Degda Corporation: Precision in spare parts for the shoe and garment industry

With over three decades of experience, Degda Corporation/Sewmech, under the leadership of Jitendra Degda, has become a trusted supplier of industrial sewing machines, cutting machines, leather sewing machines, and a wide array of spare parts. Specialising in spare parts for globally recognised brands like Juki, Brother, Pegasus, and Singer, Sewmech has built a reputation for ensuring a seamless production line for its customers.

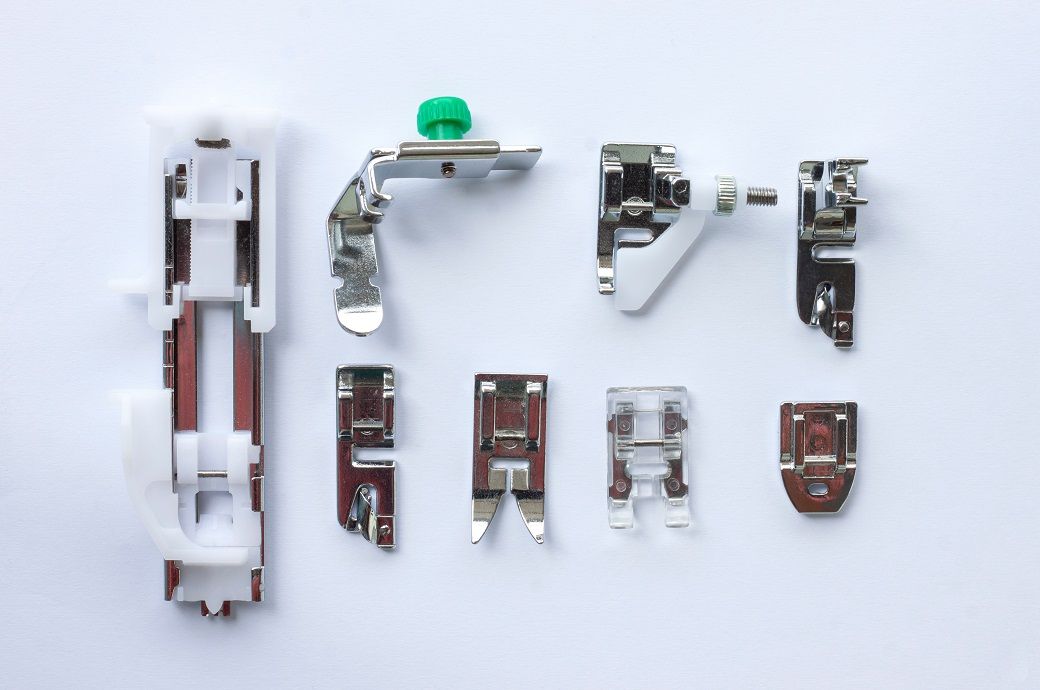

At GTE 2024, Sewmech showcased its extensive range of replaceable spare parts for sewing machines and shoe-making equipment. “We have over 4,000 pairs of parts with us, catering to the day-to-day needs of factories,” Jitendra Degda told Fibre2Fashion during the fair. While acknowledging that spare parts add to production costs, he stressed the durability and quality of the components, which ultimately ensures smoother operations for manufacturers.

Customer feedback was overwhelmingly positive, though Degda noted a higher number of student visitors than buyers this year. On the environmental impact, Degda highlighted that their steel parts do not contribute to environmental degradation, aligning with the industry’s growing focus on sustainability.

Aprameya Enterprises: Enhancing machine productivity with conveyor units

At GTE 2024, Aprameya Enterprises, led by director JK Sachin, showcased its conveyor units and accessories designed to boost productivity in garment manufacturing. “By adding our extra conveyor unit to small machines, manufacturers can increase production from 1,000 to 1,500 units per day, and with the attachment, production can rise up to 2,000 units per day,” Sachin told Fibre2Fashion.

Aprameya’s products are user-friendly, maintenance-free, and environmentally friendly. The feedback at GTE 2024 was overwhelmingly positive, and Sachin is optimistic about future business opportunities.

The company also offers strong after-sales support, including a one-year warranty and regular maintenance checks. “We train our customers on how to operate and maintain the conveyor units and accessories, with regular follow-ups every three months,” Sachin added.

Fibre2Fashion News Desk (RKS)