The gel-dyeing technology behind Radianza is the key driver for its superior sustainability performance. Water pollution and water consumption are two of the biggest environmental problems facing the fashion industry and conventional dyeing processes contribute immensely towards these two problems. In gel-dyeing, the dye is absorbed in the fibre within 4-5 seconds with close to zero discharge of unused dye and minimum requirement of water. The LCA study of Radianza done by thinkstep shows that a sweater made with Radianza requires 30 litres less water, 25 MJ less energy and 1.45 kg CO2 equivalent lesser Global Warming potential than the one made with conventional acrylic and dyeing process.

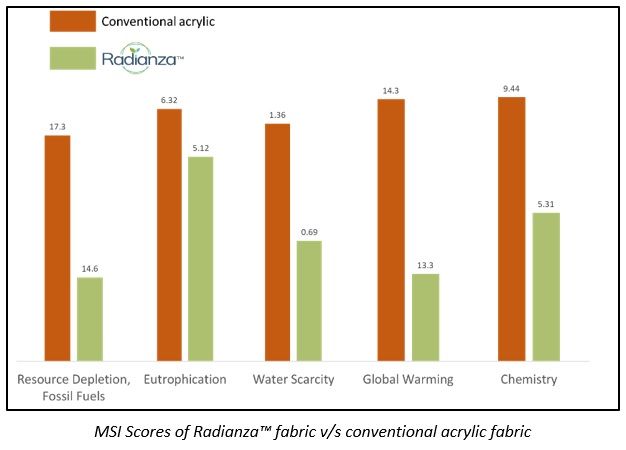

The MSI scores of Radianza also give a similar indication as follows:

An analysis of the above chart shows that switching from conventional acrylic and dyeing process to Radianza:

“We are proud to announce the Higgs MSI Scores of Radianza. This evaluation has re-assured our customers that the use of Radianza in their products will improve the acceptability among the environment conscious consumers, brands and retailers,” says Thomas Varghese, business head – Textiles business of Aditya Birla Group.

The results are expected to be officially published on Higgs Portal by July 2020.

Fibre2Fashion News Desk (RKS)