Baldwin and Al Ameen are demonstrating TexCoat G4 in Hall 2 220, and also providing the details on Baldwin’s Plasma Pure corona treatment and TexMoister G2 remoistening systems technologies, according to a press release by Baldwin.

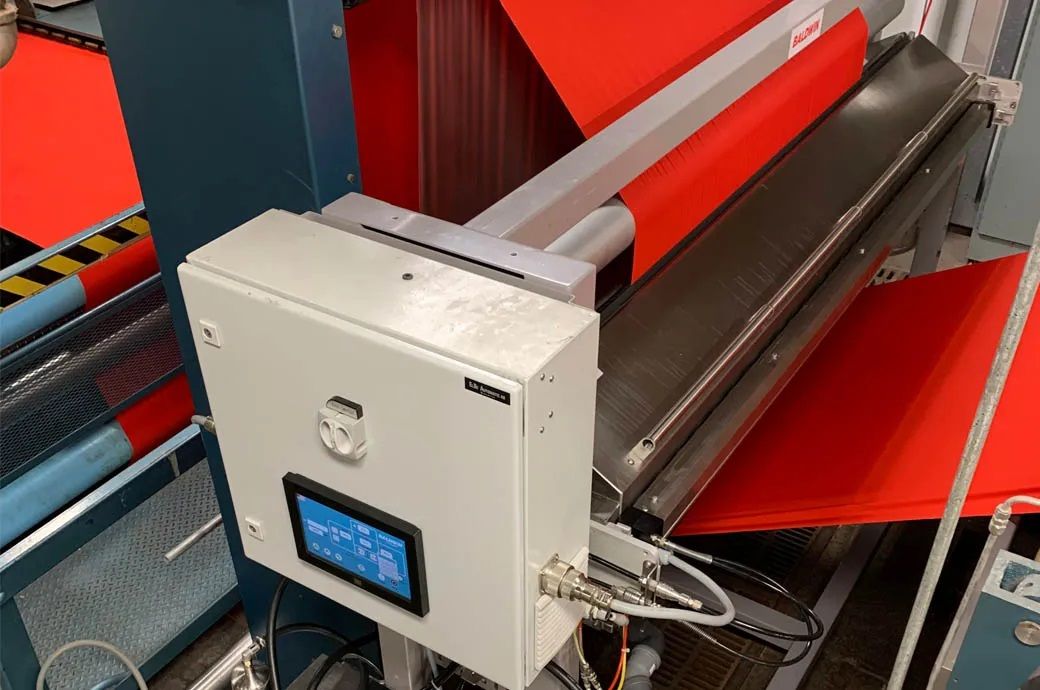

Baldwin’s TexCoat G4 non-contact precision-spray technology helps textile finishers up their game by enabling consistent, high-quality finishing, with zero chemistry waste and drastically minimised water and energy consumption.

With a cost-sensitive global economy and an increased focus by brands and consumers on the environment, customers are placing a premium on sustainability in textile production. TexCoat G4’s non-contact spray technology offers numerous advantages compared to conventional methods of applying finishing chemistry.

With Baldwin’s innovative system, the chemistry is precisely distributed across the textile surface and is applied only where it is required, on one or both sides of the fabric. The non-contact technology eliminates chemistry dilution in wet-on-wet processes, allowing full control of maintaining consistent chemistry coverage rates. Plus, pad bath contamination is eliminated, and changeovers are only required when there is a change of finish chemistry

More specifically, with Baldwin’s TexCoat G4, textile finishers can expect unprecedented tracking and control of the finishing process for consistent quality. Changeovers are easily and quickly performed thanks to recipe management, including automated chemistry and coverage selection. Furthermore, the system offers automated speed tracking, fabric-width compensation, and real-time monitoring to track system uptime, performance, and chemistry usage, as well as active care alerts.

In addition, the TexCoat G4 system can process a wide range of low-viscosity water-based chemicals, such as durable water-repellents, softeners, anti-microbials, flame retardants, and more. Baldwin’s technology utilises the same chemicals used in the traditional pad bath, and no special auxiliaries are required. The recipe is adjusted by increasing the concentration and reducing the pickup by a corresponding amount, so that the same level of solids is applied.

Some applications, such as durable water repellents, are only applied on the face of the fabric, instead of the traditional method of saturation through dipping and squeezing. Drier fabric entering the stenter means lower drying temperatures and faster process speeds. Single-side applications also open up the opportunity to process back-coated or laminated fabrics in a single pass of the stenter, instead of two passes, added the release.

Al Ameen Trading Corporation (Pvt) Ltd has a presence across Pakistan, with offices in five cities, and is celebrating its 75th anniversary. It spans four generations beginning in the 1920s with textile manufacturing with considerable know-how from spinning through dyeing and finishing technology. In 1947, Al Ameen evolved into distribution and representing manufacturers as a sales and service agent. Decades of trust and unwavering values has enabled Al Ameen to be a key industrial partner in process and engineering for the complete textile value chain by its motto ‘Bridging Technology, Fibre to Finish’.

“The textile industry is a very competitive and yet dynamic industry. For sustainability, one needs to save on process costs, at the same time adapt to ecological and greener processes in order to do their part for the environment. Only then, the textile producer will stand out from the rest giving both value and commitment to their buyers,” said KM Khalid, director of Al Ameen Trading. “We saw a great synergy with Baldwin, whose products such as TexCoat G4 allows textile producers to do both at the same time, saving money in the process while being more ecologically friendly. Al Ameen is really excited to have this partnership and looks forward to developing the Pakistan market together with Baldwin.”

“The region (Asia and Pakistan) is without question a key market for Baldwin,” Rick Stanford, Baldwin Technology’s VP of global business development, textiles, emphasised. “Mill owners in Pakistan are very innovative and are keen to implement processes and technology that promote sustainability. We realised that Baldwin’s success in Pakistan requires a strong local partner. Fortunately, Al Ameen, at the recommendation of Archroma, a chemistry supplier and mutual partner, sought us out at Techtextil. We are pleased to partner with Al Ameen and look forward to kicking off our collaboration at Igatex.”

Fibre2Fashion News Desk (NB)