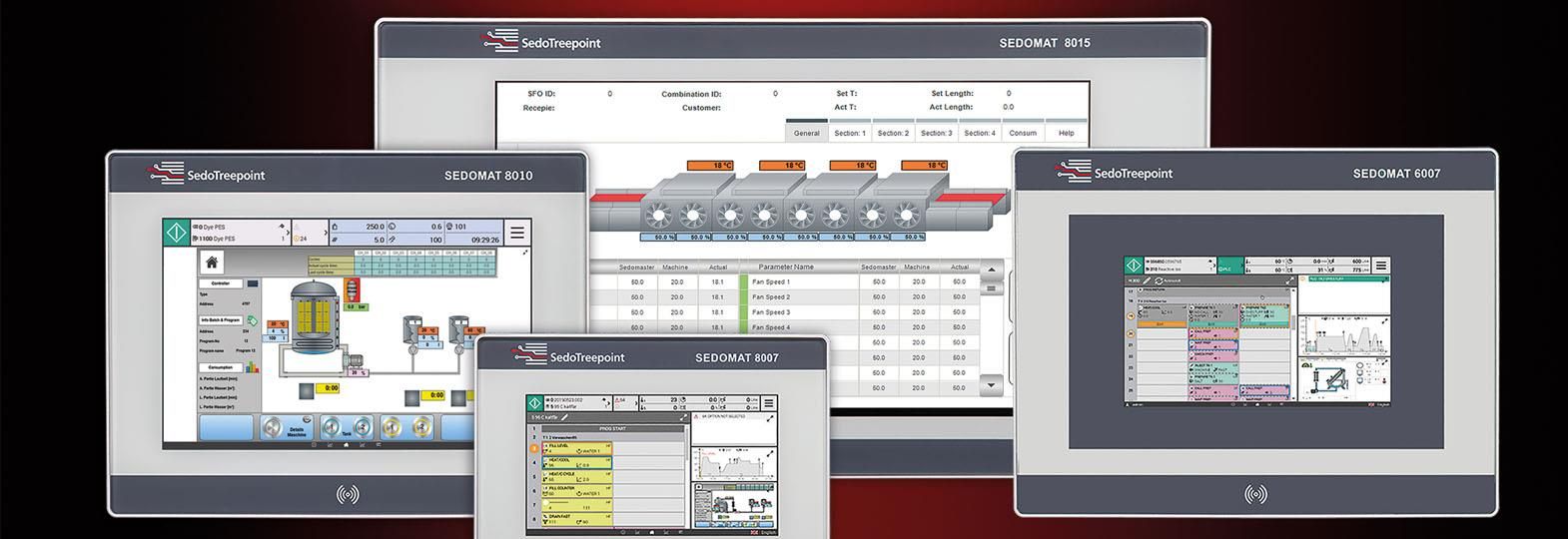

The Sedomat 6000/8000 controller series comes in four different variants and is the ideal choice for every type of dyeing and finishing machine. Through the high number of internal and external inputs and outputs, it can be adapted easily. The new series is highly flexible and offers different interface options like CANopen, Profibus DP and MODBUS RTU. To improve the communication between different systems, OPC UA and MQTT interfaces are used for data communication.

SedoMaster is the core of the production shop floor. Central production planning, control, monitoring, and reporting becomes available. It is a powerful tool for all key operators and the management due to the connection of all dyeing and finishing machines. The Reporting tool gives information on productivity, resource costs and OEE. SedoMaster also links all periphery systems like dispensers, dissolvers, or ERP system.

ColorMaster is an expert system for recipe management and colour measurement. The Windows based software calculates the best and most cost-effective recipe. In laboratory as well as in production, it offers the ideal treatment and correct dye programme selection. Colorimetric control within different production steps and calculation of additions for addition treatments supplement its functionality. These optimised workflows influence and optimise the consumption of the resources used.

EnergyMaster collects the energy consumption of the whole factory and supports in optimising the energy use, i.e., electricity, gas, compressed air, water, and steam consumption are target for further analysis. Together with the production data, reports can show the usage per metre, kg, etc. Optimisation results in a better carbon footprint and saves a lot of costs.

Sedo Treepoint systems offer many innovative features for smart factory and together with intelligent software solutions the complete textile supply chain becomes intelligent in terms of production. All solutions help to improve sustainability and reduce costs, while increasing productivity and efficiency.

Comments