China claims one-third in global textile machinery export market

The China Textile Machinery Association (CTMA) was established in May 1990. With 663 members, the association is a social and economic group comprising enterprises and institutions voluntarily organised by the textile machinery and equipment industry, and is a corporate legal entity approved by the ministry of civil affairs of the People's Republic of China. Vice-President Gu Ping gives a comprehensive overview of the Chinese textile machinery sector in an interview with Fibre2Fashion.

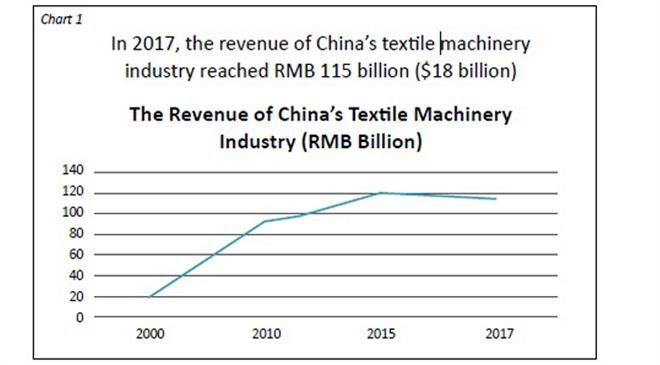

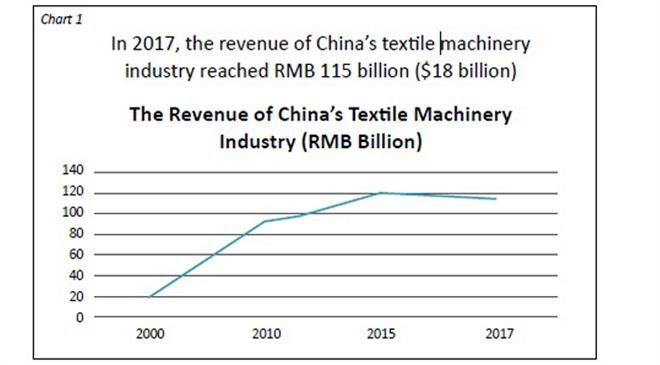

What is the size of the Chinese textile machinery industry? At what rate is it growing?

The figures are as shown in chart 1.

What is the share that Chinese manufacturers claim in the global textile machinery market?

China-made textile machinery constitutes one-third of the global textile machinery export market.

What is the annual export of textile machinery from China?

The export of textile machines from China was $3.4 billion in 2017, and $2.98 billion in 2016.

How does the ancillary industry work in China?

China produces over 600 kinds of machinery and ancillaries, including all for the textile sector. Also, China exported $0.62 billion worth of ancillaries in 2017 to the entire world.

Which regions are the machinery hubs in China, and what is the specialisation of each?

The south and east of China, such as Jiangsu, Zhejiang, Shandong, Fujian and Guangdong provinces are the hubs for the machinery industry. For example, around 80 per cent of circular knitting machines are produced in Fujian province.

Which are the major markets for Chinese weaving, spinning, cutting & stitching, and processing machines in textiles?

In domestic, south-east China is the major market. In north-west China, Xinjiang province has been becoming more important of late.

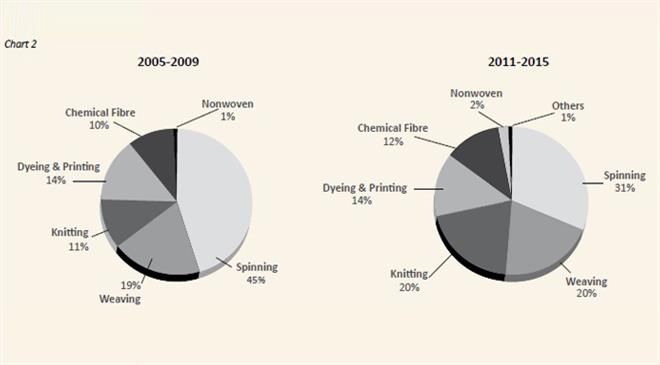

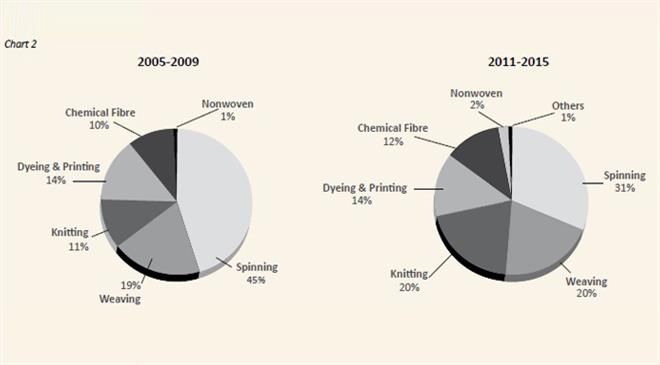

Where is the focus in textile machinery growing, and what kind of technologies are Chinese companies investing in?

The figures are as shown in chart 2.

What steps are being taken to ensure that both machinery and manufacturing result in a small carbon footprint?

Textile machinery enterprises have made great efforts in promoting technology innovations that suit the needs of the market. From national policy constraints to the promotion of environmental awareness in the industry, machinery companies have adopted more eco-friendly production technologies. For example, in recent years, with the rapid development of digital printing, the processing technology has become more mature; it reduces the cost of production, which in turn provides a good solution for environmental protection. Similarly, in spinning and weaving, there are innovative technologies for energy saving and emission reduction.

Labour costs are said to be going up. How is this industry dealing with this issue?

One of the trends in our industry is that innovation is focused on automation, intelligence, information and networking. For example, in the past, for a mill with a capacity of 10,000 spindles usually needed hundreds of workers. Nowadays, it needs around 30 workers.

What are the top 5 HR policies that the machinery owners follow?

Machinery company owners follow the Chinese labour law; the association does not set any guideline.

What types of machines or ancillaries does China import, and from where?

China can make all sorts of machineries or ancillaries. For certain types, China imports from Europe and Japan; such as for some types of needles.

How is the ongoing trade war with the US expected to hit business?

In the first round, the whole textile machinery industry was in the 301 list, but most sectors were removed from it. Therefore, it is good for our sector.

What is the nature of R&D in China? How does the government support and encourage R&D?

Most textile machinery manufactures are private companies, and innovation is very important for them. As per CTMA, 228 Chinese textile machinery companies gained 996 patents in 2011-2015.

What is the level of penetration of technologies equipped with AI and IoT in China?

Chinese textile machinery companies focus on innovation in these areas. Some products have achieved a high-level such as the printing sector; the pattern of printing and dyeing equipment has been applied by artificial vision detection technology.

What are the challenges that the Chinese textile machinery industry is facing?

Basic research for textile machinery is a weak point, such as the quality of raw material and machinery components that need to be improved. The innovation required to respond to the changing market needs to be further strengthened.

What are the future plans at CTMA? Any big events and initiatives planned this year?

We plan to continue to promote technological advancement in the industry and help companies develop in international markets. We organise events such as ITMA ASIA & CITME 2018 in Shanghai. Apart from that, our members will be attending an exhibition in Vietnam in November and in Myanmar in December this year. (HO)