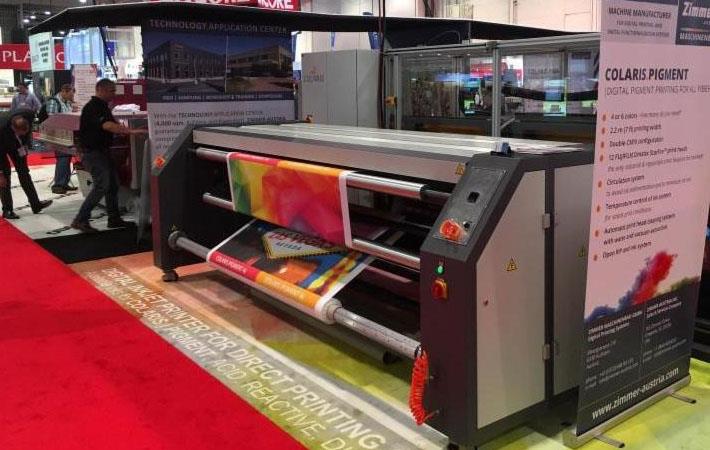

Zimmer Austria, leading textile machinery manufacturer, displayed the new Colaris.12-2200 small production printer during the Specialty Graphic Imaging Association (SGIA) expo. The expo for professionals in the industrial, graphic, garment, textile, electronics, packaging, and commercial printing communities, was held from October 18-20, 2018, in Las Vegas.

The company’s small production digital inkjet printer Colaris.12-2200 ran continuously with pigment inks for the three days of the show. The printer has been met with great interest from the crowd, Zimmer said in a press release.Zimmer Austria, leading textile machinery manufacturer, displayed the new Colaris.12-2200 small production printer during the Specialty Graphic Imaging Association (SGIA) expo. The expo for professionals in the industrial, graphic, garment, textile, electronics, packaging, and commercial printing communities, was held from October 18-20, 2018, in Las Vegas.#

The Colaris.12-2200 is also suitable for acid, disperse, reactive and VAT inks. Zimmer offers a wide range of pre- and post-processing systems and equipment like steamer, washer, hot air dryer, and infrared fixation.

With the new pigment printing solution, Zimmer completes the portfolio of its available ink classes. With pigment inks, very good light fastness, even in the home textiles market, for example, for curtains, or decorative articles are achieved. At the same time, outdoor applications are possible, from sun protection to tarpaulins. With the pigment inks (4 or 6 colours) on the Colaris, reliable printing results with brilliant colours, as well as excellent light, friction and wash resistance are delivered.

To cover all application areas and all ink classes, Zimmer uses various circulating inkjet print heads from the Fujifilm Dimatix StarFire SG1024 family for its Colaris range. This is particularly important for the pigment, disperse or VAT ink classes to ensure reliable production operation. The Colaris models range from compact sample machines up to a 4.2 metres (14 feet) wide system. All models are available in a variety of configurations between four and twelve colours, with a choice between reactive, acid, disperse, pigment or VAT inks. Maintenance is easy and print heads are repairable.

The Magnoroll multipurpose coating machine is the perfect addition for pre- and post-processing to complete the Colaris pigment printing system. Magnoroll is equipped with various modules for universal applications, for example, with Magnoroll magnetic low-add-on system, direct roll coating, screen coating with magnet roll rods or magnet blade squeegee, knife coating. (GK)

Fibre2Fashion News Desk – India