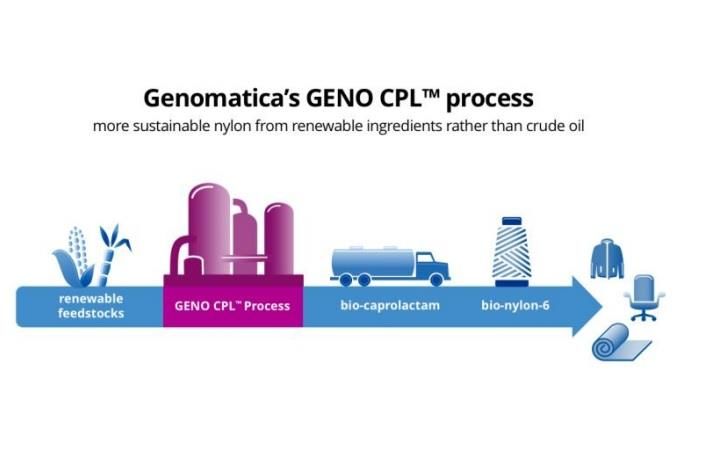

The collaboration aims to develop a commercially-advantageous bioprocess (Genomatica’s GENO CPL process) to make CPL using plant-based renewable ingredients, rather than the crude oil-derived materials traditionally used by the nylon industry.

CPL is used in a variety of nylon-based products including carpets and apparel, and it has a worldwide market of over five million tons per year. Genomatica’s GENO CPL process aims to provide an environmentally-friendly way to make CPL with better economics, including for smaller-scale plants. Additionally, it will enable licensees and their customers to differentiate themselves by offering a more sustainable bio-based product whose performance will be fully comparable with nylon made from crude oil-derived CPL, and which will not require any machine or process adjustments by the nylon supply chain.

Aquafil had launched the ECONYL Regeneration System in 2011 to produce nylon made from 100 per cent regenerated waste. Like the ECONYL process, the GENO CPL process eliminates the significant amount of by-products common to most crude oil-derived CPL production, and will allow producers to diversify their sources in terms of raw material.

“As proven by the success of ECONYL, consumers and manufacturers look forward to opportunities to play an active role in the circular economy. We aim to be a leader of sustainability for nylon, and we are excited by the opportunity to be the first to bring the benefits of this new technology to our customers, which is perfectly in line with our commitment to creating sustainable products,” said Giulio Bonazzi, chairman and CEO of Aquafil. “Genomatica brings the technology, innovation and track record to help us achieve this.”

“Visionary companies like Aquafil are delighting customers and gaining market share through more sustainable products,” said Christophe Schilling, CEO of Genomatica. “This is another example of Genomatica applying the power of biology to rethink how widely-used chemicals can be made a better way. Just as we’ve surpassed key milestones for our commercial GENO BDO process and were named winner of the ICIS Innovation Award for our new naturally sourced butylene glycol, we now aim to bring biotechnology innovation to enable better nylon products.” (RKS)

Fibre2Fashion News Desk – India