The key component ensures an evenly homogeneous melt, influences the increase in viscosity, and hence enables the production of defined rPET preliminary products for further processing such as melt, chips, and fibre materials for direct spinning, Oerlikon said in a press release.

In May 2022, PT Kahatex commissioned a system with a daily capacity of 25 tons for recycling popcorn and bottle flakes into textile-quality chips for manufacturing POY and DTY. Traditionally, Southeast Asia’s largest family-run business is committed to ecological responsibility and is focused on manufacturing high-end textiles for the Asian, US, and European markets. Here, the Indonesian fibre manufacturer is utilising the homogenisation technology provided by OBHE, a joint venture between Oerlikon Barmag and Yangzhou Huitong Chemical Engineering Technique Co Ltd.

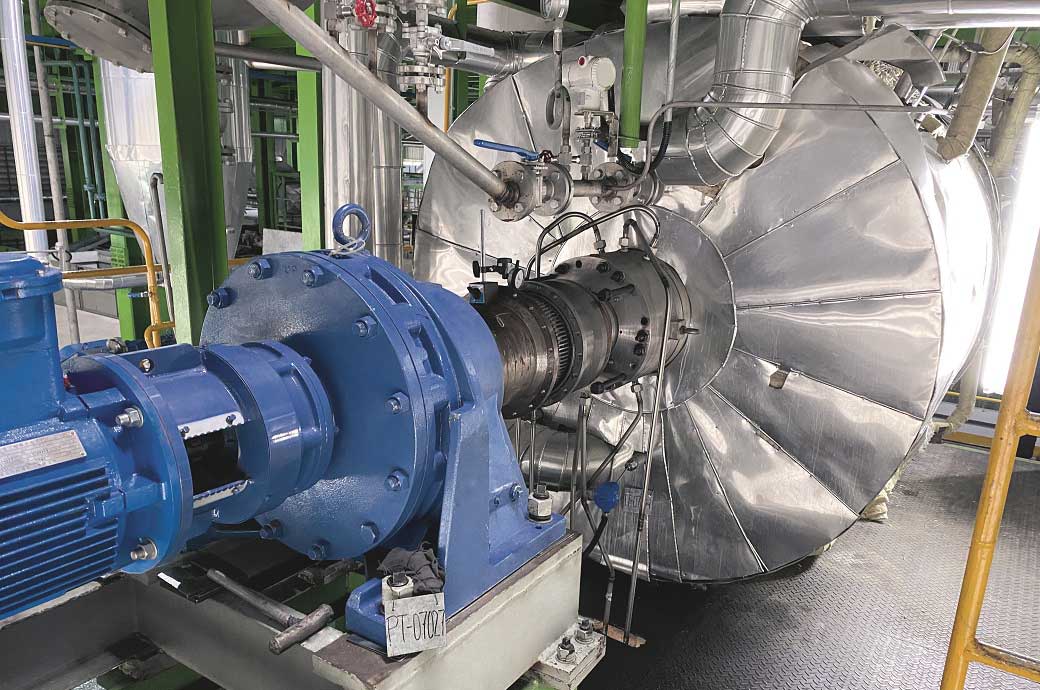

Using the corresponding thermomechanical recycling process, the waste material is extruded and the larger, more solid components filtered out before the homogeniser swings into action. It is in this reactor that the actual mechanical recycling and polycondensation take place. The technology generates a high surface area and—in conjunction with the precisely-defined dwell time—provides more options for influencing the melt. This creates an even, homogeneous melt, while the technology also simplifies the removal of volatile components. In turn, this enables targeted adjustment of the viscosity, which is necessary as the waste material to be processed does not always have the same viscosity.

In this way, spinning system yarn waste—in the form of knotted balls or tangled threads, for instance—is processed into popcorn-shaped agglomerates for extrusion. This popcorn can have viscosity values of 0.6, but also lower values of 0.4. This does not pose a problem as the homogeniser’s increase in viscosity adjusts this.

After exiting the reactor, the melt is once again filtered and finer, gel-containing components are removed. Subsequently, it can be further processed as required, such as in the form of chips or using a direct spinning process and in the manufacture of filament yarns, staple fibres, and nonwovens. The recycling result can only be as good as the processed starting material, as mechanical recycling processes are unable to improve the starting materials and chemical recycling is still in its infancy, added the release.

For this reason, the homogenisation technology remains attractive and is already being utilised by both Kahatex and Chinese fibre manufacturers recycling bottle flakes and yarn waste into staple fibres and filament yarns by means of direct-spinning processes. And the more the industry focuses on recycling systems, the greater the interest.

The technical details for the homogeniser indicate a viscosity range for textile and film between 0.64 to 0.69 dl/g. The operating temperature is approximately 283° C, with the capability for viscosity adjustment up to 0.2 dl/g. In addition, the vacuum jet system operates at roughly 150 Pa.

“We are currently registering enquiries from Bangladesh, but also from China,” said Michael Machtig, product manager at Oerlikon Barmag.

For the purpose of more intensive global marketing, the OBHE technology has therefore been integrated into the Oerlikon Polymer Processing Solutions product portfolio.

Fibre2Fashion News Desk (NB)