Lindauer Dornier, a German textile machine and plant manufacturer, has announced that the company is presenting its latest developments in the production of high-quality filter fabrics and future-oriented fibre composite components at the ongoing ITMA Asia + Citme, in Shanghai, from June 12-16, 2021. The company is also presenting its composite systems division.

Lindauer Dornier, a German textile machine and plant manufacturer, has announced that the company is presenting its latest developments in the production of high-quality filter fabrics and future-oriented fibre composite components at ITMA Asia + Citme, in Shanghai, from June 12-16, 2021. The company is also presenting its composite systems division.#

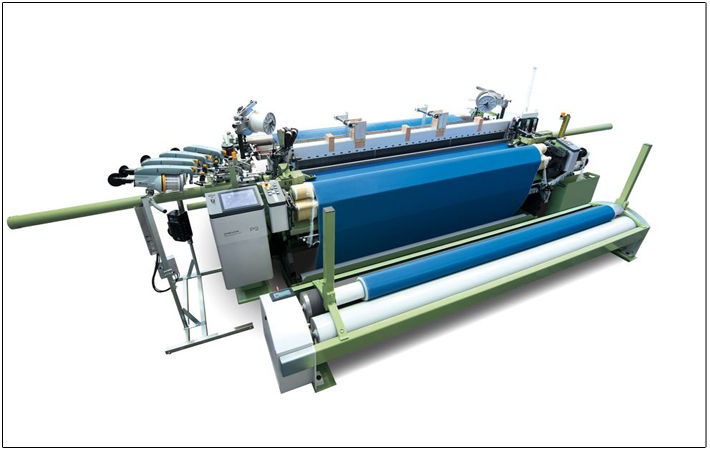

“We have succeeded in launching the most flexible weaving machine in the world,” Wolfgang Schoffl, head of the weaving machine product line at Lindauer Dornier, said in a press release. “We are talking about the P2 rapier weaving machine. It is the successor to the P1, which for years defined the international industry standard in the production of high-performance fabrics. Dornier first presented the P2 in its standard version two years ago at the ITMA in Barcelona. Then came Corona. For a machine and plant manufacturer with an export quota of over 90 per cent, this was initially a bitter blow,” Schoffl added. “But the concern that Corona would slow down the success of the new P2 was unfounded.”

Lindauer Dornier, a German textile machine and plant manufacturer, has announced that the company is presenting its latest developments in the production of high-quality filter fabrics and future-oriented fibre composite components at ITMA Asia + Citme, in Shanghai, from June 12-16, 2021. The company is also presenting its composite systems division.#

According to the company, despite the global cutbacks caused by the pandemic, demand for the P2 rose steadily, for example among technical weavers in the filtration sector. Traditionally, some of the world's largest filter manufacturers rely on rapier and air-jet weaving machines from Dornier. One of them is Jingjin Environmental Protection Inc, China's largest filter manufacturer, who, among other things, produces water filters on these machines. Recently, Jingjin has also started weaving on the P2, whose productivity has been further increased compared to its predecessor, the P1, thanks to improved shed geometry, frame rigidity and a maintenance-free drive.

Lindauer Dornier, a German textile machine and plant manufacturer, has announced that the company is presenting its latest developments in the production of high-quality filter fabrics and future-oriented fibre composite components at ITMA Asia + Citme, in Shanghai, from June 12-16, 2021. The company is also presenting its composite systems division.#

“The great interest in the P2 is also due to the fact that it is available in three versions: with a maximum reed impact of 2.3 t, 3.7 t and 5.0 t. We cover the entire spectrum of fabric production from very fine to very coarse fabrics,” Schöffl said in the release. Because no matter whether water, air, blood or gases are to be filtered, the demand for high-quality filter fabrics is growing worldwide. Among other things, this is due to stricter environmental and sustainability requirements, which demand ever more comprehensive performance parameters.

Lindauer Dornier, a German textile machine and plant manufacturer, has announced that the company is presenting its latest developments in the production of high-quality filter fabrics and future-oriented fibre composite components at ITMA Asia + Citme, in Shanghai, from June 12-16, 2021. The company is also presenting its composite systems division.#

“In order to continuously improve the tightness and quality of filter fabrics, we are further developing our machines in close cooperation with our customers,” Schoffl added.

Lindauer Dornier, a German textile machine and plant manufacturer, has announced that the company is presenting its latest developments in the production of high-quality filter fabrics and future-oriented fibre composite components at ITMA Asia + Citme, in Shanghai, from June 12-16, 2021. The company is also presenting its composite systems division.#

At composite systems division, the newly developed production lines Protos and Tritos are the main focus of interest, as the company said. Both are used to produce highly complex fibre structures and components for lightweight construction.

Lindauer Dornier, a German textile machine and plant manufacturer, has announced that the company is presenting its latest developments in the production of high-quality filter fabrics and future-oriented fibre composite components at ITMA Asia + Citme, in Shanghai, from June 12-16, 2021. The company is also presenting its composite systems division.#

“Dornier customers, for instance, use Protos (polymer and roving to sheet) to produce modern high-performance materials based on unidirectional, thermoplastic continuous fibre reinforcements (UD tapes). They are intended to ensure low weight in vehicles, wind turbines or robots, thereby helping to improve their economic efficiency and sustainability,” the company said.

Lindauer Dornier, a German textile machine and plant manufacturer, has announced that the company is presenting its latest developments in the production of high-quality filter fabrics and future-oriented fibre composite components at ITMA Asia + Citme, in Shanghai, from June 12-16, 2021. The company is also presenting its composite systems division.#

“Tritos (textile roving into three-dimensionally oriented structure) is used, among other things, to create 3D fabrics for aircraft parts. Here, customers benefit from the decades of experience Dornier has gained in the development of machines and systems with customers from the aerospace industry,” the company added in the release.

Lindauer Dornier, a German textile machine and plant manufacturer, has announced that the company is presenting its latest developments in the production of high-quality filter fabrics and future-oriented fibre composite components at ITMA Asia + Citme, in Shanghai, from June 12-16, 2021. The company is also presenting its composite systems division.#

“The demands on material quality and performance of fibre composite components are extremely high in this field,” Josef Klingele, head of the Composite Systems product line said.

Lindauer Dornier, a German textile machine and plant manufacturer, has announced that the company is presenting its latest developments in the production of high-quality filter fabrics and future-oriented fibre composite components at ITMA Asia + Citme, in Shanghai, from June 12-16, 2021. The company is also presenting its composite systems division.#

“With Protos and Tritos, we optimise the manufacturing processes of lightweight construction, today’s megatrend,” Klingele added.

Lindauer Dornier, a German textile machine and plant manufacturer, has announced that the company is presenting its latest developments in the production of high-quality filter fabrics and future-oriented fibre composite components at ITMA Asia + Citme, in Shanghai, from June 12-16, 2021. The company is also presenting its composite systems division.#

The company said that the new Dornier customer portal myDoX is also centre of attention at ITMA Asia. Based on state-of-the-art database technology, it answers the question of how a traditional machine manufacturer handles the virtual data volume of its machines and systems. In addition to online parts order processing and as a substitute for thwarted customer visits and travels, Lindauer Dornier has recently started offering virtual tours. Machines and lines can be viewed digitally according to customer-specific focal points in our Lindau and Esseratsweiler plants: Another essential factor for improving the ecological assessment, given the strong international orientation of German mechanical and plant engineering.

Fibre2Fashion News Desk (JL)