Twinery, the innovation arm of MAS Holdings, recently signed a licensing agreement with the Colombo Science and Technology Cell of the University of Colombo to implement at the MAS Fabric Park a technology developed in Sri Lanka to use aluminium waste for treating textile industry waste water. The closed-loop model process converts the waste into bricks.

The research, funded by Twinery, was jointly conducted by the Colombo Cell and MAS.Twinery, the innovation arm of MAS Holdings, recently signed a licensing agreement with the Colombo Science and Technology Cell of the University of Colombo to implement at the MAS Fabric Park a technology developed in Sri Lanka to use aluminium waste for treating textile industry waste water. The closed-loop model process converts the waste into bricks.#

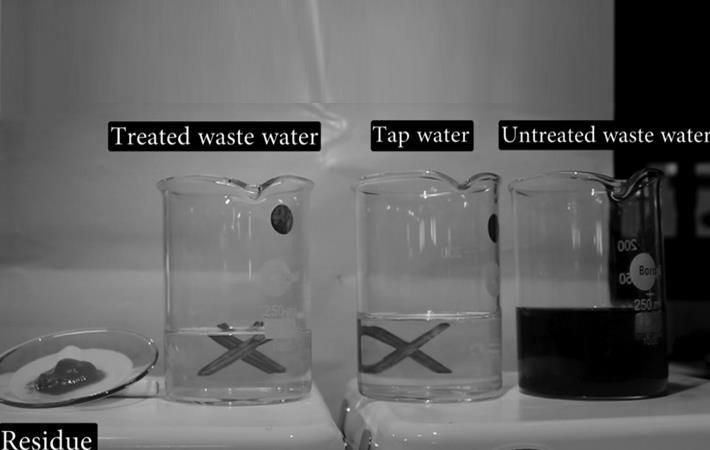

The idea was to convert sludge from the aluminium industry as a filter material to treat the waste-water from the apparel industry. The proof of concept for the technology was developed through a series of undergraduate research projects with minimal funding of rupees 16,000 in the department of physics. Even though this was an undergraduate research, the outcome was impactful, according to principal investigator Dilushan Jayasundera, senior lecturer in physics at the university.

Solid waste from aluminium anodizing industry is converted with minimal processing to remove colour from dye-containing waste-water, said Shashiprabha Vithanarachchi, consultant and senior lecturer in chemistry at the university.

The final brick was tested at the large-scale textile water treatment plant at MAS Fabric Park to ensure industry applicability, according to Sri Lankan media reports. (DS)

Fibre2Fashion News Desk – India