Lotus fibre is a highly sustainable material that is completely natural and biodegradable. Unlike many synthetic materials that are used today, lotus fibre does not harm the environment and is completely renewable. Additionally, lotus fibre is incredibly durable and can last for decades without deteriorating. There are many species of lotus but Nelumbo nucifera lotus submerged in the water are ideal to extract strong and durable fibre. This fibre-producing lotus plant grows in India, China, Bhutan, Indonesia, Japan, Korea, Malaysia, Nepal, New Guinea, Pakistan, Philippines, Russia, Sri Lanka, Thailand, Australia, the US etc. It is a sacred plant in many cultures and is often associated with purity and enlightenment.

Fibre Extraction Process

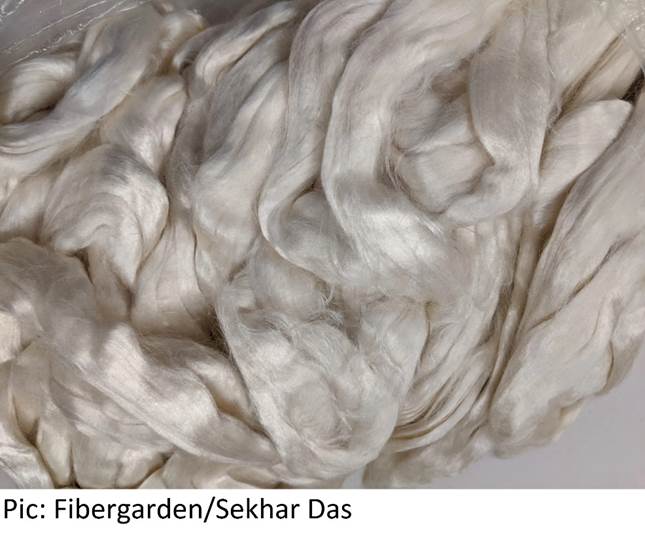

Lotus fibre is extracted from the stem of the lotus plant and has become increasingly popular in recent years due to its sustainability, versatility and durability. The lotus plant has a stem that is composed of long, slender fibres that are known for their strength and durability. The process of extracting lotus fibre is a painstaking one that requires a great deal of skill and patience. First, the stems of the lotus plant are harvested and then cut into thin strips. These strips are then soaked in water for several days to soften them and make them more pliable. After the strips have been soaked, they are carefully separated into individual fibres using a small tool known as a spindle. This is a time-consuming process as the fibres must be separated without breaking them. Once the fibres have been separated, they are then spun into thread using a spinning wheel or a hand spindle. The resulting thread is then woven into fabric using a traditional loom.

Fibre Property

1. Diameter: Lotus fibre is multi-filament structure, with a diameter of around 6 to 8 microns.

2. Length: The length of lotus fibres can vary, but they are typically around 15 to 20 cm long.

3. Colour: Lotus fibre is naturally creamy white in colour.

4. Cross section of fibre: It is generally round or oval.

5. Breaking tenacity is 3.44 cn/dtex, Initial modulus is 146.81 cn/dtex, Elongation at break is 2.75%.

6. Crystallinity index is 62.

7. The moisture regain is around 7%.

8. Thermal properties: Lotus fibre has good insulation properties, keeping the wearer warm in cold weather and cool in hot weather.

9. UV resistance: Lotus fibre has natural UV resistance, providing some protection against the sun’s harmful rays.

Use of Lotus Fibre

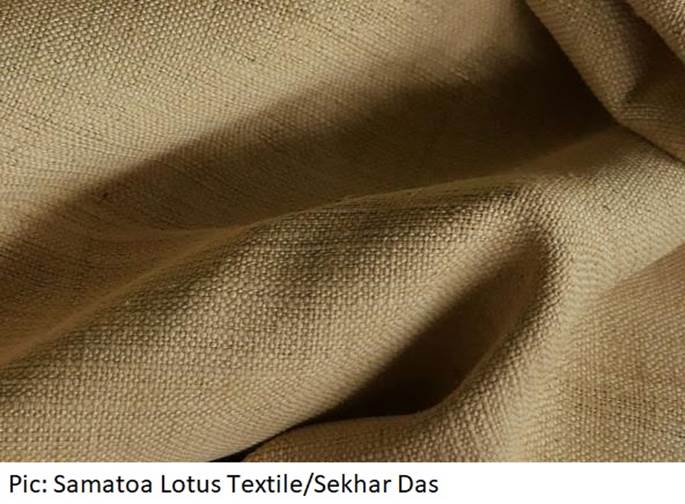

Textiles: Lotus fibre is used to make high-quality textiles, including clothing, scarves, and shawls. The fabric is lightweight, breathable, and has a soft, silky texture.

Cosmetics: Lotus fibre is used in some cosmetic products, such as face masks and lotions, due to its antioxidant and anti-inflammatory properties.

Conclusion

Lotus fibre is a unique material that has been used for centuries in different parts of the world. This natural fibre is incredibly sustainable, durable and versatile, making it an ideal material for a wide range of applications, from clothing to household items to high-end fashion accessories. Due to the labour-intensive nature of the process, lotus fibre is considered a luxury material and is often more expensive than other textiles. However, its sustainable and natural properties make it a promising alternative to synthetic fibres in the fashion industry.

Comments