The researchers reported in in the Journal of Imaging, Science and Technology that certain styles of jeans were easier to replicate using inkjet printing than others, and certain features, like colour, were more easily replicated.

They expect digital printing will be a viable method for making new jean products in the future, with less waste.

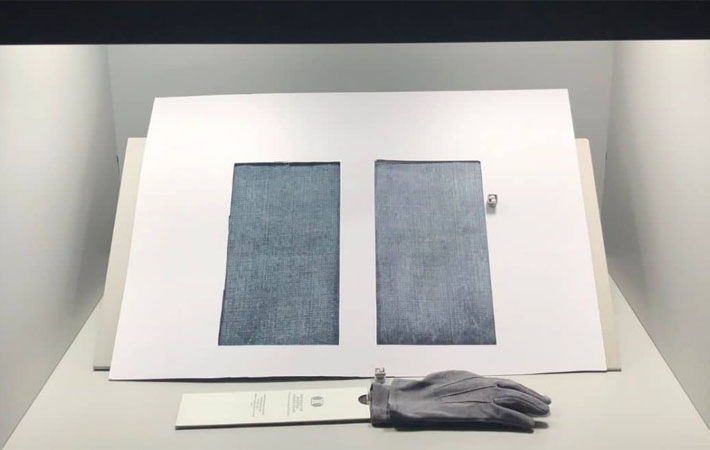

Lead author Ming Wang, a former graduate student there, told a media outlet that Wang a high-resolution scanner was used to scan a very high-resolution image of the jean samples. Then it was transferred to a computer file that can contain the colour and transparency information.

Then a pre-treated fabric was chosen that has the same weight and texture as the traditional jean samples. The more environment-friendly latex printer was used. Six different denim types that have different washing effects were chosen. It was found digital printing can reproduce all of those effects.

Besides colour, the researchers also evaluated the line quality, the texture, the lightness and overall match. What they found is that it is very hard to achieve the line quality and texture. The reason might be that the traditional dyeing has high ink penetration. But for digital printing, it is printing on the surface of the fabric, and not penetrating that much into the fabric. That could cause the difference in line quality and texture.

Study co-author Lisa Chapman, associate professor of textile and apparel technology and management at the university, said while there is a pretty high learning curve for digital printing, there are also advantages with reduced energy use, chemicals and water waste when we are comparing digital printing to screen printing.

Fibre2Fashion News Desk (DS)