Visitors to the Oerlikon trade fair stand were extremely interested in the new, innovative technology, with business discussions very clearly showing that the new development fulfils the needs of potential clients, the Swiss firm said in a press release.

Visitors to the trade fair spoke about a pioneer for more sustainable staple fibre production. “This shows that our customers have understood that the EvoSteam process has tremendous potential and represents a huge step forward,” commented Martin Rademacher, head of sales Oerlikon Neumag, thrilled by the across-the-board positive trade fair feedback in Milan.

When developing the EvoSteam process, Oerlikon’s engineers focused both on fibre quality and in particular also on sustainability, energy efficiency, and reducing the consumption of resources. Compared to conventional staple fibre systems, an increase in efficiency of up to 12 per cent, a reduction in production waste of up to 50 per cent along with energy savings of up to 8 per cent speak a very clear language. With water savings of up to 10 million litres per annum and a lowering of the carbon footprint by up to 20 per cent, this Oerlikon system helps fibre manufacturers achieve their sustainability targets.

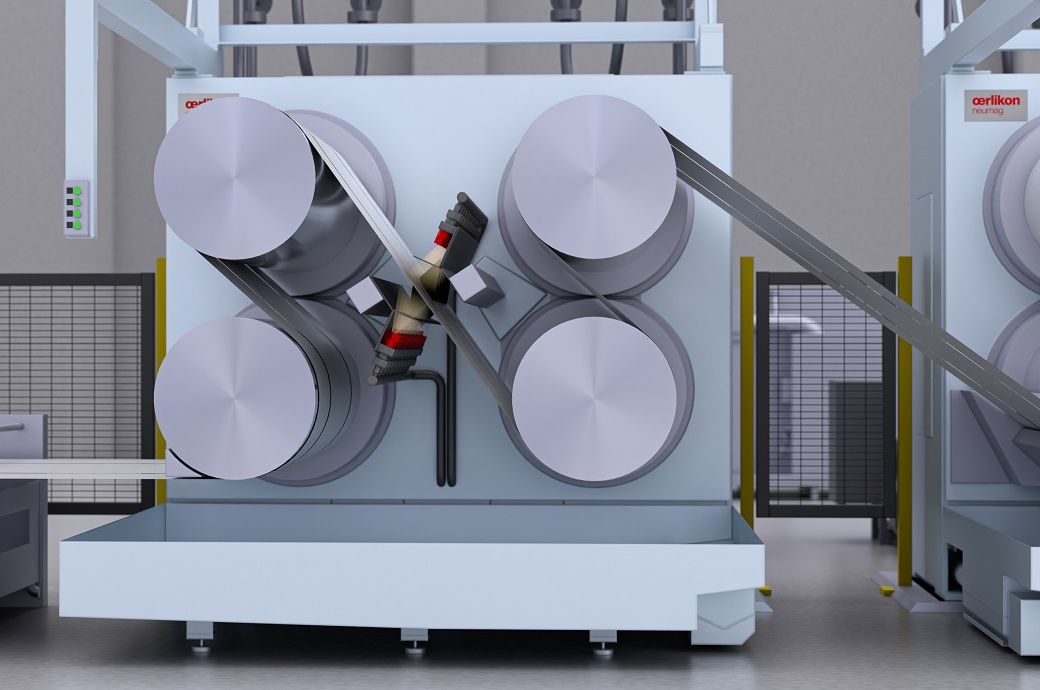

With 10 million litres less water, the function of the immersion bath is assumed by a carefully coordinated setup comprising godets and pulsed spray nozzles. Consequently, moisture is precision-metred and added to the process as required. Completely dispensing with liquid baths generates significant savings in terms of water, energy, and spin finish, while simultaneously also increasing occupational safety and cleanliness at the production line.

“In conventional drawing processes, large volumes of water are used to control the temperature and provide the requisite moisture in the fibre tow. At the end of the process, this water must be removed from the tow again, which is a very resource- and energy-intensive process,” added Rademacher. “The sparing utilisation of water enables a significant reduction in the requisite drying energy, which translates into a tremendous cost benefit for our customers.”

Offering up to 12 per cent superior efficiency, the new optimised draw point release permits higher production speeds and hence increased production volumes. The fibre draw point is released by a precisely focused vapour curtain and is now carried out more evenly and dramatically minimises the friction between the filaments in the tow. In addition, an innovative drive concept reduces yarn slippage on the godets, improves the process stability, and hence increases system availability. Both technological innovations improve the yarn quality demanded by the downstream processes and which play a decisive role for manufacturers’ margins, added the release.

The development focused not only on resource-efficient fibre production and improving the fibre qualities but has also been designed to dramatically reduce the waste generated when manufacturing with this system concept.

“With all the optimisations, we promise a 50 per cent reduction in production waste,” said Rademacher.

Fibre2Fashion News Desk (NB)