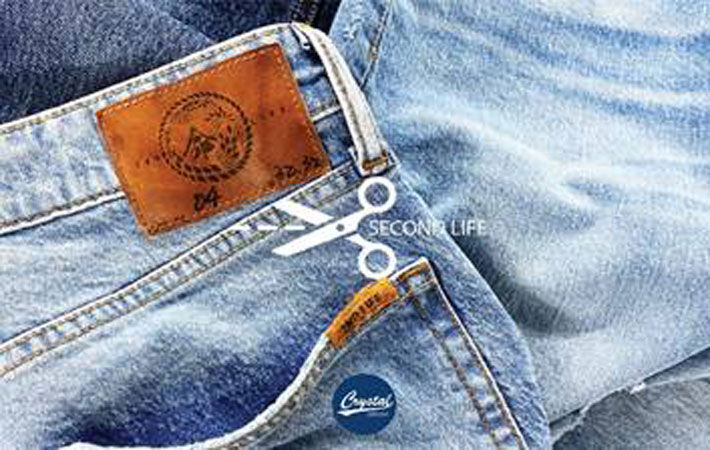

Crystal group has launched a new eco denim collection, Second Life online. The collection adopts recycled denim fabrics and sustainable materials to minimise wastage and keep materials in use, achieving a circular denim business model. Headquartered in Hong Kong, is a global leader in the apparel manufacturing industry, which serves major apparel brands.

The eco denim factory in China initiated the new concept, Second Life in 2020 and worked towards infusing pre-consumer cut waste and sorted scraps with a new life. By reducing the use of new materials, Crystal Denim can reduce water and energy consumption from growing new cotton, which accounts for around 70 per cent of water consumption and 10 per cent of carbon emission throughout the product life cycle of denim jeans. By collaborating with the partnering mills, Crystal Denim has successfully developed 10 denim fabrics for men and women collections, Crystal said in a press release.Crystal group has launched a new eco denim collection, Second Life online. The collection adopts recycled denim fabrics and sustainable materials to minimise wastage and keep materials in use, achieving a circular denim business model. Headquartered in Hong Kong, is a global leader in the apparel manufacturing industry, which serves major apparel brands.#

Compared with the traditional recycled denim fabrics, the fabrics of Second Life collection can provide greater depth of colour shade and stronger intensity of weft yarn while maintaining the durability. The variety of colour does not necessarily have to be sacrificed when using recycled materials. Ten fabrics are also different in recycled content, elasticity, and stretchability. With more choices of colour shade and different washing effects, the fabrics can create both dark and light colours, thus offering more styles and widening the product range. The collection goes for a vintage look to embrace denim authenticity. All fabrics are launched with physical and digital format, and benefit product development including 3D virtual sampling, Crystal said.

Crystal Denim is committed to producing cleaner jeans. The collection utilises recycled cotton which is dyed with liquid indigo for further water and chemical reduction. Some key wastewater parameters such as chemical oxygen demand COD and total suspended solids can be reduced over 60 per cent. Recycled denim fabrics can mitigate the environmental footprint of virgin denim fabrics production, particularly water consumption. Eco washing methods are adopted in the finishing approaches without manual labour work. The whole collection of closed loop denim made by recycled fabrics are certified with Recycled Claim Standard (RCS), as well as sustainable materials including Lycra T400 fibre with EcoMade technology and Repreve recycled polyester. With the chain of custody standards, certified materials are traceable along the supply chain. Upon scanning the QR code on the product, a customer can access to the video about this collection and manufacturing information, including fabric information, environmental impact measurement score, sample room and washing information, and certificate logo, according to Crystal.

“The collection goes beyond Second Life and extends the circularity to even Third Life by further regenerating the wastage from the circular fabrics to other denim items. The cut waste from Second Life denim is gathered and upcycled as the new kimono jackets, patches, and accessories to work towards zero wastage,” Miles Lam, assistant general manager of product development of Crystal Denim said.

Fibre2Fashion News Desk (GK)