“If you walk out into the sunlight, you will get increasingly hot because your body and clothing are absorbing ultraviolet (UV) and near-infrared (near-IR) light from the sun,” said Andrew. “And as long as you’re alive, your body is generating heat, which can be thought of as light, too.”

To make people more comfortable outside, scientists have been developing textiles that simultaneously deflect the sun’s rays and push out natural body heat – a process known as radiative cooling. Some of those materials have light-refracting synthetic particles, such as titanium dioxide or aluminium oxide, embedded into spun fibres. Others use expensive organic polymers such as polyvinylidene difluoride, which require toxic per- and polyfluoroalkyl substances – PFAS, or ‘forever chemicals’. In each of these cases, production on an industrial scale is simply unsustainable.

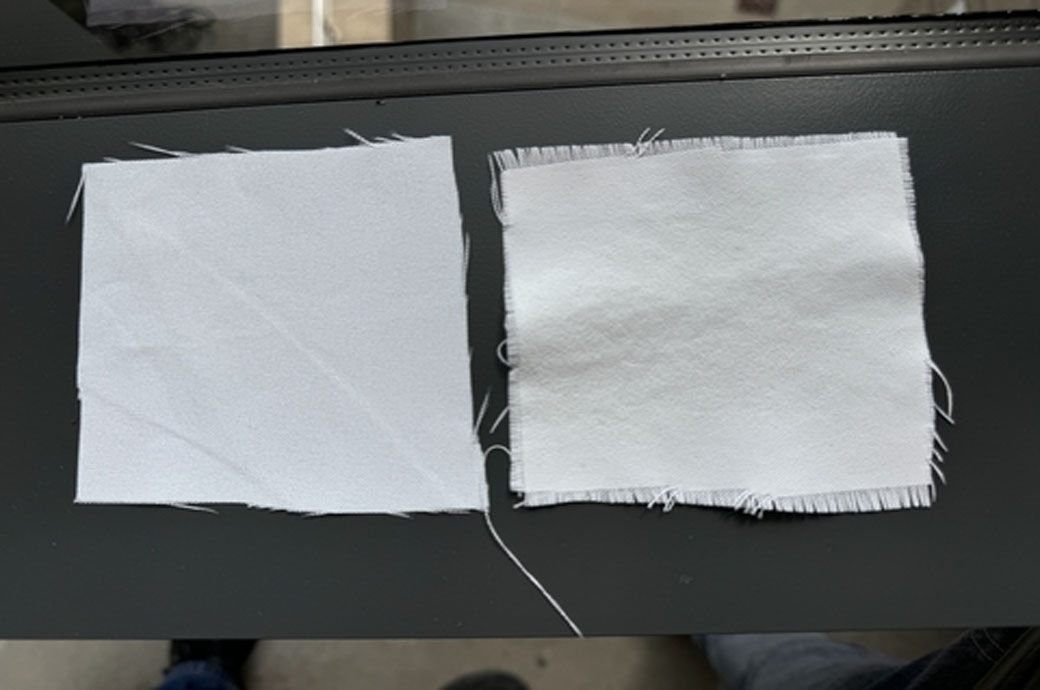

Inspired by the crushed limestone-based plasters historically used to keep houses cool in extremely sunny places, Patamia and Yee worked on inventing a method to integrate calcium carbonate – the main component in limestone and chalk – as well as bio-compatible barium sulfate onto a polymer coating, into a process that Andrew had previously developed called chemical vapour deposition (CVD).

The researchers tested the cooling abilities of their new fabric outside on a sunny summer day when the temperature soared to more than 90°F. They observed that the air temperatures underneath the treated fabric were 8°F cooler than the ambient temperature in the middle of the afternoon. When they compared their new fabric to conventional, untreated cloth, the difference was even greater: their chalk-coated sample was up to 15 degrees cooler than the untreated fabric, which heated the air underneath the sample.

“We see a true cooling effect,” said Patamia. “What is underneath the sample feels cooler than standing in the shade.”

“So far in our processes, we’ve been limited by the size of our laboratory equipment,” Andrew says, but she’s part of a startup company that’s scaling up the CVD process for bolts of fabric, which are about five feet wide and 100 yards long. Andrew explains that this venture could provide a way to translate Patamia and Yee’s innovations into pilot-scale production.

“What makes our technique unique is that we can do this on nearly any commercially available fabric and turn it into something that can keep people cool,” concluded Patamia. “Without any power input, we’re able to reduce how hot a person feels, which could be a valuable resource where people are struggling to stay cool in extremely hot environments.”

Fibre2Fashion News Desk (RR)