With the JeTex air-texturising system, BBE is expanding its product portfolio in order to be able to offer existing spinning customers in particular, but also new customers, a finishing technology as well. It is a production line for high-quality air-textured yarn (ATY). It combines an innovative texturing system developed by BBE as a key component with state-of-the-art components by Oerlikon Barmag to ensure fast production speed, the desired effects, and the quality of the product, the company said in a press release.

At ITMA, JeTex air-texturising had its market launch. It was impressively demonstrated in the ‘Experience Center’ of the Oerlikon stand, which the visitors gladly took advantage of.

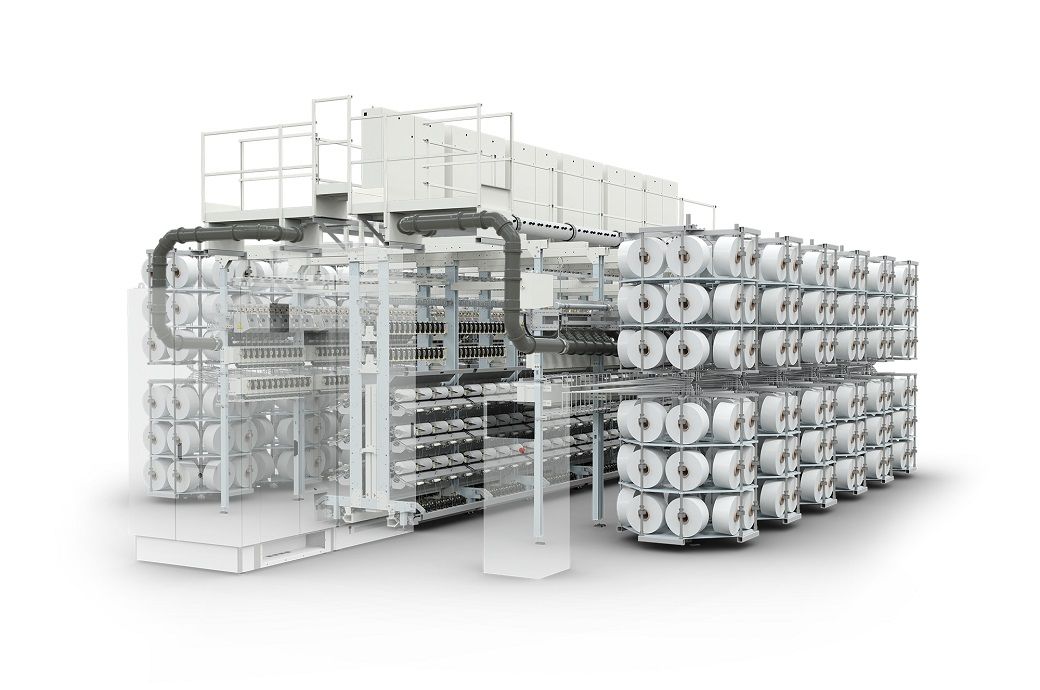

Regarding the proven and popular VarioFil compact spinning line for synthetic fibres, BB Engineering also brought some innovations to ITMA. Higher production capacities per spinning position and improved spin pack lifetime form a new machine generation with increased productivity. The customer’ interest in this was already high in the run-up to the fair and could finally be converted into high order intakes here.

The VacuFil PET recycling system was launched at ITMA 2019 in Barcelona. Over the last four years, BBE has been working on further development and this time presented its solution for waste-free production of filament yarns. The patented liquid-state polycondensation (LSP) unit Visco+ for viscosity adjustment and control as the key component was the main focus and attracted great interest.

In general, BBE assesses ITMA as very positive and full of opportunities. The number of visitors and interest in the topics of synthetic fibre spinning, fibre-to-fibre recycling, and air texturing remained high at the event. In addition to many discussions with existing customers and interested parties, the medium-sized company recorded an unprecedented level of incoming orders.

Fibre2Fashion News Desk (NB)