Lenzing is also taking on next steps to explore other potential applications, such as in heat seal processes of garments, and seamless stitching processes that involve heat seal adhesive tapes and bonding machines to replace traditional sewing.

“Discolouration has long been a lingering issue for the industry,” said Rex Mok, vice-president of fibre technical marketing and development at Lenzing. “Through ongoing innovation and close collaboration with fabric mill partners, we have not only addressed a common technical challenge, but also enhanced sustainability in the value chain with the potential to increase usage of botanic fibres across innerwear and outdoor garments. The latest technological innovation also speaks to Lenzing’s efforts to improve and widen the application of cellulosic fibres, such as Tencel Lyocell and Modal fibres, which are derived from sustainable wood sources and produced using environmentally responsible processes. This serves as part of our wider commitment to drive the sustainable development of the textile value chain.”

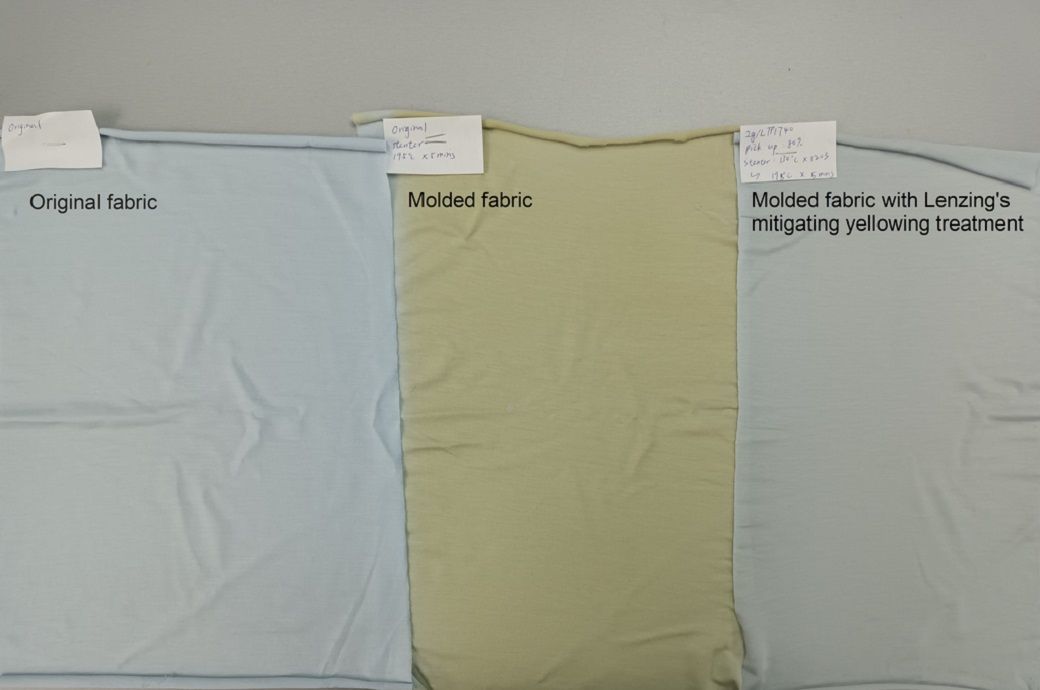

Discolouring and yellowing issues caused by high-temperature molding have traditionally been inevitable during the garment production process. While chemicals could be used to minimise discolouring issues in synthetic fibres, this method does not work as effectively as it does in wood-based cellulosic fibres. With Lenzing’s proprietary solution, such challenge is mitigated, eliminating the bottleneck fabric mills experience during the production and dyeing of light-coloured garments made of wood-based cellulosic fibres, the company said in a press release.

Leveraging the new innovation, Lenzing’s mill partners can now benefit from the adoption of a broader spectrum of colors and shades, bringing more diversified fabric and garment offerings to consumer brands. Given the diversified needs among different mill partners, Lenzing’s technical experts will work closely with fabric mills to provide a technical analysis of fibers and fabrics, recommendations, and ongoing support through to the end-garment stage.

“Our customers have been positive about the visible improvement of the yellowish issues in fabrics during the high temperature molding process. Lenzing team’s processing solution and technical support have made our lives easier, allowing us to find the sweet spot for different combinations of fabrics and colours,” Li Wei, product development manager at Yelin, said.

During the initial phase, the proprietary technology will be used in the production of seamless lingerie and shapewear globally, with a proactive strategy to introduce the technology to outdoor apparel and other ready-to-wear garments thereafter. Waterproof garments, windbreakers, jackets and other weatherproof clothing that are produced using a stitch-free technique or heat seal bonding will also benefit from the increased colour and design possibilities.

Fibre2Fashion News Desk (RR)