Heberlein is known worldwide as a leading provider of air-interlacing and air-texturing jets for synthetic filament yarns. It is also a favourite brand in the Indian man-made yarn community, according to a press release. That position was achieved with the help of an excellent local partner and it is a story that Heberlein staff will share with visitors to the upcoming ITME show.

Heberlein’s history began in 1835 with a big idea and growing enthusiasm for the textile industry. The Swiss company had become well established in the European textile industry as a pioneer in mercerised yarns. Later, a kind of artificial silk known as Helanca, was developed in its laboratories. The final global breakthrough was the development of false-twist texturing machines. Heberlein’s continuing business success made expansion the logical next step, spanning many decades of technological and market growth.

As part of a programme to expand its sales territory into new regions, Heberlein started in India in 1990. A priority was to identify the right partner to ensure a successful market launch. Looking back now, Heberlein is delighted that its search led to Vivek Dhawan, a Bachelor of Textile graduate from Veermata Jijabai Technological Institute (VJTI), Mumbai. Dhawan immediately mounted a tireless effort to run trials all over India with intermingling jets. Customers were soon convinced of the benefits of Heberlein products, especially in Gujarat state where 90 per cent of India’s polyester yarn business is located.

Airotex LLP, the agency representing Heberlein in India, was founded by Dhawan at a time when manufacturers were switching from sizing to intermingled yarn for use in both warp and weft. Texturing was quite new then and producers saw intermingled yarn as a way to avoid the costly process of sizing. As Heberlein’s exclusive partner, Airotex LLP had both the sophisticated solution and the latest technology at hand.

Some Indian customers already knew Heberlein as a spare parts supplier. In components for ARCT/Lohia machines, the quality of spares like spinnerets and Vulkollan rolls supplied by Heberlein was regarded as the best. Later, when intermingling became fully established in the market, the Heberlein name stood out.

For Airotex LLP customers, there are great benefits to be had from in-plant trials of various Heberlein products, carried out by experienced Heberlein staff. These trials help existing and potential customers to evaluate results in terms of interlacing density, level of stability, regularity, or air consumption. The knowledgeable Heberlein support team can recommend the ideal products for specific processes. Such activities build a solid relationship of trust with the clients. And through Airotex LLP, customers benefit from continuous updates on Heberlein’s latest product developments.

Man-made yarn production in India has a 30-year history. In the 1990s, the market started to develop but it was the introduction of intermingling technology which provided the real boost for filament yarn. The market was seeking a definitive shift from sizing to air intermingling, so Heberlein—as a pioneer in air-influenced products—was a perfect partner in the new and growing texturing industry.

“Indian customers appreciate technology from Heberlein for the modification and treatment of synthetic yarns, particularly filament yarns,” said Vivek Dhawan, partner of Airotex LLP.

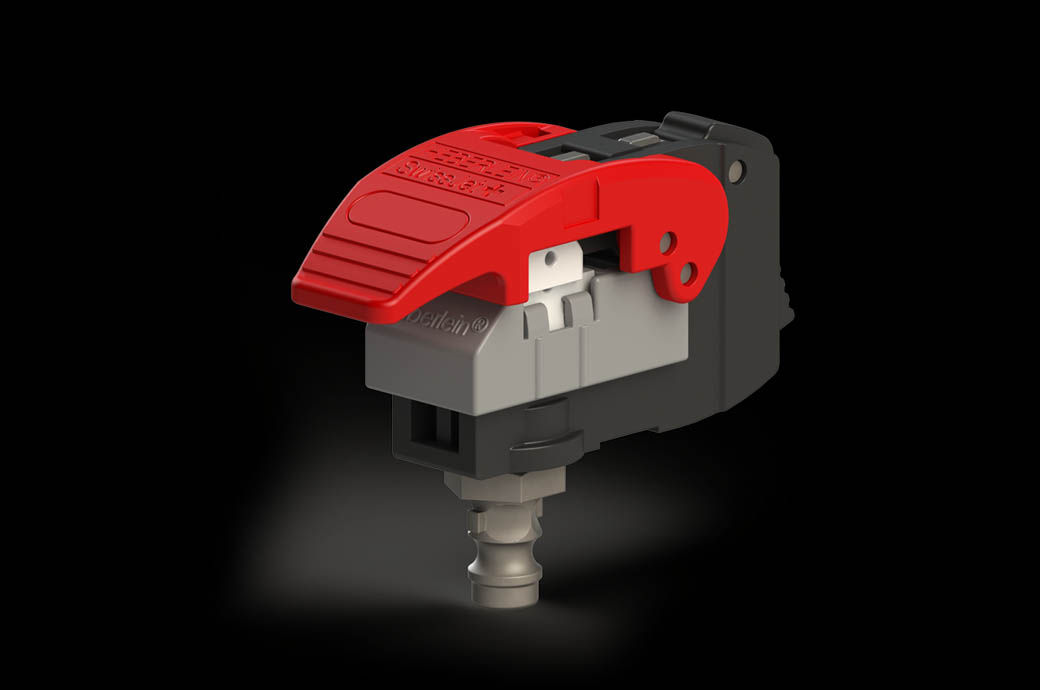

During the past three decades, Heberlein has been pre-eminent with innovative products such as air-interlacing or air-texturing jets for POY/FDY, AirSplicers, suction guns, or cutting heads for polyester staple fibre (PSF) plants.

The most popular products are air-interlacing jets for all deniers from 50 to 1,500 on texturing machines. In texturing jets for 50 to 3,000 den yarn, the company has a virtual monopoly.

Heberlein continuously invests in R&D, with sophisticated, original, and inspiring products and solutions. The company’s success is based on innovation and on customer trust, as Heberlein empowers business success. Knowledge and confidence have both grown, founded on 100 years of expertise. Today, customers rely on Heberlein solutions to meet the toughest processing needs—and create genuine added value. The Heberlein name is a seal of quality, with products renowned for durability, technology, and optimal cost-benefit ratio.

Whenever innovation is required, Indian filament yarn producers know that timely solutions can be expected at the Heberlein textile laboratory in Switzerland. Expert advice on textiles, processes, economic issues, and filament yarns applications is all there for their benefit.

Fibre2Fashion News Desk (NB)