Man-made fibre apparel account for approximately 78 per cent of the world fashion clothing market, as per the International Textile Manufacturers Federation (ITMF).

According to the Bangladesh Textile Mills Association (BTMA), the country’s spinning mills are starting to switch to manufacturing synthetic yarns. Some of the strong players of the industry have already invested in the establishment of new units for synthetic and blended yarns due to the rising demand from garment factory owners.

Noman Group, a major textile manufacturer in South Asia, is establishing a manufacturing unit for synthetic yarns with a capacity to produce approximately 100 tonnes of synthetic yarns per day. It is also constructing a unit for blended and cotton yarns with a capacity of 125 tonnes per day. The company has invested approximately Tk500 crore for the units and production is expected to start in October 2022.

Additionally, Envoy Group has planned to invest Tk125 crore in manufacturing about 12 tonnes of synthetic blended yarns per day. Matin Spinning Mills has invested Tk186 crore to produce synthetic yarn, while Maksons Group has planned to invest around Tk1,000 crore in three new spinning units in the Mirsarai Economic Zone. Square Textiles and Mozaffar Hossain Spinning Mills have invested approximately Tk30 crore and Tk250 crore, respectively. Presently, Bangladesh imports most of the synthetic yarns from China.

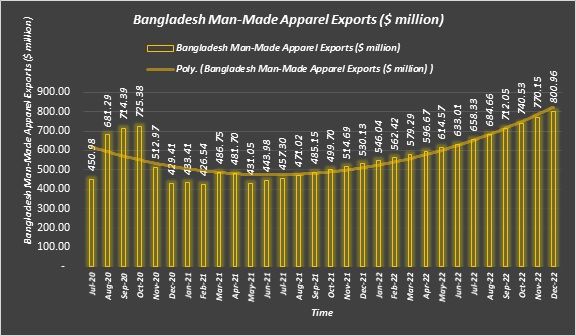

The monthly average of man-made apparel exports of Bangladesh was $585.74 million in H2 2020, which dropped significantly by 23.08 per cent to a monthly average of $450.57 million in H1 2021, according to Fibre2Fashion’s market analysis tool TexPro.

However, the number is expected to see a 9.42 per cent rise in H2 2021 to reach a monthly average of $493 million. In 2022, the monthly average is expected to surge by 33.51 per cent to touch $658.22 million.

Fibre2Fashion News Desk (KD)