The fashion industry is an economic colossus, providing jobs to millions around the world. Fashion also makes consumers feel good. But that good feeling comes at an enormous environmental cost, said Barr in an article on JTB Custom.

He added that the rise of fast fashion bears a large portion of the blame for the environmental impact. Another issue is that brands do not know what is going to sell before they go into production as sales forecasts are often educated guesses based on sales of previous styles.

“Without a reliable method to test consumer demand for new styles and colours before production, brands are forced to guess what consumers want. And that leads them to over-order from the factories, because it’s cheaper to double volumes with a factory and deal with the excess later – even if that means sending it to landfills or burning the dead inventory,” the article read.

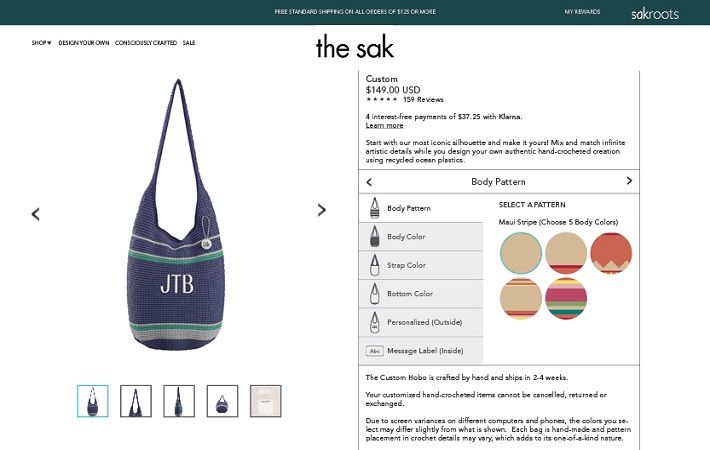

The better way to deal with this is virtual merchandising, and its benefits can be realised without expensive software, said Barr.

“Advanced 3D product models with 2D perspective renderings from a variety of viewing angles provide consumers with hyper-realistic images of the product at significantly lower cost and with no loss of visual appeal,” he said in the article.

The lower-cost, high-resolution 2D solution can help designers test demand for new styles without committing to container loads before they know how consumers will react. Barr added that JTB Custom can help any brand plan and execute on-demand manufacturing with its ‘walk > run > fly’ gradual rollout approach.

“Virtual merchandising may not be a panacea for the environmental costs of fashion, but it is an important arrow in the quiver of countermeasures against this problem – and one to know more about,” concluded Barr.

Fibre2Fashion News Desk (KD)