The plant will be the first to recover cotton and polyester from blended textile waste.

“We remain excited about this continued collaboration with Andritz. Together, we will commercialise Circ’s innovative recycling process and take another step towards a truly circular fashion industry. With its expertise in engineering and building large-scale process equipment, Andritz is the right partner to help us transform textile waste into recycled fibres on an industrial level,” Conor Hartman, chief operating officer at Circ, said.

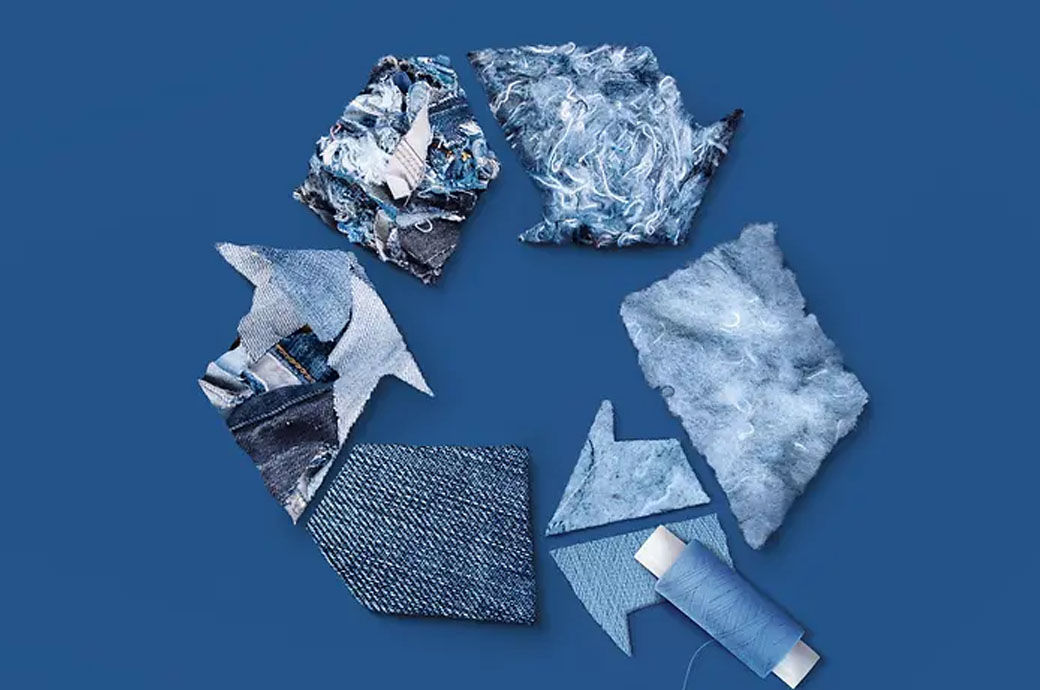

The majority of fashion waste consists of polyester-cotton blends, which poses a significant challenge to achieving greater circularity. In particular, the separation of cellulosic and synthetic fibres from textile waste has been a major obstacle. Circ’s innovative recycling process can break down polycotton textile waste into its original components – polyester and cotton. The forthcoming plant will process 200 tonnes of textile waste per day, allowing cotton to be recycled for lyocell production and polyester to be reused for polyester production. This will reduce the need for virgin raw materials, the company said in a press release.

“We are eager to support Circ in their vision of circularity because the technology they have developed is uniquely suited to solve one of the biggest challenges in fashion waste and recycling. With our holistic knowledge in resizing, mechanical separation, hydrothermal processing, recovery of cellulosic pulp as well as pulp cleaning and pulp drying, we have the right expertise to help them achieve their goals. Our experience in process development and machinery will help bring their innovative recycling technology to life,” Michael Waupotitsch, vice-president, textile recycling at Andritz, said.

Andritz has been successfully conducting trials for Circ at the Andritz fibre R&D centre in Springfield, Ohio, US, for several years. The successful partnership and recent developments have led to the decision to expand this cooperation.

Circ is a pioneering company focused on sustainable solutions for the fashion industry. By converting fashion waste into reusable raw materials for fabrics, Circ reduces the need for petroleum and natural resources. The company’s mission is to build a truly circular economy to protect the planet from the cost of clothing.

Fibre2Fashion News Desk (RR)