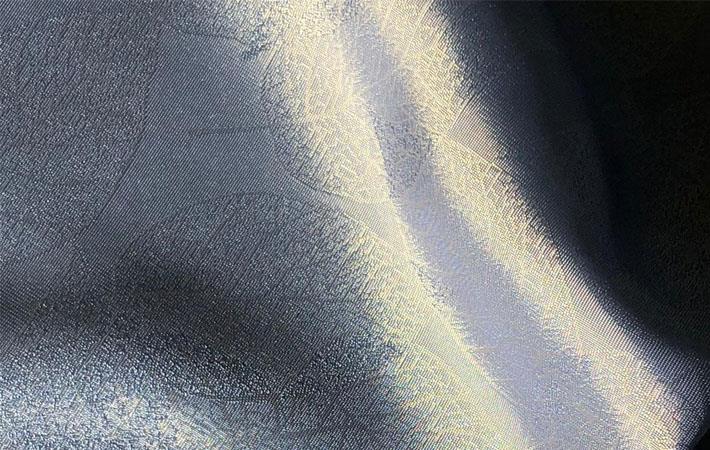

The Bemberg proposal will especially focus on Velutine Evo for shell fabrics, the new technically advanced finishing refinement technology developed in the Japanese laboratories of Asahi Kasei that offers a premium finish to the best qualities of the classic Bemberg peach skin touch. As part of the company’s continuous innovation, Velutine Evo brings better environmental, energy and water profiles for the benefit of Bemberg partners in the manufacture of their ranges. It sets a new benchmark for everyday luxury with a new generation of fibrillation technology.

And apart from the exquisite and precious touch of Bemberg fabrics, visitors at PV will see the unique circularity of Bemberg from its source, manufacture and end-of-life credentials, supported by the LCA study, signed by ICEA and validated by Paolo Masoni, confirming a new quality profile and standard with a more responsible and unique position today. Apart from full GRS certification, Oeko-Tex 100, ISO 14001, & Eco-Mark, Bemberg also has a new Compostability Certification.

The Innovhub-SSI report confirms that Bemberg filaments disintegrate at 100 per cent value within the limits specified by the UNI EN 13432, point A.3.1 for disintegration in composting. Also, a new Ecotoxicity metric to EN 13432:2000 Annex E, the compost obtained from the Bemberg filaments according to ISO 16929:2013, revealed no ecotoxicity effect. The Bemberg filaments were tested for heavy metals and other toxic hazardous substances and were found to comply with tests specified by the UNI EN 13432.

Fibre2Fashion News Desk (PC)