The ready-made garment (RMG) sector of Bangladesh has been the cornerstone of the country’s economy. The industry's contribution to Bangladesh's GDP is significant, with estimates suggesting that it accounts for around 18 per cent of the country's total GDP and was growing at a rate of about 6 per cent, according to IMF data. The official estimate for Bangladesh's GDP was $1.429 trillion at the end of 2023 in purchasing power parity terms.

The industry that has made a crucial contribution to rebuilding the country and its economy is none other than the RMG industry, which is now the single biggest export earner for Bangladesh. The country's apparel exports in 2023 reached a staggering figure of $47.5 billion, accounting for over 86 per cent of the total export earnings from the textiles and apparel industry combined. More than 290,000 registered manufacturing units employ 4.22 million workers in the RMG industry, with strong female participation (41 per cent), according to estimates, which has grown at a rate of about 7 per cent over the years.

Bangladesh remains the second-largest RMG supplier to the world after China. The countries that are lagging include Vietnam, Germany, Italy, and India.

Figure 1: Top apparel supplying countries

Source: ITC TradeMap

Political turmoil: Is it the end of the road for Bangladesh’s RMG industry?

Despite remarkable growth, Bangladesh’s ready-made garment (RMG) industry is facing significant challenges. These include internal issues and increasing competition from countries like Sri Lanka, Vietnam, and India. The current political turmoil, following the resignation and departure of Sheikh Hasina, has led to the closure of the garment industry across Bangladesh, further exacerbating the situation.

Supply chain disruptions due to reduced production: LNG crisis and its repercussions

This disruption is likely to have serious consequences for global fashion and apparel brands like H&M and Zara, which heavily rely on Bangladesh for their manufacturing. Previously, Bangladesh maintained its market share in the RMG sector by leveraging the China-plus-one strategy. However, due to current uncertainties, international buyers might consider a Bangladesh-plus-one strategy, potentially shifting some of their sourcing to other countries. This shift could particularly benefit India’s textile and apparel sector, which may emerge as an alternative manufacturing hub.

The textile industry has been heavily affected by a severe gas shortage since June 2024, leading to a significant drop in production. The gas crisis in Bangladesh has caused a drastic reduction in textile production, with some factories operating at less than 30 per cent capacity and others closing down temporarily. As Bangladesh is one of the world's largest suppliers of textiles and garments, this reduction has created bottlenecks in the global supply chain. This disruption is largely due to damage sustained by one of the two floating LNG terminals in the Bay of Bengal, exacerbated by Cyclone Remal.

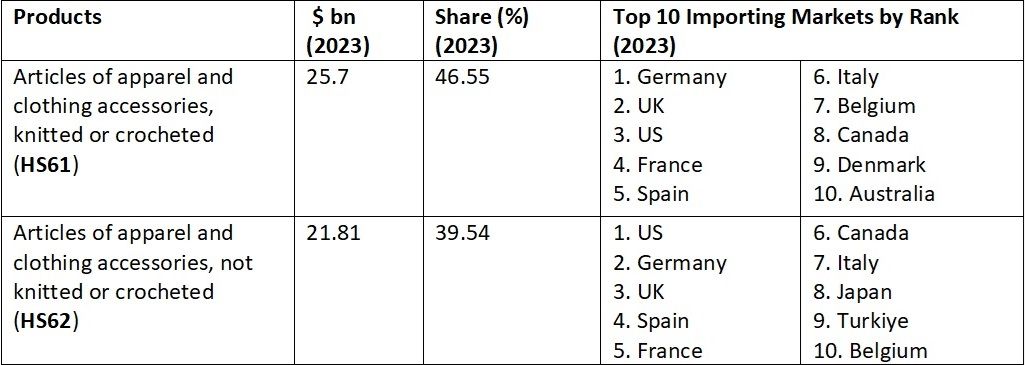

The recent crisis in Bangladesh has significantly disrupted the global supply chain of textiles and apparels, impacting various facets of international trade and industry. See the top 10 countries that are affected on account of instability and production loss in Bangladesh.

Figure 2: Top 10 importing markets by rank (2023)

Source: ITC TradeMap

Increased costs and delays

Many international retail chains rely heavily on Bangladesh for their garment supplies. However, the recent unrest in the country has caused significant delays in garment exports, resulting in massive demurrage charges—a loss for exporters. The internet blackout has also hampered the tracking of garment production. This is not the first time that Bangladesh's textile industry has been affected by such disruptions; last year, protests by garment workers also impacted manufacturing and delivery times for garment exports.

Additionally, with factories operating at reduced capacity or shutting down temporarily due to the gas crisis, the reduced output is leading to further delays in fulfilling orders. Buyers are now forced to either wait longer for their products or seek alternative suppliers, both of which increase costs and complicate logistics.

Major global brands like H&M and Zara, which source a significant portion of their products from Bangladesh, are directly affected. The uncertainty in Bangladesh could force these brands to increase their sourcing costs or delay product launches, thereby impacting their global operations and profitability.

Impact on global apparel markets

The ongoing disruptions in Bangladesh's textile and apparel industry could trigger a significant ripple effect across global markets. Bangladesh is one of the world's largest producers and exporters of ready-made garments, supplying major international retailers with affordable clothing. Any disruption in this supply chain—whether due to political instability, labour strikes, natural disasters, or other unforeseen events—can have far-reaching consequences.

Firstly, reduced output from Bangladesh would lead to a decrease in the global supply of textiles and apparel. Retailers who rely heavily on Bangladeshi manufacturers may face difficulties sourcing their usual volume of goods, forcing them to seek alternative suppliers. However, these alternatives may not be able to match Bangladesh's cost efficiency, leading to increased production costs.

As a result, retailers may be compelled to pass these higher costs onto consumers. This would likely manifest in the form of increased prices for clothing and related products in markets worldwide. Consumers, particularly in countries where affordable fashion is a staple, could feel the impact as they find themselves paying more for the same goods.

Moreover, the ripple effect could extend beyond just price increases. Retailers might also experience delays in product availability, leading to empty shelves or reduced variety in stores. This could, in turn, affect consumer behaviour, as shoppers might reduce discretionary spending or seek out alternative, potentially lower-quality products.

In the long term, if disruptions in Bangladesh persist, the global apparel industry might undergo structural changes. Companies could look to diversify their supply chains, reducing reliance on any single country. While this might mitigate future risks, it could also result in higher costs as manufacturers invest in new production facilities in different regions.

Ultimately, the impact of these disruptions will depend on their duration and severity. A brief disturbance might lead to temporary price hikes and supply shortages, while prolonged disruptions could catalyse significant shifts in the global apparel market, affecting retailers and consumers alike.

Potential shift to alternative suppliers

The ongoing political instability and energy crises in Bangladesh have prompted international buyers to reevaluate their heavy reliance on the country for textile and apparel production. In response to these challenges, some buyers are actively exploring alternative sourcing options in other nations, such as India, Vietnam and Sri Lanka. This strategic shift could potentially lead to a reconfiguration of the global supply chain, with significant implications for Bangladesh's role in the global market.

As international buyers diversify their sourcing strategies, Bangladesh's market share in the global apparel industry could face a decline. Countries like India, Vietnam, and Sri Lanka, which offer competitive production capabilities and a more stable environment, stand to benefit from the diverted demand. These nations could see an influx of new orders, investments in their manufacturing sectors, and overall growth in their share of the global apparel market.

For Bangladesh, this shift could be particularly challenging. The country has long been a dominant player in the industry, thanks to its cost-effective labour force and extensive manufacturing infrastructure. However, the current crises threaten to undermine these advantages, making it less attractive to global buyers who prioritise reliability and consistency in their supply chains.

The reconfiguration of the supply chain could also have broader implications for the global apparel industry. As production becomes more dispersed across multiple countries, the dynamics of competition may shift. Nations that succeed in capturing a larger share of the market could see increased economic growth, while Bangladesh may need to adapt to maintain its position or risk losing its competitive edge.

In the long term, this diversification of sourcing could lead to a more resilient global supply chain, less vulnerable to disruptions in any single country. However, for Bangladesh, the immediate challenge lies in stabilising its political and energy situations to retain the confidence of international buyers and preserve its crucial role in the global apparel market.

Long-term strategic shifts

The ongoing crisis could accelerate a broader trend towards diversifying supply chains, prompting companies to adopt a ‘Bangladesh-plus-one’ strategy, similar to the ‘China-plus-one’ approach seen in previous years. This strategic shift aims to mitigate the risks of over-reliance on a single country by encouraging businesses to source from multiple locations. As a result, supply chains in the textile industry could become more fragmented and geographically dispersed.

These disruptions not only impact the global availability of textiles but also drive-up costs for manufacturers and retailers. Companies may face higher expenses as they invest in new supply chains, while consumers could experience rising prices for apparel and related products.

In the long term, this crisis could lead to a significant reshaping of global supply chains, with greater emphasis on diversification. While this might reduce Bangladesh's dominance in the textile sector, it could also create new opportunities for other countries to gain market share and strengthen their roles in the industry.

The way forward

To address the challenges posed by the current crisis and secure a stable future for Bangladesh's apparel industry, several strategic actions can be considered:

Strengthening political stability and energy infrastructure

Political stability and energy infrastructure: The government and key stakeholders must work towards ensuring a stable political environment, as uncertainty can deter international buyers. Transparent governance, consistent policies, and effective conflict-resolution mechanisms are essential. Additionally, investing in reliable and sustainable energy sources is crucial. Addressing energy shortages through infrastructure improvements, renewable energy projects, and efficient energy management can reduce production disruptions and restore buyer confidence.

Enhancing supply chain resilience

Diversification and technology: Bangladesh should explore diversifying its supply chains by sourcing raw materials from multiple countries, reducing vulnerability to global disruptions. Collaborating with neighbouring countries for shared resources might also be beneficial. Embracing new technologies such as automation, AI, and advanced logistics could help optimise supply chains, improve efficiency, and reduce costs. This would make the industry more competitive and less susceptible to disruptions.

Strengthening industry relations and market diversification

Buyer relations and market diversification: Strengthening relationships with international buyers through transparency, communication, and flexibility can help maintain long-term partnerships, even in times of crisis. Offering competitive pricing, quality assurance, and sustainability initiatives can make Bangladesh an attractive choice despite the current challenges. Expanding into new markets beyond traditional buyers can reduce dependence on specific regions. Exploring opportunities in emerging markets or less saturated regions could open new avenues for growth.

Government and industry collaboration

Public-private partnerships and policy support: The government and industry leaders should collaborate closely to address the crisis. Public-private partnerships can foster innovation, infrastructure development, and policy support, ensuring the industry remains competitive. The government could introduce policies that incentivise innovation, investment in infrastructure, and the adoption of sustainable practices. Providing financial assistance to struggling manufacturers and offering tax benefits for technology adoption could be key initiatives.

E-commerce and digital transformation: The rise of e-commerce requires adaptation. Bangladesh could support manufacturers in developing digital capabilities, enhancing online sales platforms, and integrating with global e-commerce networks.

Reinvigorating trade agreements

Trade Agreements: Bangladesh has signed bilateral trade agreements with 29 countries, including major partners like the US, China, India, and the UK. Additionally, the country participates in several regional trade agreements, such as South Asian Free Trade Area (SAFTA), Asia-Pacific Trade Agreement (APTA), and Bay of Bengal Initiative for Multi-Sectoral Technical and Economic Cooperation (BIMSTEC). Once the government stabilises, there will be a need to reinvigorate these treaties to restore and enhance the focus on Bangladesh's RMG sector.

Conclusion

The future of Bangladesh's textile industry hinges on the ability of the caretaker government, led by Mohammed Yunus, to stabilise the current unrest and restore confidence across all segments of the population. Creating a stable and inclusive environment is essential for fostering trust and cooperation. The government’s efforts to embrace diversification, enhance resilience, and drive innovation will be crucial for the industry's long-term success.

By effectively addressing political and energy challenges, strengthening relationships within the industry, and adopting sustainable practices, Bangladesh can secure its position in the global textile market. These measures will not only help the country navigate the present crisis but also enable it to thrive as the industry undergoes significant transformation.

Fibre2Fashion News Desk (PN)