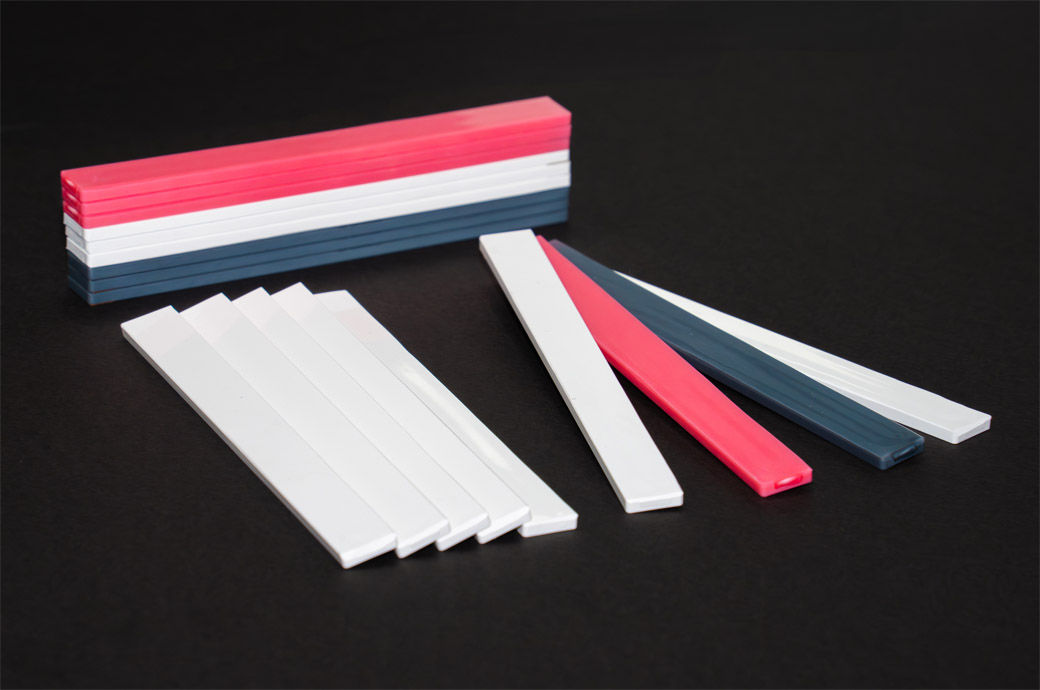

The V-0 rating is the highest level of flame retardancy performance in the industry, where the flame must self-extinguish within 10 seconds when the material is set on fire vertically. LG Chem is the first in the world to have been certified for V-0 flame retardancy performance with PFAS-free PC/ABS material.

With its own-developed special flame-retardant process, LG Chem has made its PC/ABS material more flame-resistant without PFAS. It also added PCR plastics to reduce carbon emissions. This PFAS-free material emits 46% less carbon compared to traditional PC/ABS materials as it contains more than 50% of recycled plastics.

PFAS is commonly used in cooking utensils, clothing, and cosmetics as it is highly flame-resistant and does not dissolve in water and oil. However, as it does not decompose in nature and has a negative impact on the environment, the demand for PFAS-free materials is growing mainly in Europe and the U.S.

“The transition to eco-friendly materials, including PFAS-free flame-retardant plastics, will become a global trend. We will continue our research and development efforts to create eco-friendly and flame-retardant materials that prioritize customer well-being and the environment,” said Steven Kim, Senior Vice President of LG Chem’s Engineering Materials Business Unit.

PFAS-free flame-retardant materials are expected to be applied in various electrical devices such as laptops and tablets – devices often in close contact with the human body and generate heat – and industrial equipment such as inverters and electric vehicle chargers. In addition to PC/ABS materials, LG Chem has successfully obtained UL certification for various PFAS-free flame-retardant materials it has developed, including PC and PBT.

Fibre2Fashion News Desk (RM)