The Plant-Based 501 is made of at least 97 per cent plant-based materials, with all certified organic cotton, natural dyestuff, a plant-based patch, and ink made from wood waste. Hitting the market in late Summer 2023, these jeans are an indication of what the industry could look like in the years ahead given the push to minimise synthetic materials derived from fossil fuels and the need to make more garments with renewable inputs rather than finite resources. They are an evolution in the company’s design innovation practice, building on past seasons and establishing new foundations on which to build going forward, Levi’s said in a press release.

“As a company that has been making 501s for 150 years now, we have an opportunity—and a responsibility—to continually interrogate the process by which these jeans are made,” said Paul Dillinger, vice-president of design innovation at Levi Strauss & Co. “These jeans build on past efforts to create more circular jeans and in turn give us a foundation for future innovation.”

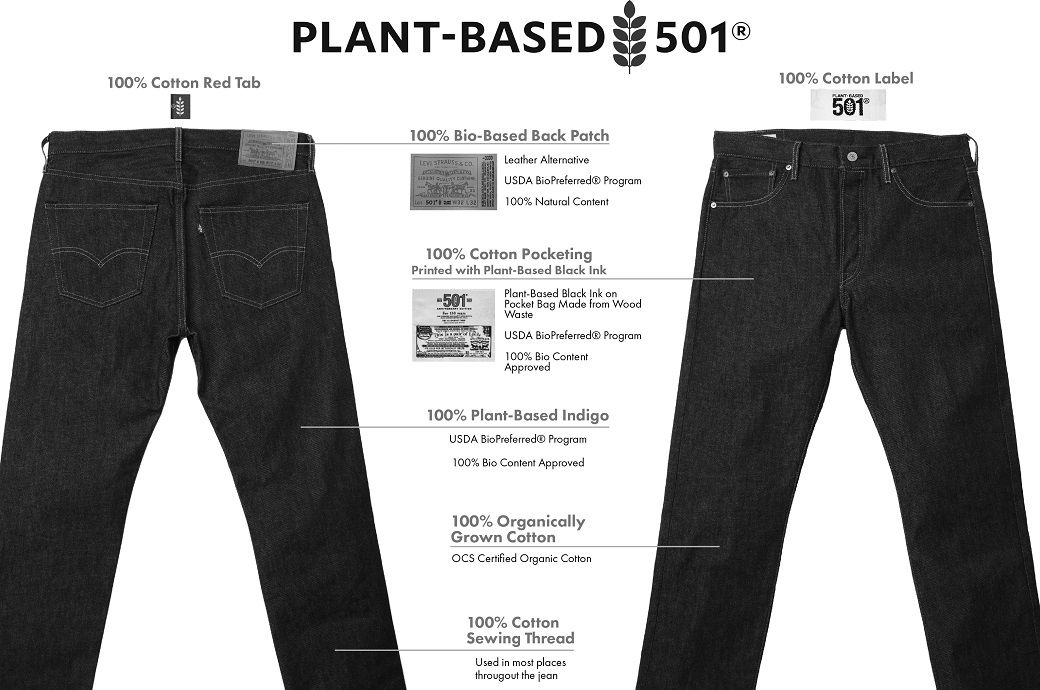

The Plant-Based 501 has a number of unique attributes. For instance, its fabric is made with 100 per cent OCS-certified organically grown cotton and dyed with plant-based indigo from Stony Creek Colors. The denim colour is a nod to Levi’s X80 archival shade.

The garment back patch is made from a material called Mirum by NFW, and is fashioned from 100 per cent biobased, plastic-free inputs generating no effluent in production.

The internal pocket bag is 100 per cent cotton and printed with BioBlack TX, a plant-based black pigment made from wood waste, manufactured in a closed-loop system, and developed by Nature Coatings, another collaborating partner. Woven labels and sewing threads in non-critical areas of the garment are likewise 100 per cent cotton.

Each pair contains at least 97 per cent bio-based content based on components weight measured against overall garment weight. Non-plant-based content includes sew thread, the care label, and metal trims.

“We want to show what is possible,” said Dillinger. “At the same time, we’re challenging ourselves to get closer to a state where products like this represent more of a product line, and where they’re seen not as the endgame, but a starting point that we want to top next season, and the season after that.”

Additionally, building on its efforts with cottonised hemp over the years through its Wellthread line, Levi’s is releasing a hemp/cotton blend Selvedge 501. These will come in a variety of shades and finishes for women and men alike, some featuring natural dyes. They will be released throughout the year, marrying the premium selvedge fabric with the alternative fibre innovation that has characterised so much of Wellthread’s work in recent years.

“In our ongoing research and development, we strive to improve our design practices and conserve environmental resources every way we can,” said Una Murphy, Levi’s director of design innovation. “By incorporating sustainable innovation, in mainline and premium products alike, we learn what’s possible and how we can continue working towards solving some of our biggest challenges.”

Also being highlighted as part of the 150th anniversary celebration is the Circular 501, first released in 2022. This jean is made with a mix of organic cotton and Renewcell’s Circulose fibre, viscose made in part from recycled denim and other forms of textile waste.

The formulation allows the use of far fewer natural resources and chemicals in the production process. Each material component aligns with a strict single-fibre strategy that enables efficient recycling at the end of the garment’s useful life. By replacing parts of the garment that would normally be made from synthetic fibres—like polyester pocketing, threads, labels, and interfacing— with 100 per cent cotton alternatives, synthetic elements have been removed that would otherwise disrupt the cotton recovery process. The result is a new jean made with old jeans that is itself designed to be recyclable, with the potential to be re-made into new jeans, again and again.

“Together, these three versions of one of the most iconic garments in all of apparel, the 501, show that while we are still focused on producing classic garments that consumers have known and loved for decades, we are also looking to improve how we make our products, moving in the direction of more circular products and practices,” said Dillinger.

Fibre2Fashion News Desk (NB)