Saurer has launched a new portfolio for automation solutions. Textile companies increasingly require comprehensive automation solutions due to greater demands on yarn quality and ease of use as well as the trend towards large and heavy packages. Saurer is a leading globally operating technology group focusing on machinery and components for yarn processing.

Saurer already has 30 years of experience in planning and installation of transport systems, especially between roving frames and ring-spinning machines. The company has successfully implemented over 100 systems worldwide.Saurer has launched a new portfolio for automation solutions. Textile companies increasingly require comprehensive automation solutions due to greater demands on yarn quality and ease of use as well as the trend towards large and heavy packages. Saurer is a leading globally operating technology group focusing on machinery and components for yarn processing.#

The new product line Saurer automation solutions serves as customers’ expert engineering partner for integrated automation solutions across the entire textile value chain. It consists of specially designed automation elements that the project engineering team combines into tailored system solutions that are seamlessly integrated into customers’ processes. Thanks to these solutions, Saurer is meeting the growing demand for cost-effective automation of spinning and further processing in staple fibre spinning and twisting mills as well as in filament yarn processing, the company said in a press release.

Comprehensive data management with innovative quality functions has become indispensable along the entire textile value chain. With Senses, the digital mill management system from Saurer, customers can consolidate and analyse company-wide production, quality and performance data, even for machines from other manufacturers.

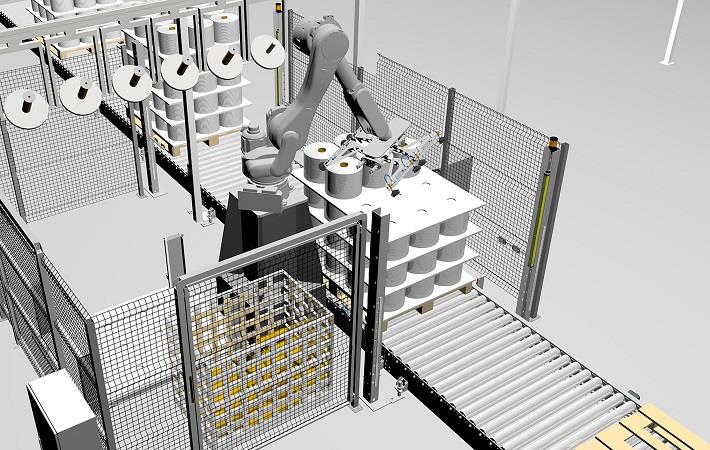

Saurer automation solutions offer tailor-made automation solutions in various areas. In staple fibre spinning and twisting, the solutions can help transport using automated guided vehicles, along with transport systems for roving bobbins, palletising systems, conditioning, packaging, and transport systems for cross-wound packages from the winding/spinning machine to the yarn warehouse.

In filament twisting and cabling, Saurer helps transfer of feed packages with loading units on rail systems for BCF yarns and tire cord for block doffing. It also offers removal of cross-wound twist packages using lifters/rail systems or an automated transport system to the next process step, such as automatic loading of thermosetting systems and weaving creels using robotic units. In the field of project engineering, Saurer offers consulting, project planning, and implementation of custom solutions.

Fibre2Fashion News Desk (GK)