We expect the government to provide impetus to become $350 billion industry by 2030

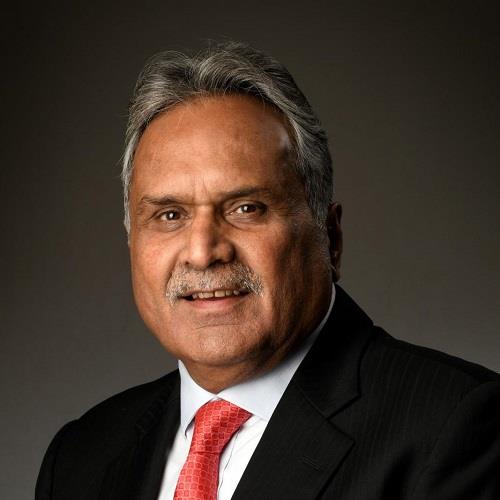

The Confederation of Indian Textile Industry (CITI) is the only national association that covers the entire spectrum of the textile and clothing industry spanning domestic and exporting units, including regional and sectoral associations from farms to garments and even textile machinery. CITI has signed MoUs with 13 major international textile associations for the promotion of textiles trade and investment. It, directly and indirectly, serves an industry that connects to millions of farmers, 100 million plus workforce, and 1.3 billion consumers. The cumulative annual turnover of CITI members is more than $30 billion. In view of the Narendra Modi-led National Democratic Alliance (NDA) government beginning its 3rd term, Fibre2Fashion spoke to Chairman Rakesh Mehra about the challenges and what the government can do for the country’s textile and apparel industry.

What are the major challenges before the new government, in terms of India’s textile and apparel industry?

After achieving its highest-ever exports of $43.4 billion in 2021-22, the Indian textile industry was witnessing a stagnation in domestic demand as also declining exports since then. However, the current financial year has started on a good note with India’s exports of textiles and apparel (T&A) registering a growth of 5.34 per cent in April-May 2024 as compared to April-May 2023. With the new government, the textile industry is looking forward to having policies towards raw material availability at competitive prices, checking rising imports, improving infrastructure, adoption of sustainable technologies, and improving ease of doing business. Such policy measures will not only help the industry in maintaining this growth trajectory but will also provide impetus towards achieving the visionary target of $350 billion market by 2030.

Majority of textile-apparel businesses fall under the MSME sector. To enhance liquidity for MSME entities, the government has amended Finance Bill 2023, wherein buyers (enterprises) are obligated to pay micro and small suppliers within 45 days. However, this has dampened sentiments in the trade of yarn and other products of textile sector. What do you think the new government should do?

The introduction of section 43(h) in the Finance Bill was to safeguard the interest of the MSME which fulfils the bulk of the industry requirements of various products and services. The traditional credit cycle in the Indian textile industry is longer than 45 days. This abrupt change has been affecting the entire production planning & schedule, and hence the government should carefully evaluate its impact on the textile industry. It is requested that this law may be introduced in a more phased manner with a phased reduction in the credit period to give enough time to the industry to adapt to the changes.

Across the Western world, people are buying less but are purchasing quality products that meet strict regulatory and sustainability standards. So, countries that do not act fast and start producing goods that meet these standards will stand to lose. What steps should the government take so that the Indian goods meet the required standards?

Yes, there has been a shift towards quality products which the industry is also recognising. However, there has also been an increased focus on product diversification to align with various consumer needs that go beyond quality, for example, the growing need for sustainable products that meet all the quality parameters as well as the health and safety of the people and the planet.

Since the Western world is a major market for Indian T&A products, it becomes essential for the industry to adapt to these changing trends. Stringent quality compliance and technology shift are the two major focus areas where the government and the Indian textile industry need to work. The government is already working on designing and developing standards at par with the international quality standards. The industry may adopt to these standards to improve the quality of its products. As far as the technology shift is concerned, India is dependent a lot on foreign technology. There is a dire need for the government to promote R&D for the development of indigenous technologies in line with the requirements of sustainability – with proven efficiency in energy, water, and material optimisation.

A lot has already been going on in this regard. However, the government needs to create more awareness among the industry members on these upcoming requirements and make the industry future-ready. The government may also facilitate collaboration between the industry stakeholders and international organisations for sharing best practices and knowledge which can also facilitate the transition towards producing goods that meet global standards.

I am happy to share that to create awareness in the industry as also to recognise and incentivise the efforts made by the industry players toward sustainability, CITI has also started the CITI Textile Sustainability Awards. The 2nd edition of it was organised during the Bharat Tex 2024. The then Minster of Textiles commended CITI for its efforts and also awarded the winners across the 5 different categories. CITI is planning to expand the scope of these awards in the years to come.

Quality Control Orders (QCOs) on viscose and polyester fibre and polyester yarn became big hurdle for domestic textile industry as a non-tariff barrier. Industry says that they are losing not only export market but also domestic market due to QCO on raw material. Should the new government consider changing the policy to ensure quality through QCO of final products like garments rather than raw material to stop loss of business of value addition?

QCOs have been announced to improve the quality of the finished products. While the objective and intent of the QCO is praiseworthy, it is imperative to note that worldwide such mandatory quality compliances are top-down with standards being imposed on final products first while in India it has been introduced on the fibre/yarn stage first.

There are certain varieties of raw materials that are not available domestically either in terms of quality or in required quantity and the industry is dependent on imports for the same. Though the government has allowed provisions for the import of inputs that are subjected to mandatory QCOs by Advance Authorization (AA), SEZ and EoU units, however the same is for physical exports only and not allowed for intermediate supply.

The QCOs have affected the availability of raw materials which might also lead to the flooding in imports of the next products in the value chain such as fabric and garments which will affect the interest of the domestic manufacturers.

Therefore, there is a dire need to re-evaluate the policy regarding the QCOs. To meet its objective of having quality finished goods, QCOs should be announced starting from the garments. This approach would ensure that quality standards are maintained throughout the production process i.e. from raw materials to finished goods.

The earlier government (Modi’s 2nd term) had indicated that it wants the Indian textile industry to speak in unison and would prefer single representation on behalf of the entire industry. How likely it is that this will be a reality?

The Indian textile industry is diverse in nature with each segment having its own challenges and aspirations. However, the government has always visualised the textile industry as one and has always worked towards its holistic development. With this objective, the government has always requested the entire industry to speak in unison. With this objective in mind, the National Committee on Textiles & Clothing (NCTC) was formed in 2019 on the recommendation of the then Minister of Textiles. NCTC is a national-level platform of major textile export promotion councils, and important sectoral and regional textile industry associations and is facilitating the representation of the industry issues in a single voice. NCTC has been holding regular meetings and has been instrumental in undertaking research and policy recommendations capturing the expectations of its constituents. In fact, the 2nd meeting of NCTC for the year 2024 was organised in May 2024 where the members decided on the common policy measures to be requested to the newly formed government to enable the industry to overcome the present stagnation as also move towards achieving the visionary target of $350 billion industry by 2030.

Indian cotton has been branded Kasturi to increase its exports. Do you think the government should take steps to use more of Kasturi cotton to make products for exports, rather than exporting the raw material?

‘Kasturi Cotton’ is a commendable initiative of the government to enhance the global recognition of not just Indian cotton but the entire cotton value chain through enhanced traceability and improved quality parameters. It marks a new quality standard for Indian cotton-based textile products. The government is taking considerable steps for the promotion of Kasturi Cotton to ensure that the products made out of Kasturi Cotton can fetch a premium for the Indian exporters. In this direction, the government, in association with TEXPROCIL (The Cotton Textiles Export Promotion Council) and CCI (Cotton Corporation of India), has already rolled out a blockchain-based technology to enable the traceability of garments and fabrics made of Kasturi Cotton using a QR code that can be used to trace back up to the ginner. The industry is hopeful that as the demand of products made of Kasturi Cotton increases more farmers will engage themselves in its cultivation.

India’s cotton yield is very less compared to Brazil and the US. Is there anything the government can do to drastically increase the cotton yield, which could be a gamechanger for the country’s textile industry?

India’s cotton yield is significantly lower compared to the major cotton-producing nations. While countries like Australia, Brazil etc have been able to achieve yield as high as 2,000 kg lint/ha, India’s yield has been stagnated at just about 450 kg lint/ha since last few years which is even lesser than the world’s average yield of about 760 kg lint/ha.

Anticipating the increase in demand of cotton, the government has been working proactively towards increasing its production as yield. In fact, during the last year, both the Ministry of Agriculture and the Ministry of Textiles came together for the development of Indian cotton sector and announced a Pilot Project on Cotton across the major cotton-growing regions. The project was based on the CITI’s recommendation to the Ministry. CITI is one of the implementing partners for this project. The project has showcased that significant improvement in cotton yields can be achieved only by following better agronomics practices. For continued productivity improvement through such targeted interventions, the government may continue the project with increased area coverage, and also announce more such projects.

Technology Mission on Cotton (TMC) announced during 1999-2000 played a significant role in improving cotton productivity, which peaked at about 398 lakh bales in 2013-14 from levels of about 156 lakh bales in 1999-2000. However, since its closure, productivity has been declining with a cotton crop estimated to be about 325 lakh bales for the cotton season 2023-24. Considering the impact it created on cotton cultivation, the government may come up with the TMC 2.0 with a special focus on seed technology. TMC 2.0 can prove to be the real game changer for the Indian cotton industry.

Whether one likes it or not, Indian textile industry imports a lot or raw material from China. What steps should the government take to decrease imports, especially from China?

India is mainly importing MMF raw materials (fibre/yarn) from China mainly because of the following reasons:

- Cost advantage as compared to domestic suppliers as also other foreign suppliers.

- Domestic unavailability of certain specialised fibre/yarn categories in terms of required quality or quantity, e.g. bamboo fibre, solucell, FDY etc. Some of these raw materials are required in small quantities and hence there seems to be a viability issue of domestic manufacturing for such specialised fibre/yarns at the moment.

To prevent imports from China, the government needs to ensure enough domestic availability of all raw materials in the required quality and internationally competitive prices. For the same, there is a dire need for the government to improve the existing capacities’ cost competitiveness through various government schemes. It is also recommended to promote constant R&D in the sector to develop newer varieties of fibres/yarns for making specialised products with enhanced technical properties.

The new government is expected to continue negotiations for free trade agreements (FTAs). What additional things would you recommend the government to include in its negotiations, especially in FTAs with the UK and the EU?

Both the UK and EU are important markets for Indian T&A products. The current trade negotiations will give India better market access to these countries. However, apart from the duty tariffs and PSR (product specific rules), the government should also negotiate the various non-tariff/technical barriers that Indian exporters might be facing while exporting to these countries. Both EU and the UK are coming up with stringent quality measures, and at the same time, the Indian government through BIS (Bureau of Indian Standards) is also coming with standards that are at par with international norms. To facilitate the trade, both parties may also negotiate for mutual recognition of testing and quality norms which will further catalyse the trade between them. India may also negotiate for signing an agreement on an Authorised Economic Operator (AEO) Scheme which will reduce the logistic time between these countries by enabling faster movement of cargoes.

What are CITI’s expectations from the new government?

There are two major expectations of the industry from the new government:

- Better availability of raw materials at international competitive prices.

- TUFS-like scheme to revive investment in the T&A Industry, especially in the field of processing and value-added products.

Apart from the above, just before the elections, discussions related to various measures for checking rising imports, policies like PLI 2.0 with wider product coverage and lower threshold, as also trade negotiations with countries like EU, UK etc were going on. Since this is the 3rd consecutive term of the NDA government at the centre, industry is hopeful that all such policy measures and trade negotiations will soon be in place.

The industry is hopeful that under the continued leadership of Prime Minister Narendra Modi and the guidance of the Minister of Textiles Giriraj Singh many of the prevailing issues of the industry such as raw material availability at competitive prices, inverted duty, QCOs related issues etc will soon be resolved. We are also expecting that soon new schemes and policies will be announced for enhancing raw material production, capacity creation, strengthening processing sector etc which will catalyse the growth of the Indian T&A industry and propel it towards becoming the $350 billion industry by 2030.